An Overview of Magnets

2024-12-02 | By Jake Hertz

Most people have been exposed to magnets in their lives, but the mystery of how they work eludes most. As engineers, we know that magnets are a foundational element in modern technology, and the principles of magnetism are fundamental to everything in our world. We’ll discuss the core principles of magnets, their various types, and the myriad applications that rely on their unique properties.

The Science Behind Magnetism

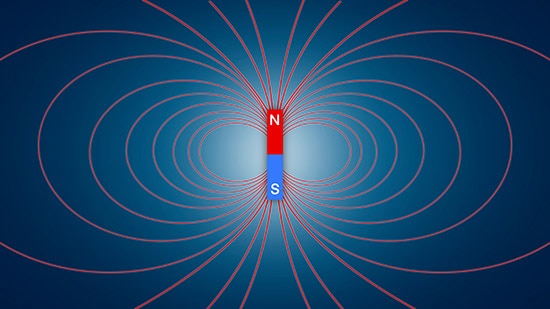

Magnetism results from the movement of electric charges, primarily due to electrons' spin and orbital motions within atoms. In most materials, the individual atoms’ magnetic moments point in random directions, canceling each other out. However, in ferromagnetic materials—like iron, cobalt, and nickel—these magnetic moments can orient in the same direction, producing a collective magnetic field. When a large number of atomic dipoles are aligned in regions called magnetic domains, the material exhibits strong magnetic properties.

Polarization of an axial magnet.

Polarization of an axial magnet.

Magnets interact with their environment through two poles: north and south. Opposite poles attract, while like poles repel. This interaction is what allows magnets to exert forces on each other and on other magnetic materials.

Types of Magnets

Permanent Magnets

Permanent magnets exhibit a constant magnetic field without requiring external energy. They are made from ferromagnetic materials that retain their magnetic properties after being magnetized. The most common types of permanent magnets are:

- Neodymium (NdFeB) Magnets

- Samarium-Cobalt (SmCo) Magnets

- Ferrite (Ceramic) Magnets

Neodymium magnets are the strongest commercially available permanent magnets and exhibit an extremely high magnetic strength-to-weight ratio. A composition of neodymium, iron, and boron, these magnets are widely used in high-performance applications such as electric vehicle motors, wind turbines, hard drives, and MRI machines. Their main limitation is that they lose magnetism at high temperatures, typically above 80°C, unless special heat-resistant grades are used.

Samarium-cobalt magnets offer a compromise between strength and temperature resistance, retaining their magnetism at temperatures as high as 300°C. Their use is often limited by their high cost, which is a result of samarium’s rarity.

Ferrite magnets are made from iron oxide and are the most cost-effective permanent magnets. While they have relatively low magnetic strength, their corrosion resistance and affordability make them useful for everyday applications like refrigerator magnets, small motors, and loudspeakers.

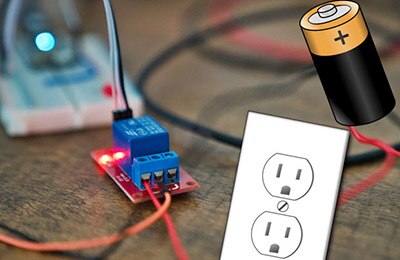

Electromagnets

In an electromagnet, a magnetic field results from current flow through a wire wound into a coil, often around a ferromagnetic core like iron. The magnetic field strength results from the amount of current flowing through the coil and the number of turns in the winding. By varying the current, electromagnets can produce adjustable and reversible magnetic fields, making them essential in many industrial applications. Examples include:

- Transformers: Electromagnets are used in transformers to transfer electrical energy between circuits via magnetic induction.

- Electric Relays and Switches: Electromagnets allow for the remote control of electrical circuits by engaging and disengaging connections when energized.

- Magnetic Lifting Devices: Electromagnets are used in industrial applications to lift and move heavy ferromagnetic objects, such as scrap metal in recycling facilities.

A major advantage of electromagnets is their ability to be switched on and off, enabling dynamic control in applications such as magnetic resonance imaging (MRI) and electromagnetic railguns.

A schematic of a simple electromagnet.

A schematic of a simple electromagnet.

Temporary Magnets

Temporary magnets exhibit magnetic properties only when exposed to a strong external magnetic field. When the field is removed, the material loses its magnetism. Soft iron is a typical example, often used in the cores of electromagnets. Temporary magnets are used in applications where magnetic properties need to be induced temporarily, such as in magnetic clutches or mechanical actuators.

Applications of Magnets

Electric Motors and Generators

Electric motors leverage the interaction between magnetic fields and electrical currents to generate mechanical motion. In a motor, a rotor equipped with permanent, or electromagnets spins within a magnetic field created by stationary magnets or coils. The interaction between the rotating magnetic field and the current-carrying conductors in the motor results in torque, which drives the mechanical output.

Conversely, in a generator, mechanical energy (such as a spinning turbine) causes the rotor to turn, inducing an electrical current in the surrounding coils according to Faraday's law of electromagnetic induction. This process is essential in power generation plants, where mechanical energy from wind, water, or steam is converted into electricity.

A permanent magnet stepper motor.

A permanent magnet stepper motor.

Magnetic Data Storage

Magnetic data storage relies on magnets' ability to store binary information (1s and 0s) by altering the magnetic orientation of particles on a storage medium. Hard disk drives (HDDs) use electromagnets in the read/write heads to modify the magnetic state of the ferromagnetic material coating the disk platters. This enables storing and retrieving massive amounts of data in a compact and cost-effective format.

Medical Imaging and Diagnostics

In the medical field, magnets are central to the operation of MRI machines. MRI technology uses strong electromagnets to align the nuclei of hydrogen atoms in the body. When subjected to radiofrequency pulses, these aligned nuclei produce signals that are detected and transformed into detailed images of the body’s internal structures. The noninvasive and precise nature of MRI has made it indispensable for diagnosing a wide range of medical conditions.

Magnetic Sensors and Positioning Systems

Magnets are integral to many sensor technologies used in industrial and automotive applications. Hall effect sensors, for example, rely on magnetic fields to detect the position, speed, or proximity of moving parts. Modern vehicles use these sensors in anti-lock braking systems (ABS), electronic throttle control, and electric steering systems.

In aerospace, magnetic sensors are used in navigation systems to provide precise positional feedback. Similarly, magnetic encoders in robotics allow for accurate motor speed and position control.

Conclusion

Magnets are essential to the operation of countless technologies that power modern society. Whether in industrial machines, medical imaging, or consumer electronics, magnets enable new applications and technologies that have significantly benefited humanity. Therefore, it is fundamental for engineers and technologists to understand the science behind magnetism, the various types of magnets, and their applications.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.