Popular 3D Printing Materials and When to Use Them

2021-08-18 | By Maker.io Staff

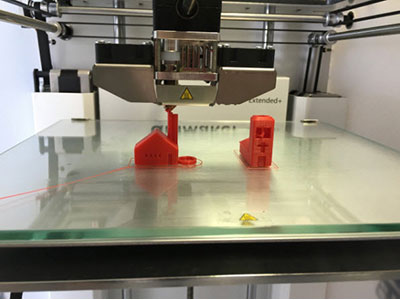

While one can choose from various materials for 3D printing, selecting the correct type of material is critical to achieving successful prints and longevity of the printed parts. Some of these 3D printing materials offer greater strength compared to others, some can produce higher levels of detail, and others are flexible. This article gives you an overview of the most popular FDM 3D printing plastic filaments in the market today and their recommended use cases.

Perfect Materials for Strong, Rigid, and Durable Mechanical Parts

Some of the most commonly used materials in this category include ABS and PETG, which are perfect for manufacturing tough and durable parts. ABS is a material with a long history in home FDM 3D printing, which can be traced back to when desktop 3D printers became common. Therefore, many users are already experienced in using ABS for 3D printing. They might even remember the pungent odor that is always produced when printing with ABS.

Although, in recent years, high-quality ABS filaments tend to give off less odor when printing, which makes ABS a fantastic choice in printing durable parts. In addition, ABS is cheap and readily available. However, one setback of ABS is that they tend to shrink quite a bit when the printed parts cool down, which makes warping a big challenge when using this material. Therefore, as a solution, plan and design your 3D printed parts with slight tolerances and carefully monitor the printer’s temperature.

On the other hand, PETG is typically stronger than ABS, but it usually costs more. Many find it hard to work with PETG, as the material tends to ooze out of the hot end and pull thin strings when the hot end travels. However, compared to ABS, PETG is less prone to warping and shrinking, and the print process does not produce a pungent odor. Parts printed with PETG often develop a glossy finish as they cool, are water-resistant, and are a good choice for outdoor use.

Easy-to-Use Materials for Everyday Applications

PLA is another material with a long tradition in home FDM 3D printing, and it is one of the most popular materials available today. PLA’s popularity comes from how easy it is to use. Since PLA filaments can be printed at low temperatures, a heated bed is not required. Apart from that, PLA is also very cheap and is available in many colors. The material is not prone to warping and excessive shrinking, and finished prints exhibit magnificent levels of detail. Moreover, PLA is typically made from natural starch, for example, corn starch, and thus, is usually biodegradable and easier on the environment than other filaments. Unfortunately, PLA is not the best choice when printing parts for outdoor applications, as the material is not very UV or heat resistant.

UV and Heat-Resistant Materials

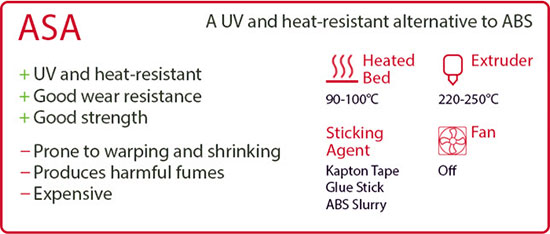

ASA is a commonly used UV and heat-resistant FDM 3D printing material. This material is based on ABS with changes made to the formulation to increase the resistance against UV and heat. However, as ASA shares many common problems often found when printing ABS, this printing material is very difficult to work with. Besides the printing difficulty, ASA is also typically more expensive than ABS. But, on the brighter side, this also means that ASA has similar strength and rigidity as ABS. In addition, when prints succeed, parts created with ASA are very durable and well-suited for harsh outdoor conditions.

Filaments for Printing Flexible Parts and Special Filaments

Flexible 3D printed parts can come in handy in a wide variety of applications, ranging from custom cable ties to soft push buttons in custom-made remote controls. Flexible 3D printing filaments are often referred to as TPE (Thermoplastic Elastomers), and one particularly commonly used material for flexible 3D prints is TPU.

TPEs, regardless of the concrete chemical formulation, typically show high durability and tremendous flexibility, ranging from semi-stiff materials to rubberband-like filaments. Either way, this material is typically very hard to print and is best used by more experienced makers. In addition, when printing TPUs, some of the common problems include poor print bed adhesion, excessive stringing, and poor bridging characteristics.

Support Materials that Enable More Complex Prints

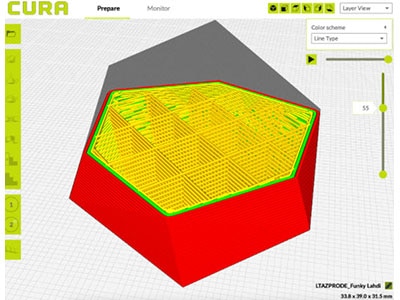

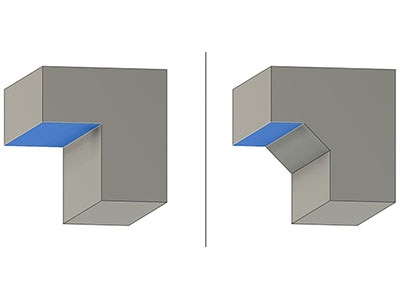

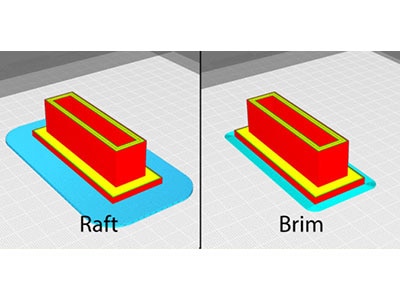

Printing complex models with an FDM 3D printer can often become very challenging since the parts should ideally sit flat on the surface with little to no pieces in the air. However, that is often not possible in the real world. To address this problem, slicing software can generate structures that support parts of the model that do not lay flat on the print bed. Users can decide to utilize the same material they used for the model itself for support. Doing so is especially a good option when using a single extruder 3D printer.

However, various 3D printing support materials are usually aimed at those that use a dual-extruder printer. These support materials are typically designed to work with a specific 3D printing material, such as PLA. The support material is usually very easy to break away by hand or water-soluble. You can choose from various support materials, and every major filament manufacturer offers a range of materials to go along with their main line of filaments.

When you decide to employ support material in your 3D prints, choose the right type for the filament you plan to use. Large suppliers often allow the ordering of samples, so you can test whether you can work with the specific support material, as these special filaments can often be quite expensive.

Choosing the Right 3D Printing Filaments for Your Project

Today, makers can choose from a wide range of FDM 3D printing filaments. PLA and ABS are well-established materials, and they are commonly used. However, other materials, such as PETG, offer greater strength and are often easier to use, even though they are a bit more expensive.

PLA is a great choice for beginners, as it is very easy to work with and does not require any fancy equipment. Furthermore, parts printed with PLA are typically not prone to warping and excessive shrinking. On the other hand, ABS can be a bit more problematic, as the material tends to warp and shrink, and even modern ABS still produces an unpleasant odor when printing.

PETG is similar to ABS, however, the material is less prone to warping, and the finished parts have a smooth finish and are water-resistant. ASA is a derivative of ABS that is perfect for outdoor use. TPEs are a family of flexible 3D printing materials, ranging from rubber-like materials to such that are similar to nylon. TPEs are difficult to work with and are more aimed at those with some experience in 3D printing.

Specialty filaments and support materials can come in handy when printing. However, these filaments are typically expensive, hard to work with, and often require special equipment such as a dual-extruder 3D printer. Overall, it should be a reminder for the makers that selecting the correct type of material is critical to achieving successful prints and longevity of the printed parts.