Keeping the Smart Grid Smart

投稿人:DigiKey 欧洲编辑

2013-11-21

Smart electronic devices are the eyes and ears of the smart grid, collecting the information utilities needed to minimize the occurrence and duration of outages and balance the flow of energy. With growing consumer energy demands and increasing reliance on distributed solar and wind micro-generators, these intelligent monitors and actuators are needed throughout the network.

The smart grid solution

Energy consumers, the general public, and utility companies are all looking to the smart grid to deliver a large number of benefits. Improving environmental sustainability and reducing carbon emissions are two of the highest profile objectives, championed by governments as well as by popular demand. Utility companies, while embracing the environmental imperative, also see the potential for a smarter grid to deliver improved reliability, help manage aging infrastructure and prioritize new investment, and enhance operational efficiency.

Transitioning from the traditional grid model to a smart grid involves adding intelligence at locations throughout the distribution network. This includes the transmission network, substations, and medium-voltage feeders through to equipment such as smart meters located at customer premises.

Current system architecture and tools

Although the smart grid has become a popular term, the traditional grid is already highly evolved to enable distribution companies to manage their networks responsively, and monitor continuously in real-time to deliver the service that customers need and expect. Key metrics describing the performance of distribution companies include the Customer Average Interruption Duration Index (CAIDI) and System Average Interruption Duration Index (SAIDI). To satisfy customers and other stakeholders, operators must continuously monitor outage status, and respond effectively by deploying repair teams and reconfiguring the grid to manage outages and balance the grid as energy supply and loading fluctuate.

Continuous modernization has seen the deployment of SCADA systems at the substation level, which have also extended into the medium-voltage feeder infrastructure. Figure 1 illustrates the types of equipment deployed in the key substation, feeder and customer zones of a typical electricity distribution network. In addition, utilities have implemented centralized Outage Management Systems (OMS) to replace manual methods of reporting and tracking outages, as well as Distribution Management Systems (DMS) to help improve system awareness, anticipate and respond to overloads, and improve fault handling, asset utilization, and energy efficiency. Common DMS applications include determining line currents and node voltages in each phase to provide analysis of unbalanced load flows, handling measured and calculated data to improve load flow and help avoid overloads, Volt/VAR control to optimize voltage profiles and reduce peak load and system losses, and remote switching and restoration, enabling the network to adapt to changing operating conditions.

Moves towards a smarter grid are seen in the form of greater integration between the SCADA and DMS throughout the transmission network and medium-voltage equipment. Moreover, as utilities roll-out Advanced Metering Infrastructure (AMI), the integration of AMI data with the DMS is a defining aspect of the smart grid. The integration of AMI data with DMS applications is expected to deliver benefits such as shorter outage duration, better management of system loading, and improved voltage profiles. From the customer’s perspective, smart meters are intended to increase awareness of energy usage, including real-time and historical information, which should help reduce overall energy consumption. This simplifies network-management challenges for utility companies, while empowering consumers to reduce their own energy bills.

Smartening the distribution network

A growing number of smart devices are being installed in substations and distribution systems. These include intelligent controls for voltage regulators used for volt/VAR control, and line reclosers and switches used for tasks such as automatic switching, fault isolation, and automatic restoration after temporary faults.

The use of serial communication protocols for communicating with intelligent controllers, or integrated devices such as smart reclosers, is giving way to Ethernet-based networking using the latest IEC 61850 communication standard. In addition to promoting interoperability and eliminating protocol diversity, IEC 61850 incorporates the GOOSE (Generic Object Oriented Substation Events) protection-speed messaging protocol, which enables high-speed protection, transfer switching, fault isolation, and service restoration. The high speed of the GOOSE protocol allows intelligent controllers or smart reclosers communicating on a peer-to-peer basis to identify the location of a fault, and therefore avoid the voltage disturbances caused by repeated actuation of conventional reclosers. When the fault is pinpointed, the operator can take the correct remedial action to restore service and repair the fault.

To implement comprehensive measurement, protection and automation functionalities at the recloser level, multiple voltage sensors and current transformers are required. Current transformers are used to measure the current in each phase accurately. CR Magnetics has a range of commercial and metering-class current transformers, which can be used for various monitoring and fault-detection duties and includes devices rated up to 4000 A. The metering-class transformers provide high accuracy and minimum phase-angle error. Current transformers allow non-contact monitoring of the current in a conductor by passing the conductor through the transformer’s central window. The CR Magnetics range features square and circular current transformers including the CR7310, which can be used for detecting ground faults or other causes of 3-phase imbalance. All three phases and neutrals are routed through the transformer window, and the sum of the 3-phase Y currents is expected to be zero when the loads are equal. If there is an imbalance, the phases do not cancel and the relay trips.

Smart meters reach the customer

While IEC 61850 communication over Ethernet is becoming more widely used at the substation and feeder level, power line communication (PLC) using a protocol such as IEC 61334, PRIME (PoweRline Intelligent Metering Evolution), or G3-PLC enables utilities to leverage their existing power line infrastructure to communicate with smart meters installed at customer premises. Low-frequency narrowband PLC is typically used, at frequencies up to 500 kHz.

The underlying functional elements of a smart meter, which comprise analog measurement, processing and communications, may be implemented using discrete Analog Front-End (AFE), processor and communication modem components, or using a more integrated approach.

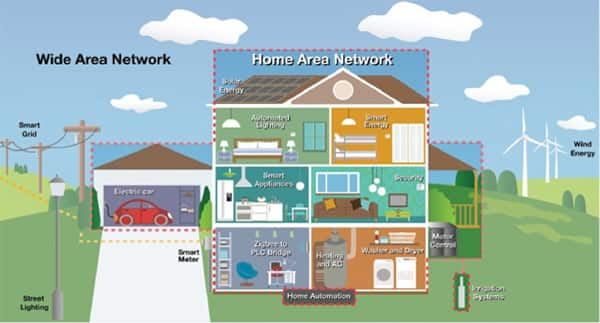

Texas Instruments’ TMS320F28 PLC microcontroller seeks to simplify design while preserving flexibility by integrating the PLC modem functionality and providing a development platform including a PLC modem hardware-configuration tool and the plcSUITE™ software framework. This platform allows developers to quickly develop and test robust PLC implementations and provides flexibility to separate the modulation implementation, the protocol design, and the development of the application. The platform provides a graphical user interface that helps developers visualize and fine-tune key PLC modem performance parameters. Combined, this modular hardware architecture and flexible software framework creates the industry’s only PLC technology capable of supporting multiple standards and modulation schemes with a single platform. Developers can use this platform to create a variety of PLC solutions for smart-energy applications, as shown in Figure 2, with the flexibility to adapt as the applicable standards evolve.

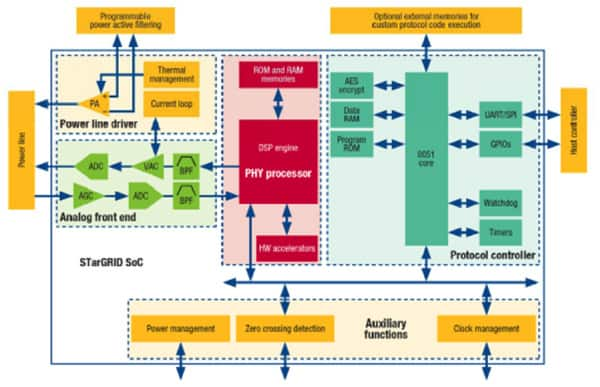

STMicroelectronics has combined processing functionality, PLC modem, and analog front-end into a single System-on-Chip (SoC) device in its STarGRID family of PLC SoCs. As Figure 3 illustrates, the STarGRID platform includes an 8051 processor core for protocol control duties, combined with a separate DSP, giving the flexibility to support multiple modulation schemes. The power line driver, analog front-end, and auxiliary functions such as power and clock management are also integrated. The family of devices includes the ST7580, which is currently being used in 13 million smart meters by the utility companies ENEL and ENDESA, which have operations in southern Europe and Latin America. A similar device, the ST7590, is certified by the PRIME Alliance and used by the Spanish energy group Iberdrola in the 11 million meters deployed as part of its STAR project.

Controlling the new functionality

The design of today’s electronic smart meters takes advantage of remote communications, via PLC or wireless, to implement features and capabilities that have not been possible with traditional electromechanical meters. Among these is the service-disconnect switch, which is used to disconnect a property from the grid for safety reasons such as if the premises are unoccupied or during maintenance or emergencies. By integrating this function as an electronically-controlled switch in the smart meter, it can be actuated from a remote location. This not only allows safety or emergency disconnect instructions to be carried out quickly and efficiently, but also gives utility companies extra flexibility to manage demand and maintain grid stability and voltage levels. The switch is typically a dual-coil polarized latching relay, which requires no holding current to maintain the contacts in either an open or closed state. To ensure reliable delivery of relay-control pulses generated by the microcontroller, and minimize the possibility of tampering, a suitable relay driver such as the Fairchild Semiconductor FAN324x may be used. The FAN3240 has outputs rated for operation from 8 V to 60 V, and integrates a filter/timer block that prevents inadvertent switching from noisy input signals.

Conclusion

The transition to a smart grid is an ongoing process that applies to the entire electricity transmission and distribution network, and has already been taking place for some time. Distribution companies have been using data from SCADA in progressively smarter ways, and driving SCADA further into the network in pursuit of the same goals that are associated with the smart grid as it is understood today. Smart meters capable of providing richer data both to utilities and consumers, represent the final link, bringing smart technology into customers’ premises and general public awareness.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国