Production

Ladyada's Take

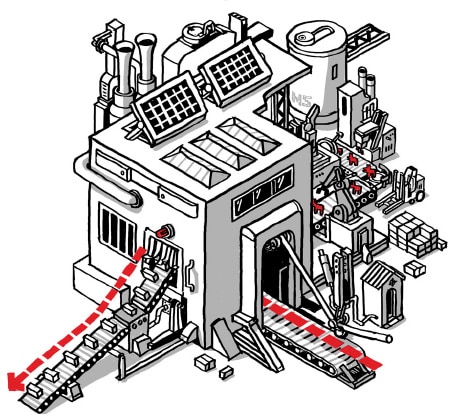

Ahhh, production time. The sweet smell of your final BOM in the air, you’re ready to start making some serious decisions. First, you’ll want to decide what demand might be—how much should you order? Y ...

Tools

With the DigiKey BOM Manager, you can now import your Bill of Materials, name and save your BOMs, and choose how to share your designs within your company.

There simply is no better way to find, compare and evaluate electronic components than Digikey.com.

Resources

Local manufacturing – why it makes sense.

Seeed develops a ...

Your product is ...

Whether you are a 14-year-old maker or ...

It isn't for everyone so think about how well it aligns with your business goals and objectives.

中国

中国