What You Need to Know about Ground Fault Sensing and Protection

投稿人:电子产品

2016-05-05

Electrical ground is an arbitrary point where voltage potentials in an electrical circuit can be referenced. The ground point is usually the lowest potential in the circuit, but does not have to be. Dual-rail amplifiers are examples where voltage potentials below ground are commonly used.

Ground-fault sensing has grown into not only a suggested technology, but a mandated technology for many applications. Bathroom electrical outlets, swimming pool filters, hot tub electrical connections, and many other types of applications require Ground Fault Interrupters (GFI) as a necessary part of an installation.

However, sensing ground faults and disconnecting power is a fairly complex technology and most of us do not have the time or opportunity to become experts in yet another field. Fortunately, technical solutions and resources are readily available. This article looks at ground faults and solutions engineers can use to detect them and protect ourselves and our circuit designs. All parts, datasheets, app notes, white papers, and data referenced here can be found on the DigiKey website.

Static differences

Physical connections to earth as a ground for electrical systems are commonplace for several reasons. Connections to physical ground can limit static-charge buildup that can float to become very high potentials when not referenced or discharged in some way.

What is more, the earth itself is a great conductor and reference. Early telegraph wires could use a single conductor on both ends and the actual earth as the second conductor in a circuit loop. This saves the cost of a second conductor wire that is needed to run long distances. As a result, physical connections of active electronics and electrics will use a long, conductive rod that penetrates deep into the ground for grounding (Figure 1).

Figure 1: Earth-ground connection, as the term suggests, actually relies on connections to the earth which can act as a very reliable conduction path, even over great distances.

Still, just because something is grounded doesn't mean it is safe from posing an electrocution hazard. I myself once was hit by lightning in the basement of my house when the main circuit breakers were turned off. A lightning strike in close proximity to my house created a huge potential in the ground surrounding the house. Even with the circuit breakers of the house turned off, the ground wires still ran to every outlet. In this case, a big arc jumped from a nearby outlet into my leg and down to the concrete floor. I was barefoot (and lucky!).

This is but one example where ground faults can cause serious injury and damage to equipment, even when great pain is taken to provide thick, low-resistance paths to earth ground (Figure 2). As a result, ground fault detection has emerged to try and make equipment and devices safer when high-voltage potentials represent possible danger.

Figure 2: Lightning strikes are an example where large amounts of high-voltage current can flow. However, even heavy-duty low-impedance conductors and bus bases may not be enough to protect people and equipment when very high ground potentials are present.

From the ground up

The ground-fault interrupter, or GFI, is a fast-acting circuit breaker designed to shut off electric power in the event of a ground-fault. It works by comparing the amount of current going to and returning from equipment along the circuit conductors. If you are acquiring a GFI solution from an OEM supplier, then very little digging into the underlying technology is needed. Purchasing and including a certified GFI relay-switched device and including it with your product is the simplest approach.

However, GFI technology is not inexpensive and implementing this technology native to your design may be a better choice from a cost-effectiveness point of view. If this is the case, several good resources are available to discuss the solutions that are best suited for your needs.

One good resource from GE is an app note entitled "Ground Fault Detection in Multiple Source Solidly Grounded Systems"[1] which shows that three wire systems that use an earth-grounded neutral can be architected to make ground fault detection easier by not distributing redundant ground/neutral cabling. This eliminates the possibility of circulating neutral currents and allows individual circuit breakers or relays to cut power during more rapidly sensed dangerous conditions.

Another good resource is a reference design entitled "Shunt-Based Ground Fault Protection for Inverters"[2] from Texas Instruments. Inverters for solar-powered line-fed applications are subject to surges and spikes that can be passed along great distance from power utilities and switching stations. Protection for expensive inverters and solar panels can be a make or break solution to making alternative energy a viable solution.

This case illustrates a 100-volt reference designs using a low-side current-sensing circuit. The differential signal is amplified through a sense current across a low-side shunt resistor. This topology takes advantage of the fact that actual currents flowing does not travel at the speed of light. Sensing at this point can leave more time for drop-out relays and shunts to respond. A similar app note is available for 220-volt designs.

Another good source of learning and information is the Littelfuse white paper "How to use a Sensitive Relay to Find Hard to Spot Ground Faults on Resistance Grounded Systems."[3] Essentially, a window-type Current Transformer (CT) can become a zero-sequence current transformer when all current carrying conductors are passed through the CT window. If there is no ground fault, the output of the CT should be zero. This makes a good solution because if any currents are detected, it means a ground fault is present, and can be used to signal an alarm or trip a disconnect relay.

Available components

In addition to a finished solution, assembly-level and component-level solutions can more easily allow you to implement this functionality into your design. As far as highly integrated primary power switching and sensing units are concerned, finished SPDT-style form 1C AC ground-fault sensing relays like the CR Magnetics CR7310-EH-120-.11-X-CD-ELR-I can be used (Figure 3). These chassis-mounted assemblies handle 20 Amps and trip "without delay" from 0.1 to 1 VAC fault sensing conditions. It is a tough-and-rugged solution with unlimited moisture sensitivity and a –30 to +70 degree operating range.

Figure 3: Ground-Fault Relays monitor real-time ground-fault currents to know when to isolate themselves. This unit includes programmable trip-current settings.

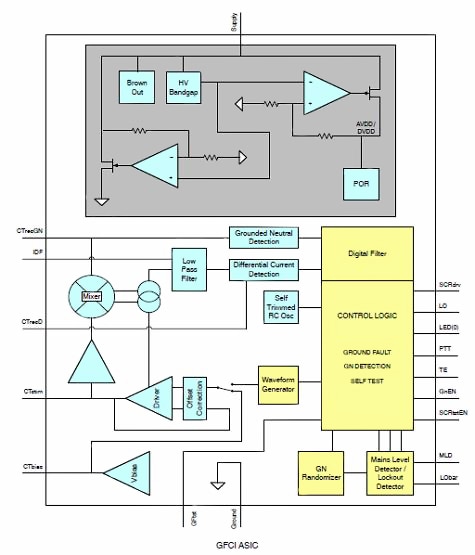

ICs like the ON Semiconductor NCS37010MNTWG GFI controller conform to UL943 mandates and encapsulate all the signal-processing, self-test, and lockout features based on a proprietary impedance measurement technique that uses a specialized DSP controller (Figure 4). This is a hardware-based DSP processing sequencer that includes internal filters which helps assure that no false triggering will lock out power unnecessarily. Designers can choose an external CtresD resistor to set a threshold for sensitivity as well as ground-neutral response times.

Figure 4: Chip-based solutions can integrate rather complex hardware-based DSP functions to implement sensing and control algorithms.

Other possible solutions of interest include Earth Leakage Detectors like the Fairchild KA2807DTF. This 8-pin SOIC can easily be incorporated into power stages of even small equipment, and has a fairly fast 18 msec trip time using a 1000:1 ratio sense coil to reduce surge sensitivity. Isolated current transformers like the CR Magnetics CR8420-1000-G feature this 1000:1 ratio and can make an ideal solution for power frequencies ranging from 20 Hz to 1 KHz. The Fairchild part also provides a 1 mA output current pulse trigger to activate an external SCR which can shunt current directly. You can choose the SCR with its specific size and power rating to suite your specific needs.

In summary

Earth ground is used as a safety reference for higher voltage electric appliances and devices. If we touch a metal conductor that has a net charge built up on it, this can cause an electrical discharge through our bodies that can be fatal. If circuits are referenced to earth ground, and we are referenced to earth ground, then the odds are no high fatal potential differences will arc through us unless there is a real fault with a circuit that exposes us to the higher voltage of the circuit at hand. This article has examined ground faults and solutions that can be used to detect them and protect ourselves and our devices.

For more information about the parts discussed here, use the links provided to access product pages on the DigiKey website.

References:

- GE App Note "Ground Fault Detection in Multiple Source Solidly Grounded Systems"

- Texas Instruments Reference Design "Shunt-Based Ground Fault Protection for Inverters Powered from 100/110 Vac Supply"

- "Shunt-Based Ground Fault Protection for Inverters Powered From 220-V AC Supply"

- Littelfuse App Note "How to use a Sensitive Relay to Find Hard-to-Spot Ground Faults in VFDs on Resistance-Grounded Systems"

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。