How I Organize and Keep Track of My Inventory

2025-01-21 | By Zach Hipps

Disorganization affects each person differently. For me, it slows me down, frustrates me, and leaves me uninspired. When I'm building something, one of the most frustrating things that can happen is when I have to stop what I'm doing to go and look for a part. You know what I'm talking about, where you have to go and spend 30 minutes looking for something that should only take 30 seconds. I will show you all the tips and tools I use to get and stay organized.

A year ago, my family and I moved cross-country, and to keep making videos, I had to set up my workshop in record time. Don't let my colorful bins fool you. It's mostly full of miscellaneous junk that belongs somewhere else. I also have some boxes down here that need to be labeled. I have tried to keep organized, but I really need to change something. I spent way too much time looking for parts instead of building things, and that's what I want to change today.

This is a really big project, and I need some help. I have asked my friend Dave to come help me. Dave worked for over 30 years at the Smithsonian Institution as the collections manager for the Department of Anthropology before retiring. He has a lot of experience in organizing things. He was in charge of a collection of about 3.5 million objects. Let’s get started organizing!

I've got three organization zones. I've got one area above my workbench with wall-mounted bins. This is prime real estate for my workshop. What I'm thinking is that the things I use the most often, the things I need to grab the quickest, should be in this area because they're easiest to get to. I've also got a lot of space under my workbenches, and it's wasted space. I'm considering putting things I don't need as often here, but I still want to get to them relatively easily. Then the third area is these big storage bins on racks. That's my long-term storage stuff, which I don't need very often, and I don't need to get to it easily.

Dave offered the following suggestion on how I could use what he did in his last job here in my workshop: “What immediately comes to mind is archeological material, where there are lots of small pieces, and one person might want things organized by a geographic area, but another person might want things organized by a type of object. So, in this case, it's your workshop. You get to choose how it's organized. You're the user.”

I don't want to break my creative flow to go and look for something. Right now, these boxes aren't full of stuff that I need every day. I think we should find everything in my workshop that I want the most accessible, and we put it on this wall above my workbench, where it should only take 30 seconds to find.

I have a big pile of miscellaneous plastic shoe boxes thrown on the table. I call those my boxes of shame, but honestly, everybody who is a maker has boxes of shame like that. The problem is that I need a part, and I shuffle them around, but they continually form a massive, disorganized mess.

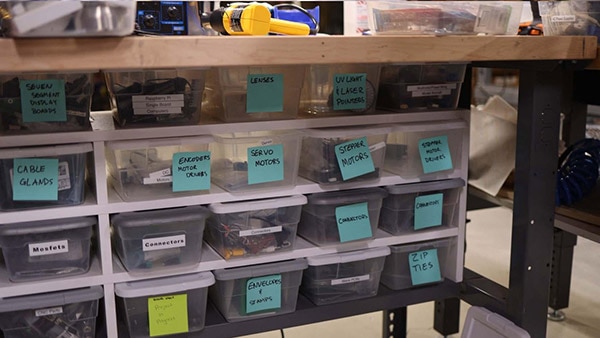

We should start with these black bins on the racks because we can tackle those quickly. Step one is to take everything off the rack and go through all the bins. Then, look for similar items that should go together and for trash and older items that need to be removed and discarded. I see I have a lot of cables. USB cables, Ethernet cables, and cables that go to my oscilloscope are spread out between multiple boxes. That could be one category of items. Finally, if there's one thing I've learned, you must have labels. I will start writing the categories here on the sticky notes, and then we will start consolidating.

I am super impressed with how much space we saved. All the bottom rows of bins are full of stuff, but the upper half of this entire shelf is empty bins. This is so much more functional than it was before. None of this is stuff that I need daily, but it is nice to know that if I need something, it will take me less than five minutes to find what I need now that we've got it all organized.

Next, we will move on to the boxes of shame. The plan is to clear out that space underneath the workbench and use a shelf I previously built to go underneath it. It's designed to fit these bins. We've made a ton of progress cleaning out bins and reorganizing the bins. 48 bins now fit underneath the workbench!

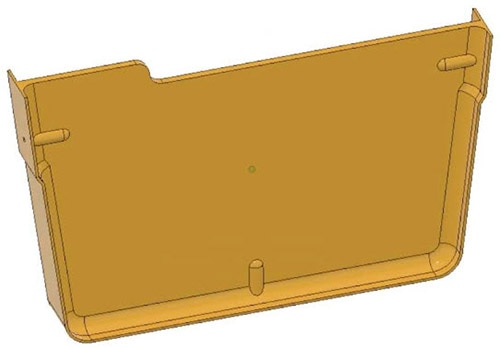

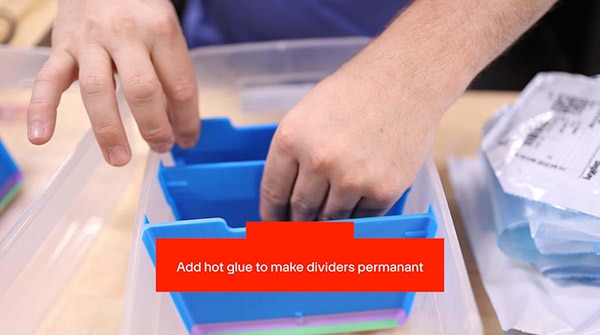

I’d like to tell you what I did with my resistor box. Resistors come in different values, and I didn't want a box full and unorganized of different resistor values. I had to devise a way to divide these boxes even further. I jumped on my computer and 3D-modeled a little divider that fits inside these bins. I didn't want to waste any 3D printing filament before I was sure it fit right. So, I used my laser cutter to cut out some cardboard to ensure I got the template just right before 3D printing, which worked well. I've printed out a bunch of these dividers, which will go inside these bins to break them down even further. This will save me a lot of time when I need to find resistors. I'm going to do the same thing with my capacitors. This is a great way to use up extra rolls of filament you might have lying around.

Now, it's time to move on to the stuff I need the most often, and that's in the blue and red bins above my workbench. A while back, I bought these hanging storage containers. I've got them hanging on louvered steel panels and tried to keep them organized. Some have labels, but I haven't kept up with them. The plan is to do what we did with the first two zones. We will take them all down, set them on the workbench, consolidate what we can, and throw away the stuff I don't need. They are overfilled, and I don't need most of this stuff.

I'm looking through these and noticing some bins I did have labeled correctly. They are things that I use every day, and we should start with those. I will start going through each bin. I will decide if it needs to be thrown away, if it's something I use daily, or if I need to put it down under the workbench. Finally, I'll write a new label. We consolidated so much! Almost half the bins are now empty.

At this point, I'm in the homestretch. I have purged everything that I don't need. Check out all of these bins. They've all been labeled with permanent labels. They are filled with the stuff that I actually use every single day. I've alphabetized all of these blue bins to spend even less time looking for things, and I could stop here, but I really can't help myself.

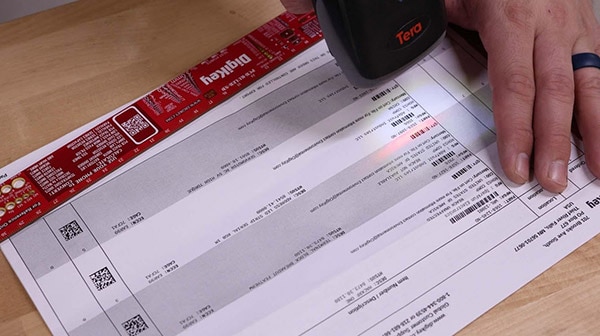

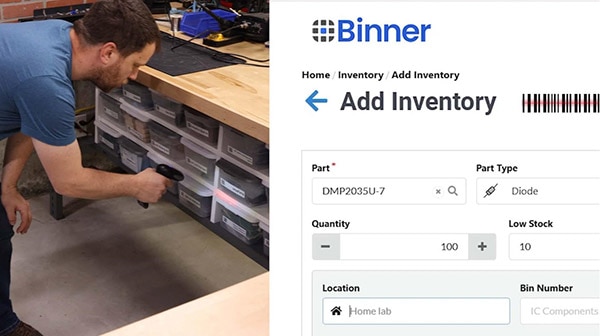

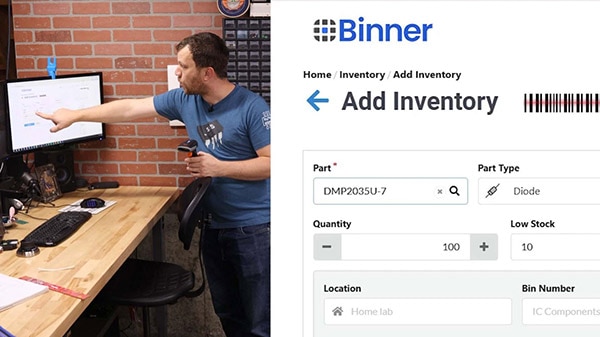

Each label has a QR code, and that's because I'm using an inventory management software called Binner. With Binner, I can take my latest DigiKey order, and I can scan the packages and add them to my inventory. The first thing I want to add is these p-channel MOSFETs. I've got 100 of them and want to add them to my inventory. I've got Binner open on my computer and a barcode scanner connected to the computer. The first step is to click the “Add Inventory” button, and now it's ready for me to scan. I will scan the part number on the packing slip, which then appears on the screen. It even fills in the quantity as 100. That data is contained in that QR code, which is cool. It also found the part number and links to the datasheet. I can click on that if I want additional information about the part. Now I need to tell Binner where I'm going to store it. I click the “Location” tab and walk to my MOSFET bin. I scan the QR code on the MOSFET bin, which tells Binner that the MOSFETs I just scanned will go into that bin.

Another cool feature about Binner is that it integrates with DigiKey’s API. If I had everything set up correctly, I could just type in my DigiKey sales number, and it would import my entire order immediately. Binner could be a useful tool if you're running a production line or manufacturing a product and want to keep track of inventory. It tells you when you're low on stock and when to reorder.

That's an example of adding something to my inventory, but what if I'm in the middle of something and I want to find a component? Binner is about saving time, so I can just go to my computer and type in the necessary component. Let's say I need a low drop-out regulator in this case. So, I type in LDO, and it tells me it's in the “voltage regulator and switch mode power supplies” bin. Now I can walk over, and my bins are in alphabetical order, which saves me time. I know that “voltage regulators and switch mode power supplies” are at the end. Sure enough, here's the part that I needed. Before, I would have probably spent 10 or 15 minutes looking through several boxes, but now, it took me less than 30 seconds to find the part.

This is how I will do everything from now on. Anytime I get parts in, I will first unpack them, scan them, and put them into my inventory. This organizational system is going to save me so much time. I've spent hours and hours and hours digging through boxes, looking for parts, and I don't want to do that anymore. As an engineer, I like to build things. I don't want to search for things; this whole system will help me keep my creative flow going.