How Does a Servo Motor Work?

2023-11-13 | By Maker.io Staff

Servos are a common type of actuator often used in various applications ranging from professional-grade robotics to DIY art pieces. However, you might not know that, unlike regular DC motors, there’s more to a servo than first meets the eye. This article investigates the main components of standard servo motors to unravel the mystery behind the often-tiny actuators that enable a vast array of projects.

How Do Servos Compare to Regular Motors?

Compared to conventional DC or AC motors, designed to rotate a shaft around one axis without limiting the number of turns, servo motors usually only turn over a limited number of times — referred to as the turning angle of the servo. In many cases, this angle may be less than 360 degrees, meaning that the servo doesn’t support making a single complete turn in either direction.

Yet, while conventional motors aim to maximize efficiency, they sacrifice rotational angle accuracy and torque, often requiring an external gearbox to drive more substantial loads. Servos, on the other hand, focus on precise turning angles that can often be controlled in single-degree steps, allowing for more exact positioning. In addition, servos usually offer more torque without requiring an external gearbox.

However, servos also have some properties making them not well-suited for specific applications. As mentioned, servos can’t spin freely and are instead limited to a relatively small rotation angle.

Understanding the Main Components of a Servo

A servo motor contains more than you might at first expect. Typically, servos consist of a plastic housing containing three main components: a small DC motor, a gearbox, and control circuitry.

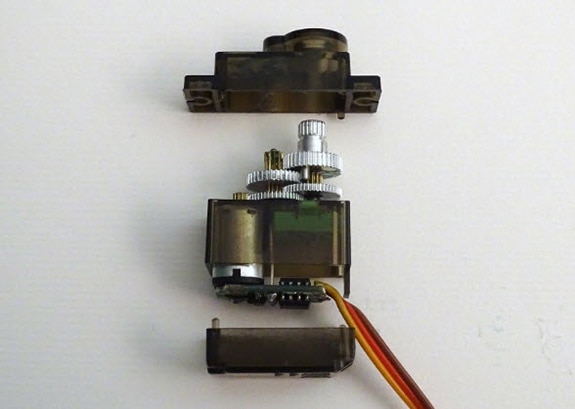

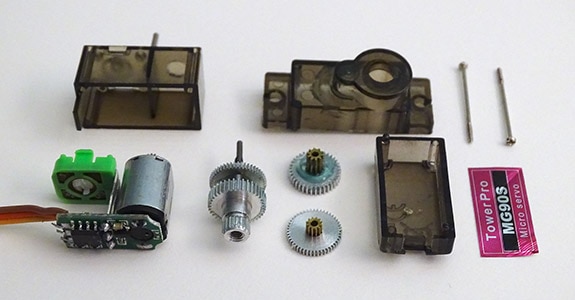

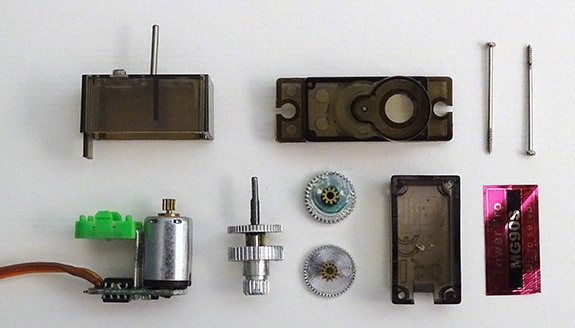

This image shows the main components of a disassembled servo motor.

This image shows the main components of a disassembled servo motor.

The motor provides mechanical power making the servo spin when instructed. The gearbox reduces the motor’s speed, increases torque output, and allows for more precise movement, often in the range of single degrees. The control circuit compares the desired position with the servo’s current state and turns the motor on or off to make the servo’s actuator arm move to the desired position. Servo control circuits usually rely on an internal feedback sensor that reports the motor’s current position back to the control circuit to ensure accurate movement.

Controlling a Servo Motor

While standard motors can be controlled using simple means, such as a digital on/off switch, servo motors require a more specific input signal to function correctly. Most servos expect a pulse-width modulated (PWM) signal with a fixed base frequency (often 50Hz) as input that encodes the target position. The signal’s duty cycle instructs the servo to rotate to a specific angle.

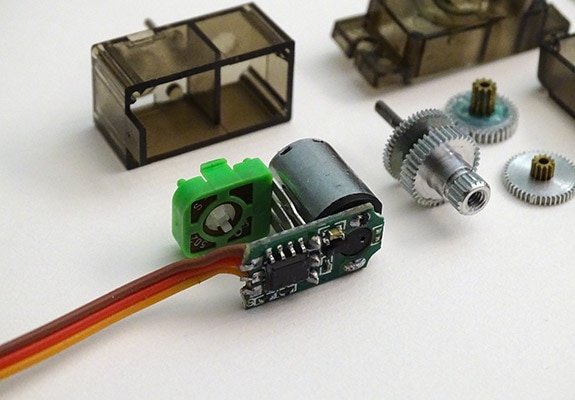

Standard servos contain a controller board that makes the motor rotate and a feedback potentiometer (the bright green part) that reports the current angle to the controller.

Standard servos contain a controller board that makes the motor rotate and a feedback potentiometer (the bright green part) that reports the current angle to the controller.

Usually, servos have a minimum and maximum pulse width corresponding to their minimum and maximum rotation limits. While the exact values can vary depending on the servo model and manufacturer, a pulse width of around one millisecond often corresponds to the minimum turning angle (e.g., zero degrees), and a pulse width of two milliseconds encodes the servo’s maximum turning angle — 180 degrees, for example. The neutral position is usually right between these two extremes. In this example, the servo would turn to its neutral position at 90 degrees when it receives a PWM signal with a pulse width of 1.5ms.

Many devices can generate such PWM signals, and the options range from simple 555-timer circuits to more elaborate servo controller boards or microcontrollers.

Summary

While servos may seem like simple motors from the outside, there’s more hiding within their plastic shell than you might expect. Typical servos contain at least three main components, which are a small motor, a gearbox, and control circuitry with a closed feedback loop.

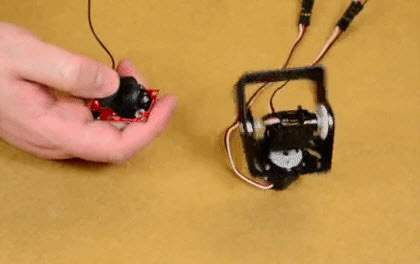

There’s more in a servo than one would expect.

There’s more in a servo than one would expect.

In contrast to regular motors, which can spin their main shaft continuously in either direction, standard servo motors can only rotate around a specific range. However, servos introduce angular accuracy that regular motors lack, making them the perfect choice for many applications that require precise turning and torque control.

Servo motors can be controlled using a pulse-width modulated input signal where the signal’s pulse width encodes the desired position that the servo should move to. By altering the width, a controlling device can instruct the servo to change its rotation angle, often with single-degree accuracy.

Recommended Reading

Pulse Width Modulation (PWM): What Is It? How Can I Use It?