Understanding the Chip Design Flow - Part 3 of our Verilog Journey

2024-02-22 | By DWARAKAN RAMANATHAN

What are ICs?

Integrated Circuits (ICs), also known as microchips or simply chips, are miniaturized electronic circuits that consist of a large number of electronic components, such as transistors, resistors, capacitors, and interconnections, all fabricated on a tiny semiconductor wafer or substrate. These components work together to perform various functions, from simple logic gates to complex microprocessors. ICs have revolutionized the electronics industry by enabling the development of smaller, more efficient, and cost-effective electronic devices. There are several types of ICs, including:

- Analog Integrated Circuits (Analog ICs):

- Analog ICs are designed to process continuous signals, such as audio, voltage, or current, where the signal values can vary continuously.

- Types of analog ICs include operational amplifiers (op-amps), voltage regulators, analog-to-digital converters (ADCs), and analog filters.

- Digital Integrated Circuits (Digital ICs):

- Digital ICs are designed to process digital signals, which have discrete, binary values (0s and 1s.)

- Types of digital ICs include microcontrollers, microprocessors, memory chips (RAM and ROM), digital signal processors (DSPs), and field-programmable gate arrays (FPGAs).

- Mixed-Signal Integrated Circuits:

- Mixed-signal ICs combine both analog and digital circuitry on a single chip. They are commonly used in applications where analog and digital signals need to be processed together.

- Examples include analog-to-digital converters (ADCs) integrated with microcontrollers and mixed-signal ASICs (Application-Specific Integrated Circuits.)

- Radio-Frequency Integrated Circuits (RFICs):

- RFICs are specialized ICs designed for radio-frequency applications, such as wireless communication, radio broadcasting, and radar systems.

- Types of RFICs include RF amplifiers, RF mixers, and RF transceivers.

- Power Integrated Circuits (Power ICs):

- Power ICs are tailored for power management and control tasks, including voltage regulation, power conversion, and energy harvesting.

- Examples include voltage regulators, power amplifiers, and DC-DC converters.

- Memory Integrated Circuits:

- Memory ICs are used for data storage and retrieval. They come in various forms, including volatile (temporary) and non-volatile (permanent) memory.

- Types of memory ICs include DRAM (Dynamic Random-Access Memory), SRAM (Static Random-Access Memory), NAND flash, NOR flash, and EEPROM (Electrically Erasable Programmable Read-Only Memory.)

- Application-Specific Integrated Circuits (ASICs):

- ASICs are custom-designed ICs for specific applications. They are optimized for a particular function or set of functions, making them highly efficient but less flexible.

- Examples include ASICs used in automotive control systems, medical devices, and industrial automation.

- System-on-Chip (SoC):

- SoCs integrate multiple functions, including processing units, memory, communication interfaces, and more, into a single chip. They are often found in smartphones, IoT devices, and embedded systems.

- Digital Signal Processors (DSPs):

- DSP ICs are specialized for processing digital signals, making them ideal for tasks like audio processing, image processing, and communications.

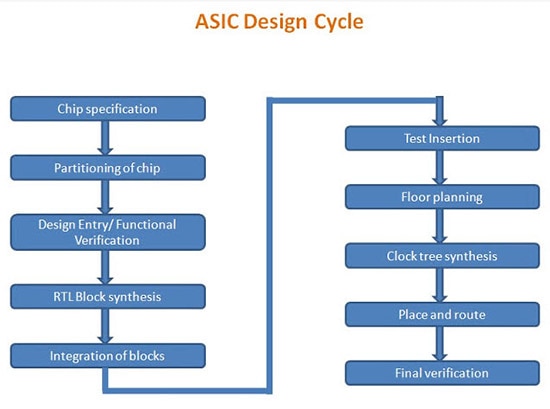

Chip Design Flow:

The chip design flow, also known as the VLSI (Very Large-Scale Integration) design flow, is a systematic process that engineers follow to design and manufacture integrated circuits (ICs) or chips. This process involves a series of steps from concept to the physical implementation of the chip.

- Specification and Requirement Analysis:

- In this initial phase, engineers define the purpose and functionality of the chip. They gather requirements, including performance, power consumption, and size constraints, to guide the design process. Clear specifications are crucial for a successful chip design.

- Architecture Design:

- Engineers create a high-level architectural blueprint of the chip. This includes defining major functional blocks, their interconnections, and overall system organization. The goal is to establish a clear structure for the chip's logic.

- RTL Design (Register-Transfer Level):

- At this stage, designers use a hardware description language (HDL) like Verilog or VHDL to describe the chip's logic and behavior at a register-transfer level. They specify how data is transferred between registers and processed, including logic gates and data paths.

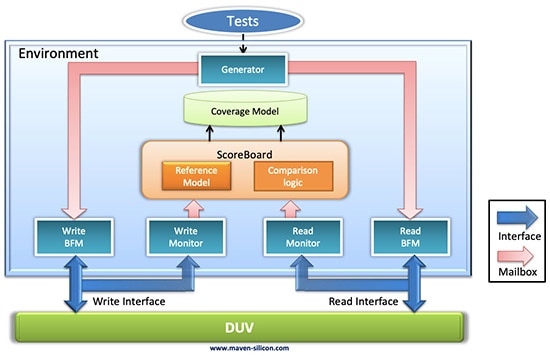

- Functional Verification:

- The RTL design undergoes rigorous testing through simulation and verification. Engineers create test benches and run test cases to ensure that the chip behaves as intended. Verification identifies and corrects design errors.

- Synthesis:

- The RTL code is synthesized into a gate-level netlist. This step transforms the high-level RTL description into a detailed representation of logic gates and flip-flops that will implement the design.

- Physical Design:

- Physical design involves floor planning, where designers determine where to place different components on the chip. They also plan routing paths for interconnections, considering factors like signal timing and power consumption.

- Timing Closure:

- Timing analysis is performed to ensure that the chip meets critical timing requirements. Designers may optimize logic paths and adjust clock frequencies to achieve timing closure. Timing issues can impact chip performance.

- Design for Testability (DFT):

- DFT techniques are employed to make the chip testable during manufacturing. This includes adding test circuitry, such as scan chains, which allows for efficient testing of the chip's functionality and identifying any defects.

- Physical Verification:

- Before manufacturing, engineers conduct physical verification to check for design rule violations, manufacturing defects, and electrical issues in the chip's layout. Ensuring the layout is manufacturable is essential.

- Simulation and Emulation:

- Additional simulation and emulation are performed to thoroughly validate the chip's functionality and performance. This may include running extensive test suites to mimic real-world usage.

- Mask Generation:

- The final chip layout is used to create photomask sets. Masks are critical in the semiconductor manufacturing process, guiding the patterning of the integrated circuits onto silicon wafers.

- Fabrication (Manufacturing):

- The chip is fabricated in a specialized semiconductor manufacturing facility (foundry). This involves processes like photolithography, etching, doping, and more to create the physical chip.

- Assembly and Packaging:

- Once individual chips are fabricated, they are assembled into packages that include pins or pads for connecting to external circuits. Packaging protects the chip and facilitates integration.

- Testing:

- Chips undergo comprehensive testing to verify that they meet their specified functionality and quality standards. Testing includes functional testing, performance testing, and manufacturing testing to identify defective chips.

- Quality Assurance and Yield Enhancement:

- Measures are taken to improve chip yield, ensuring a higher percentage of working chips per wafer. Quality control processes are implemented to maintain consistency.

- Final Product Integration:

- The chips are integrated into end products, such as smartphones, computers, IoT devices, or other electronic systems, where they perform their intended functions.

Conclusion:

In summary, the chip design flow in VLSI (Very Large-Scale Integration) is a meticulously structured process that transforms abstract concepts into integrated circuits (ICs) powering our modern devices. It encompasses defining specifications, designing logic, rigorous testing, manufacturing, and integration. The precision and expertise involved in each step of this journey drive technological innovation, ensuring that ICs meet the demands for faster, smarter, and more efficient electronic devices. The chip design flow remains a cornerstone of the ever-evolving world of semiconductor technology, shaping our technological future and enhancing our daily lives.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum

中国

中国