Why Does Your 3D Printer Nozzle Clog?

2022-08-24 | By Maker.io Staff

3D Printer 3D Printing Filament

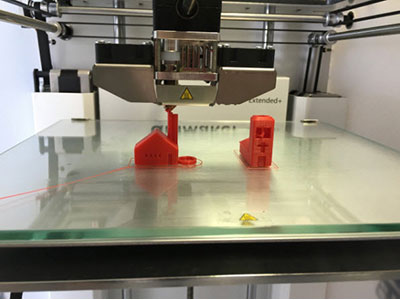

Unfortunately, 3D printer nozzles can easily clog for various reasons, and everyone using a 3D printer regularly knows how frustrating the problems caused by a jammed extruder nozzle can be. Therefore, this article investigates a few common causes for a clogged 3D printer nozzle and also gives a few tips that may help prevent these problems from happening.

Prevent 3D Printer Clogs Early on With Regular Maintenance

Regular maintenance will most likely help you prevent most problems from happening at all. Therefore, ensure not to neglect the hot end and nozzle of your 3D printer when you inspect the device and perform preventive maintenance.

Clean the nozzle using a brass wire brush or some mild abrasive pads. However, don’t scrub aggressively, and don’t use tools such as sandpaper, as they most certainly will scratch and damage the nozzle. Instead, light scrubbing will usually suffice to clean residue and filament deposits off the extruder.

Switching Filaments May Cause Clogs

Switching materials is the next widespread reason for a clogged 3D printer nozzle. Switching from a material or filament that requires higher temperatures, for example, ABS or PETG, to a material that calls for lower print temperatures, such as PLA, may clog the nozzle. The reason behind this problem is that some of the old material remains in the extruder due to the lower temperature needs of the new material. As a result, the old filament will not melt completely, and the residue left behind may cause the nozzle to clog in the long run.

Luckily, this problem is easy to circumvent by pushing enough of the new material through the nozzle to remove all the old filament. Use the old material’s hotter temperature during this process to ensure that the old filament completely melts and gets removed from the nozzle by the new filament.

Filament-Related Issues

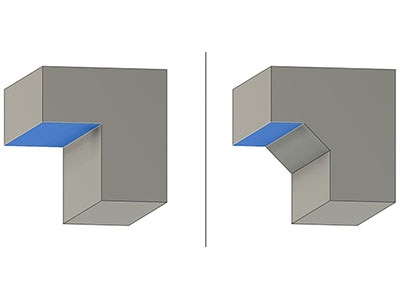

Another common filament-related issue is heat creep. This problem occurs when the heatsink located above the hot end of the 3D printer fails to dissipate enough heat, thereby causing the upper regions of the extruder to heat up. The only parts of the 3D printer that are supposed to get hot are the heater block and the nozzle. Therefore, everything above that region should be as cool as possible.

If the heatsink fails to cool down the upper region of the extruder, some materials, such as PLA, may melt prematurely and cause clogs within the extruder. This problem can be challenging to resolve, depending on how difficult it is to disassemble the extruder.

However, there are a few ways to prevent heat creep from happening. Firstly, ensure that the heat sink and fan can dissipate enough thermal energy, especially after upgrading to a more substantial heating element. The heat sink should be warm to the touch, but it shouldn’t hurt when you touch it.

Heat creep is especially prevalent when using PLA and a printer with an enclosure. Make sure to always let the printer cool down completely before shutting it off.

Heat creep is especially prevalent when using PLA and a printer with an enclosure. Make sure to always let the printer cool down completely before shutting it off.

Lastly, always let the printer cool down after it finishes a print. You’ll notice that the cooling fans typically remain on for a few more minutes to prevent heat creep. You can also leave the door of your enclosure open after the print to cool down the interior more quickly.

Finally, specialty filaments (for example, brands that contain wood grains or metal flakes) may also clog 3D printers, especially when printing with a small diameter nozzle. Therefore, using a larger diameter nozzle may help alleviate this problem. In addition, it may help to increase the print temperature and reduce the print speed.

Extruder Motor and Gear Problems

Lastly, the extruder motor and gears may also be at fault when you notice that your printer jams regularly. The motor may not have enough torque to drive the filament through the nozzle. This problem may occur due to an aging motor, broken hardware, or an incorrect configuration. If you suspect it may be due to a configuration problem, try choosing a larger diameter nozzle, reducing the flow rate in your slicer program, or lowering the print speed.

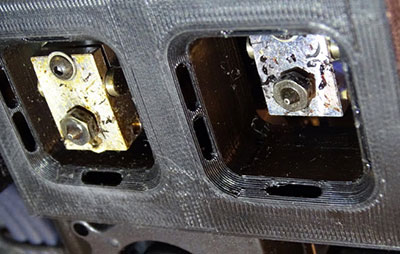

In addition, inspect the gears that push the filament through the hot end. The teeth may contain old material that naturally rubs off due to friction. Finally, the teeth of the hobbed bolt that feeds the filament may also have rubbed off filament that got stuck due to a different problem. In that case, gently clean the teeth so they can grip the filament firmly, which helps the motor push the filament through the printer’s hot end.

Summary

Various reasons may lead to a clogged nozzle and, ultimately, failed prints. First, always clean the nozzle and heater block to remove old, stuck-on residue. When switching materials, continuously extrude the new filament until the remaining old filament is removed from the nozzle. This step is essential when switching from a higher temperature material, for example, ABS, to one that requires lower print temperatures, such as PLA.

Next, ensure that the heatsink and fan of the hot end are operating as they should and that they can dissipate enough heat to keep the upper regions of the extruder cool. Let the fans run after each print and open the enclosure of your printer, if applicable. Finally, inspect the motor and filament pusher gears regularly to detect problems early on. Sometimes, a configuration change, for example, lowering the print speed, can help alleviate issues related to low-torque extruder motors.