Tackling Dendritic Issues in Soldering

2024-11-22 | By Antonio Velasco

After soldering your PCB and testing it for function, you may think that all of your electrical issues are over. However, as with any project, nothing lasts forever, and various issues may pop up over time. One issue can be dendrites appearing throughout your PCB. No, I don't mean the crucial part of your nervous system that employs electrical signals to control your body (although those are really cool!) I mean the branch-like structures of metal or conductive material that spread throughout your PCB, creating unwanted connections and shorts. Here, we'll discuss how it happens and ways to prevent it.

What Are Dendrites?

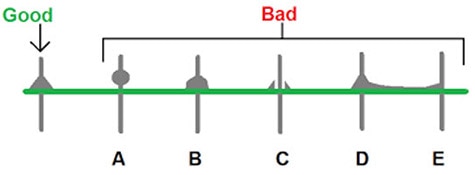

Dendrites get their name from the part of our nervous system that allows electrical signals to go throughout our body. They're very thin and are like tree branches in their shape. On PCBs, they look exactly the same and can appear as corrosion or a very small line:

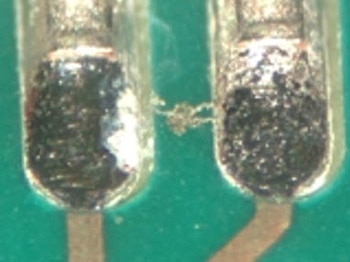

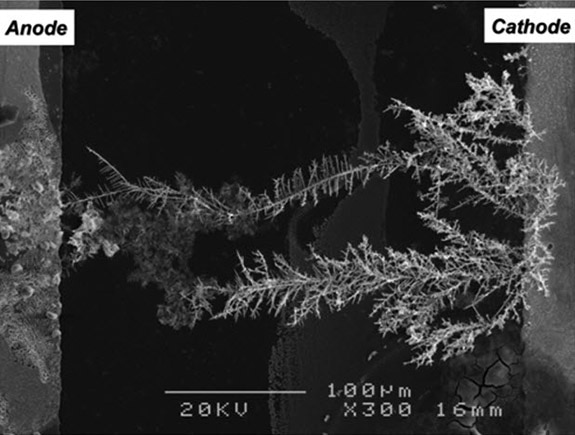

Courtesy of a research paper from the Royal Society of Chemistry, under a microscope, they look like this:

They're very small crystalline structures that form as a result of environmental factors and can cause problems since they essentially connect two nodes or soldered joints that should not be joined. These shorts can mess up any project and, if big enough, can fry a board and the components on it. As a result, it's important to watch out for them and to take the necessary precautions.

What Causes Dendrites?

Dendrites occur simply as a result of metal starting to deposit on the board. This is typically in the form of metal ions coming over from the soldered pins. This can occur for numerous reasons, but the most common tend to be because of an external substance being on the board. Typically, this is some moisture or dirt on the surface of the PCB connecting a couple of nodes. Anything that allows two joints to connect, even if it's only slightly conductive, allows metal ions to pass through and form dendrites.

They can also form as a result of using higher voltages across PCB boards since an electric field may attract ions from another node towards the higher voltage node. Generally, it might be best to stay away from pushing very high voltages through PCBs, though.

How Can I Prevent Dendrites?

To prevent dendrites, make sure to keep the PCB and work area clean. This includes cleaning all flux residue from the PCB after soldering. Also, make sure that the soldered joints are clean and have no protruding or irregular areas. It's also important to make sure that there is good contact and no short circuits to begin with.

It's also important to make sure that no moisture or dirt can build up on the PCB if you're using it frequently. This can be mitigated through using a PCB housing or even just regular brushing/cleaning the board. If you intend on using it in a project for a long time, you can also look into a coating on the PCB to protect it against dirt and other substances.

To prevent dendrite growth as a result of the voltage difference, be mindful of the voltage that you're pushing through the board and take the appropriate precautions. If you must utilize high voltage on the board, provide adequate space between the traces and insulate the board to prevent a strong electric field from forming.

It can also be important to look into utilizing solders that are less susceptible to metal-ion migration. Tin-based solders tend to be very dendrite-prone!

Overall, dendrites are a bit of a tricky problem to deal with. They pop up everywhere, even on consumer electronics. It's important to take the proper precautions and utilize best practices in order to prevent bigger issues later on.