Repurpose EV Charging Cables for Industrial Applications

The rapid adoption of electric vehicles (EVs) has spawned a thriving market for standardized charging infrastructure, particularly charging cables. Although designed for automotive requirements, EV charging cables can be repurposed for many other applications that require reliable, high-power connections.

This approach offers substantial benefits. The automotive industry’s investment in EV technology has accelerated innovation while reducing costs. What’s more, the development of connector standards means that EV charging cables offer a streamlined design option that ensures interoperability.

The GlobTek EV charging cables are a good example. These cables offer several features that make them attractive for non-EV applications:

- High current capacity for power levels up to hundreds of amperes (A) in both AC and DC configurations

- Rugged construction built to withstand extreme environmental conditions, including moisture, temperature fluctuations, and mechanical stress

- Standardized connectors compatible with globally recognized charging interfaces, ensuring seamless integration into various systems

These attributes make the cables an excellent fit for many medium-voltage applications with frequent connect/disconnect cycles. Prominent examples include EV-like applications such as electric forklifts and dockside power systems, where mobile systems must visit a charging port. The cables are also helpful for applications that call for temporary power infrastructure, such as outdoor events and disaster response units.

The cables can also be used for more permanent installations, simplifying integration. For example, they could be employed in robotics applications to provide a standardized connector that makes it easier to deploy automation equipment without needing unique power cables.

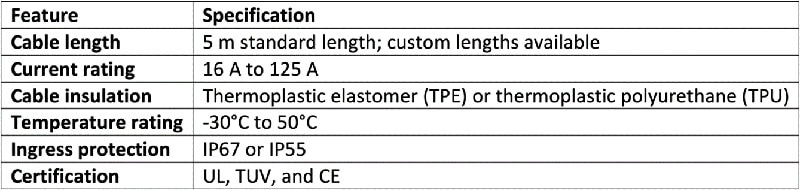

GlobTek charging cables are available in Type 1 (SAE J1722-2012), Type 2 (IEC62196-3:2014), and NACS (SAE J3400/UL2251) configurations, catering to a broad spectrum of applications and charging infrastructures. The cable specifications are shown in Table 1.

Table 1: The GlobTek EV charging cables offer appealing attributes for industrial environments. (Table source: Kenton Williston)

Table 1: The GlobTek EV charging cables offer appealing attributes for industrial environments. (Table source: Kenton Williston)

Cables for interoperable charge points

A typical example is the EVC250A040EA31B50002W (Figure 1). This 5 meter (m) cable features a Type 1 male plug on one end and four ring terminals on the other. It is rated for 250 volts AC (VAC) and 40 A, supporting high power delivery. With an IP55 rating and UL94V-0 flame resistance, it is ready for permanent installation in harsh environments. An insertion force of <100 newtons (N) and a rating of >10,000 insertions make it suitable for frequent connection cycling.

Figure 1: The EVC250A040EA31B50002W has a Type 1 male connector designed for permanent installations. (Image source: GlobTek)

Figure 1: The EVC250A040EA31B50002W has a Type 1 male connector designed for permanent installations. (Image source: GlobTek)

This cable can be used to create industrial charge points, providing an interoperable solution that solves a key pain point in industrial environments. Today, each type of electrified equipment might have its own charging infrastructure. For example, a forklift and pallet jack might have similar charging requirements but incompatible connectors. By moving to a standardized solution, different equipment could share a charge point, reducing the cost and complexity of transitioning to battery-powered equipment.

Detachable power cables

Another example is the EVE480A032UA28B5000FW shown in Figure 2. This 5 m cable features a Type 2 male plug on one end and a Type 2 female receptacle on the other. Its electrical specs are 480 VAC and 32 A, and the insertion force is between 50 and 100 N. Like the EVC250A040EA31B50002W, it has an IP55 and UL94V-0 rating.

Figure 2: The EVE480A032UA28B5000FW is a detachable Type 2 cable. (Image source: GlobTek)

Figure 2: The EVE480A032UA28B5000FW is a detachable Type 2 cable. (Image source: GlobTek)

This design can be used as an extension cable where the distance to the charging port varies. For example, it could accommodate ships of different sizes and configurations at a marine dockside. It is also helpful when a temporary connection is needed, such as at outdoor events.

Built-in power receptacles

GlobTek also offers receptacles that can be installed within an enclosure, such as inside a forklift or other heavy equipment. One such receptacle is the ESH1V0D350RA37A12001C (Figure 3). It features an NACS female plug on a faceplate, with 1 m cables leading to bare conductors. It is rated for 1 kilovolt (kV) and 350 A and can operate at temperatures of -30°C to 50°C.

Figure 3: The ESH1V0D350RA37A12001C is an NACS female receptacle that can be installed in heavy equipment. (Image source: GlobTek)

Figure 3: The ESH1V0D350RA37A12001C is an NACS female receptacle that can be installed in heavy equipment. (Image source: GlobTek)

These receptacles are well-suited for heavy-duty applications, including construction, mining, and agricultural machinery. Their high power rating makes them ideal for fast charging and powering high-demand equipment such as industrial robots and automated material handling systems.

Conclusion

GlobTek’s ruggedized EV charging cables and receptacles enable industrial and specialty applications to benefit from the EV market's innovation and cost-efficiencies. By leveraging advancements in EV charging technology, OEMs can incorporate standardized, high-performance power connectors into their industrial designs. This approach enhances flexibility, simplifies integration, and reduces reliance on proprietary power solutions.

Have questions or comments? Continue the conversation on TechForum, Digi-Key's online community and technical resource.

Visit TechForum

中国

中国