DigiKey电子元器件新产品信息 > New Energy – EV Charging

New Energy – Electric Vehicle Charging

TE Connectivity’s (TE) robust portfolio of EV charging products can help you address the challenges of designing and building the next generation of charging stations and EV charging infrastructure.

Charging your car at home or at work requires standard Alternative Current (AC) home charging units and workplace charging units. It is economic-effective and can be installed with great flexibility. While Direct Current (DC) charging stations relate to a very quick charging rate as little as 30 minutes. The rapid, global growth of electric vehicles requires the development of a charging infrastructure that is faster, safer, smaller and more flexible, which creates design challenges for engineers around the world.

As the world shifts to e-mobility and electric vehicles (EVs) specifically, there is an increasing demand for charging infrastructure, and it is becoming part of our daily life.

ICCON, Elcon Connectors

TE’s ICCON Power Connectors for Very High Current Density — Up to 200 Amps per inch that occupies less PCB edge space than separate ICCON power and guide modules. Designed to complement Z-PACK and other backplane connectors. Right angle connector to mate motherboard-to-daughterboard power distribution systems. Ground pin, power pin and mate-first-break-last pin options.

IHV Contactors

TE Connectivity’s IHV series contactors are used in high-voltage control and protection systems, charging stations, energy storage systems, and large-scale photovoltaic/energy storage inverters. With a current range of 50A to 350A and switching voltage up to 1800VDC, explore TE’s range of IHV contactors with DigiKey today.

Dynamic Mini Series Connectors

Dynamic Mini Series connectors are a high-performance choice for reliable signal and power transfer in battery management and energy storage systems. These connectors from TE offer a compact and reliable design for high retention force, and offer proven performance in harsh environments and vibration applications.

AMPMODU 2mm Connectors

TE’s AMPMODU 2mm connector system occupies 38% less space than traditional 2.54mm centerline products. Including breakaway headers, shrouded headers and board-mount and wire receptacles, these connectors support automated surface-mount, through-hole reflow, and traditional through-hole mount processes for ease of manufacturing.

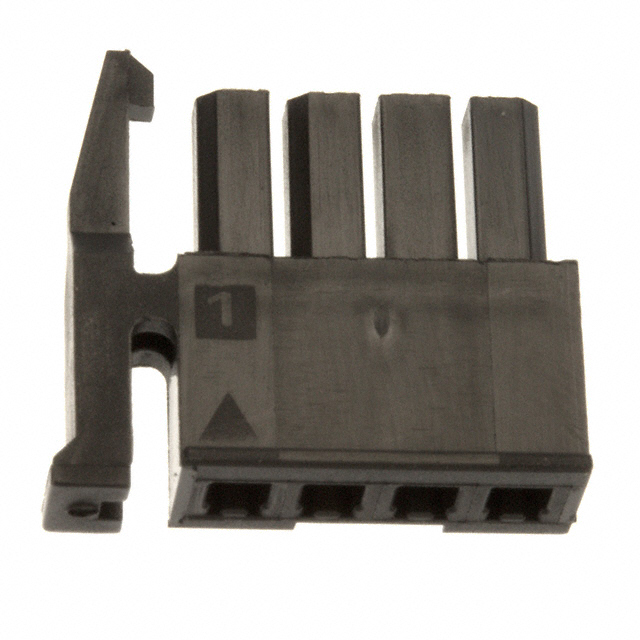

AMPMODU MTE Connectors

TE’s AMPMODU MTE interconnection system is utilized in wire-to-board and wire-to-wire applications, and can be found in many types of electronic equipment. They are available in IDC and crimp termination types while their latching capability provides positive retention between housings.

PIDG Terminals and Splices

PIDG terminals and splices (Pre-Insulated Diamond Grip) are designed for complete and uniform reliability in the difficult circuit environments. The design is vibration resistant and allows the wire to bend in any direction without damaging the wire insulation or conductor.

Identification Solutions

TE offers complete wiring identification and cable labels for a wide range of industries and applications. Designed for the most rigorous indoor or outdoor use, the portfolio of wire labeling and identification features flexible options including adhesive-backed wiring and cable labels, heat-shrinkable sleeves, cable markers, and hardware/software systems for onsite customization.

Heat Shrink Tubing

TE Connectivity (TE) heat shrink tubing provides electrical insulation, mechanical protection, environmental sealing, and strain relief for applications such as back-end connector sealing, breakouts, and connector-to-cable transitions. It is a solid alternative to taping, molding or potting. When heated, it conforms to the size and shape of the substrate beneath, enabling quick and easy installation.

EVSW Series

The Acceleration of Electric vehicles into the everyday lives continues to drive technology changes and challenges to maintain the optimum level of performance, reliability, and safety. Electric vehicles require components to operate at high temperatures and high voltage, not to propagate burning, and help the identification of circuitry. The new EVSW tubing from TE meets the unique challenges of EV applications, delivering a heat shrink tube specifically designed for use to insulate and protect conductive components and cables to ensure operational steadfastness and reliability.