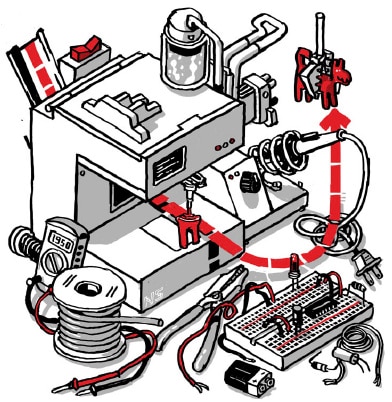

Prototyping

Ladyada's Take

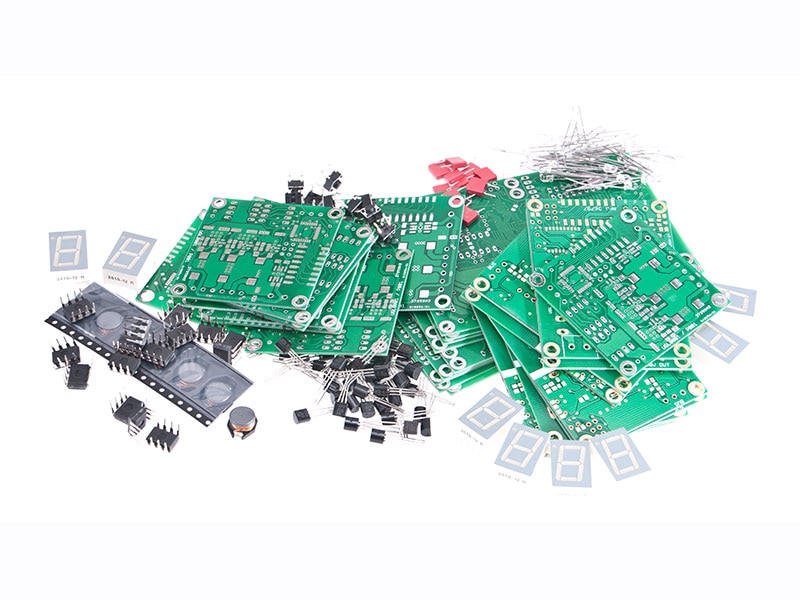

This video, we get back our prototype PCBs! Woo - time to hand solder each component and 'bring up' the board. After each component is soldered in, we test it. We create a 'demo test' that does the te ...

Tools

With the DigiKey BOM Manager, you can now import your Bill of Materials, name and save your BOMs, and choose how to share your designs within your company.

There simply is no better way to find, compare and evaluate electronic components than Digikey.com.

Resources

Having a good relationship and trusting your assembly house is critical. Look for location, type of equipment, quality, certification…

Help is all around and it is important to know where to find skills ...

There are regulations on top of regulations. Make sure you spend the time and money upfront to make ...

There are lots of ways to find a good PCB manufacturer. Make sure you look at location, speed, ...

Understanding what this means to the hobbyist and to the maker is critical. SparkFun does a good job at explaining the ramifications.

Whether you are a 14-year-old maker or a product designer at a Fortune 500 company, you will eventually need manufacturing help. Enter Proto Labs, a digital manufacturer that produces custom prototype ...

中国

中国