培植肉技术和效率

对于工厂化养殖的反对者或单纯的美食追求者来说,现在还要面对正在进入市场的培植(实验室培育)制品。与植物肉和来自蘑菇的菌蛋白一样,生产这些食品的碳排放低于传统肉类,尤其是牛肉。

具体来说,据估计,与传统肉类生产相比,培植肉可至少减少 80% 的用水和 90% 的用地。若将副产品和废料(如废生物质)的处置计算在内,总体碳排放的计算结果会有一些变化。

除了 Believer Meats、Ever After Foods 和 Upside Foods 等少数几家公司之外,这些潜在产品大都仍处于研发阶段。尽管如此,过程自动化和离散自动化技术正在用于帮助找出和扩展生产这些培植肉的最佳方法。

毫无疑问,一旦行业发展起来,这种自动化技术将成为这些肉类大规模生产和满足食品安全监管要求的核心。

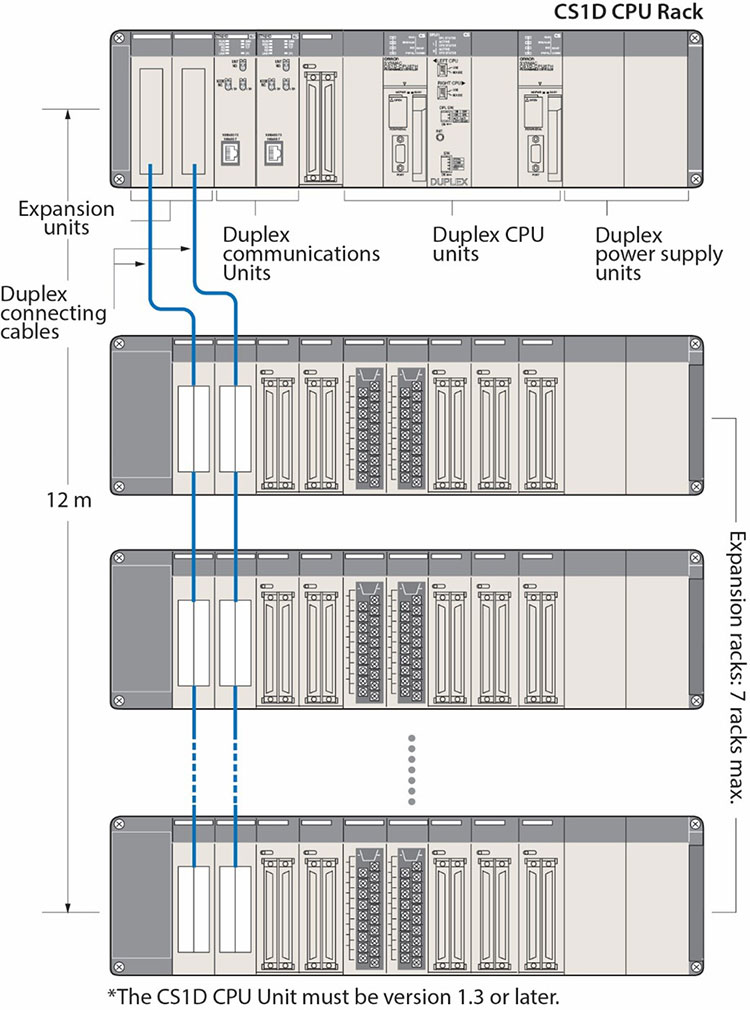

图 1:PLC 和 PAC 控制系统很快就能控制培植肉生产的过程和离散自动化,生产出具有牛肉、鸡肉和其他肉类的外观、质地和味道的培植肉。(图片来源:Omron Automation and Safety)

图 1:PLC 和 PAC 控制系统很快就能控制培植肉生产的过程和离散自动化,生产出具有牛肉、鸡肉和其他肉类的外观、质地和味道的培植肉。(图片来源:Omron Automation and Safety)

尽管具体做法各有不同,但通常都是从供体动物身上提取细胞并暂时储存。然后将这些细胞放入生物反应器(类似于啤酒或疫苗生产中使用的生物反应器)中,加入植物或明胶支架、营养物质和细胞分化培养基(促使细胞分化成肌肉或脂肪形态),让它们生长。在几周的时间里,自动化系统严格控制生物反应器的内部温度、pH 值、营养投入和氧气水平,以优化细胞的生长。

图 2:这种生物反应器采用气动搅拌技术和软件,利用通过数字孪生模型获得的优化来改进现有技术。(图片来源:Arc Biotech)

图 2:这种生物反应器采用气动搅拌技术和软件,利用通过数字孪生模型获得的优化来改进现有技术。(图片来源:Arc Biotech)

为确保食品安全,生产中使用的大型自动化组件必须能够耐受就地清洁和就地灭菌过程。因此,与其他食品生产设备一样,主要采用不锈钢外罩、外壳和容器。除了与食品直接接触的机器金属部分需要采用不锈钢外,不锈钢还能帮助这些设备经受住经常暴露于化学品、高热、冲洗用水以及灭菌蒸汽的考验。

图 3:304 不锈钢气缸和 303 不锈钢活塞杆有助于气缸耐受食品加工设备所需面对的恶劣条件。(图片来源:Fabco Air)

图 3:304 不锈钢气缸和 303 不锈钢活塞杆有助于气缸耐受食品加工设备所需面对的恶劣条件。(图片来源:Fabco Air)

培植肉产业的关键要素还包括:

• 通过物联网传感器、I/O 和数据采集设备对生物过程进行实时监控——其形式越来越多地是将设备集成到采用数字化转型 (DX) 架构的云系统中

• 机器人(有时辅以人工智能图像识别技术),用于各种细胞分选、种植、采样、收获和质量控制任务

• D 打印设备,通过挤制混合成分来复制特定肉块的成分和质地

当然,其他类型的食品生产(如果树种植)使用自动化的程度也在不断提高。加工和包装设施,以及田地、果园,甚至温室和垂直种植作业中都有这种设备的身影。在当今自动化机械所带来的众多好处中,最重要的可能是其轻柔处理易碎果蔬的能力。在某些情况下,将易碎果蔬运往市场的机械化效率与运送不易碰伤或损坏的谷物、豆类和其他行栽作物相同。

这不禁令人思考:既然果蔬对健康有很大的好处,而且花费远低于培植肉甚至传统肉类生产,也许我们都应该时常多吃些蔬果。

Have questions or comments? Continue the conversation on TechForum, Digi-Key's online community and technical resource.

Visit TechForum