Cleaning PCBs

2016-02-11 | By Joshua Bishop

Some of you may feel you can get away with not cleaning your prototyping PCBs—depending on the locale and design. If that’s the case, good for you! However, despite your fortune thus far, I strongly encourage you to clean your boards. Certain circuits, especially those with sensitive analog circuitry or RF circuits susceptible to minor impedance changes, should be cleaned immediately to make sure performance is not affected. While even the most corrosive flux may not cause any problems in the short term in some environments, over months and years that flux may slowly eat away at that beautiful board you’ve designed. Small traces can open, solder joints can be weakened—the overall robustness of the board will go down.

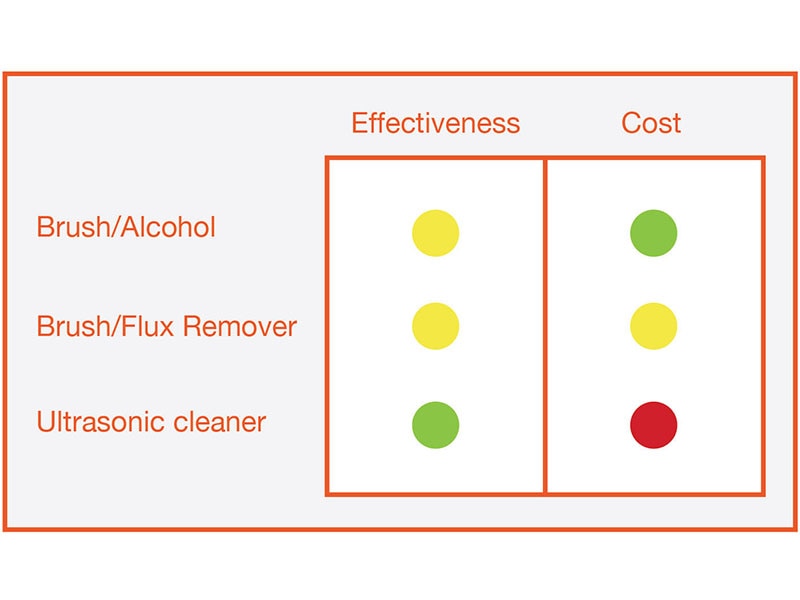

The go-to cleaning kit for any hobbyist or DIYer is isopropyl alcohol and their old toothbrush. If you’re making a small project for yourself, or just making a handful of boards, this is not a bad solution. It removes most of the flux, as well as any other gunk that may be on the board, and should do so without adversely affecting the board’s components. Taking it up a notch, you can use remover designed specifically to remove flux from your boards. Flux remover comes in a variety of strengths. If you’re using a No-Clean Flux (which, honestly, you should clean anyway), then the flux remover doesn’t need to be that strong. If you’re using the same flux for your plumbing and your circuit boards, you want something more robust. While these flux removers are specially made for this purpose, in reality they’re just a blend of chemicals that people typically use when cleaning their boards. On their website, MG Chemicals lists ethyl alcohol, isopropanol, and ethyl acetate as the components of their particular flux remover. Nothing surprising, but they’ve put together a good chemical balance for aggressively cleaning the flux without the risk of eating plastics like the soldermask and IC packages.

While fairly effective, and nicely inexpensive, cleaning boards with isopropyl alcohol and a toothbrush does have its drawbacks. Delicate parts can be destroyed by the stiff bristles, snapping off leads and sending surface mount devices to oblivion. Also, those small parts have small nooks, crannies, and crevices the toothbrush can’t get to. While the alcohol rinse will help, it won’t remove all the flux without some mechanical action. If you use wipes or some non-linting tissue to wipe the boards instead of a brush, it’s even more of an issue to get into those tight spots. For production-quality cleaning, you may want to look into an ultrasonic PCB cleaner. While the price will literally be hundreds of times more than that toothbrush, the cost savings in avoiding returned products as well as hits to your reputation will quickly make it apparent that it’s a wise investment.

A clean board is a long-lasting board. If you want to increase the chance of being able to use your board for years, if not decades, after you make it, clean it. Even if you can only afford a toothbrush and some isopropyl alcohol swabs, that’s better than nothing.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.