制造商零件编号 4890-18G

SOLDER RA 60/40 .032" POCKET PK

MG Chemicals

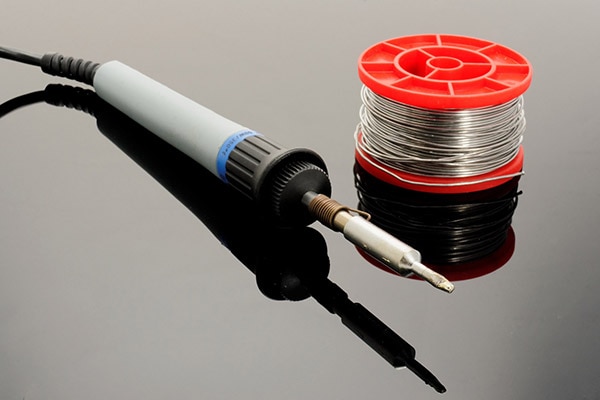

You can choose from a large variety of solder to use in your projects, and it’s easy to get overwhelmed by the choices, as there are various formulations, brands, and sizes to choose from. Further, these products unleash their full potential only when used correctly and in the correct settings. With that in mind, this article introduces the basics of picking solder for an application to get the best possible result consistently. Note that this article focuses primarily on regular manual soldering using standard soldering irons or stations.

Solder is a metal with a low melting point that connects electronic components in a circuit to the PCB or other components. The soldering process can be considered an art form all by itself, and while the skill might be easy to pick up, it’s certainly hard to master. However, choosing the right tools and materials for the job can yield better results.

While solder can be classified according to many different characteristics - like its shape, which could be solid bars, paste, powder, or coiled wire - it’s easiest to group solder into one of three categories: lead-based solder, lead-free solder, and flux-core solder.

Lead-based solder is still commonly used in electronics applications, as it has a low melting point and good flow properties. The 60/40 tin/lead mixture is the most common type and has good tensile and shear strength properties. Lead-free solder generally has a higher melting point than lead-based variants. Several other metals are used in place of lead to achieve specific properties of the finished solder joint, like the prevention of tin whiskers, which happens when solder joints grow tiny whiskers over time.

This image illustrates tin whiskers that can grow over time in specific solder formulations. Note the tiny strands extending from the components' legs and solder pads.

This image illustrates tin whiskers that can grow over time in specific solder formulations. Note the tiny strands extending from the components' legs and solder pads.

Flux-core solder might be the most popular choice, as it combines lead-based or lead-free solder with flux so that you only have to purchase and use a single combined product. In electronics solder, the core is typically a rosin flux, and it helps wet the soldering surface, make the solder flow better, and pre-treat and clean the surface so that the solder can stick better.

Other than tin and lead, solder may contain various other metals that all change a product’s unique properties and the resulting solder joint. For example, antimony increases mechanical strength, bismuth lowers the melting point and inhibits the growth of tin whiskers, and copper lowers the melting point and improves flow properties. In addition, indium is used to solder to gold contacts and in applications that have to function across a wide range of temperatures. Finally, silver improves mechanical strength and resistance to thermal cycles in lead-free solders. However, indium, in particular, is expensive and prone to corrosion, and antimony reduces the flowing characteristics of solder.

Unfortunately, specific solder blends can react with metals used to coat the contacts of electronic components, for example, gold-plated pins, in various ways. However, these factors shouldn’t be too much of a concern for most applications as they mainly impair long-time reliability and specifically apply to industries like automotive companies and aviation, where reliability and fault-tolerance are vital.

There’s an overwhelmingly large number of solder and formulations to choose from, and it’s easy to get dazzled by the options. However, they all break down into three categories: lead-based, lead-free, and flux-core solder. You should be aware that specific solder formulations may have beneficial or detrimental effects on the longevity and reliability of an electronic circuit. However, you can safely stick to standard tin-lead solder for homemade circuits. This type of solder is generally low-cost, readily available, and reliable while simultaneously easy to work with. Some special applications may require more complex formulations to withstand large temperature swings over time.

Three Steps to Cleaning a Soldering Tip