How to Select the Right DC/DC LED Driver

投稿人:电子产品

2015-09-29

Designing the most optimal DC/DC LED driver can boost the dimming performance, color rendering, and consistency of a range of indoor and outdoor lighting applications, addressing some of the challenges associated with color and brightness control.

Most LED driver vendors agree that once the LED is selected there are four key specifications that LED lighting designers need to know—input voltage range, output voltage of the LED string, current, and dimming option—in order to narrow down the list of optimal LED drivers for the application.

Other areas that need to be looked at include dimming performance, color rendering index (CRI), and efficiency. Color brightness and rendering true color may be more important for retail lighting, for example; and color consistency is often a priority in high-end applications where a number of the same fixtures are used.

At the same time, lighting designers have to keep in mind several potential design constraints—cost, size, and thermal issues—depending on their application. For example, in high-performance, high-end applications, cost constraints will likely not be an issue. So again, keep in mind the end applications when determining the right LED driver for the job.

In addition, a lighting designer’s knowledge of power systems will come into play in the selection. Many LED vendors offer a driver portfolio that ranges from those that are simple to use, relatively speaking, to more complex devices that are packed with features and functionality that can be used by power experts. They also offer a slew of design tools and calculators for driver selection.

So where do you start? Once the system specs are known, including lumens per watt required for the system and lumens per watt of the LED, designers need to know the input voltage range, output voltage (the full min/max of the LED string), LED string current, and how to dim it; PWM or ratio.

John Perry, marketing manager, Texas Instruments, Lighting Power Products, shared some of the key questions that he initially asks a lighting designer before making a driver solution recommendation:

- What is the input supply voltage range to the LED drive circuit? Examples: 48 VDC, 60 VDC, 120 VAC

- What is the LED load configuration and characteristics (series, parallel, series-parallel)? What is the min/max LED string voltage? What is the desired maximum LED drive current?)

- Is dimming required? If so, by what means: analog, PWM, combination, other?

- What (if any) are the fault detection, protection, and reporting requirements?

The goal is to match the customer’s need with the best driver solution. Other considerations include design constraints around cost, size, heat, and efficiency. In terms of size, one of the things that designers can look at are LED drivers with integrated MOSFETs if they are dealing with a low-power system. This also can be a cost saver.

“When you integrate MOSFETs there is a power maximum. As long as your specs are not exceeding that power limitation you’re pretty good,” said Brandon Cartwright, regional segment marketing manager, Lighting, Infineon Technologies North America. “However, the one thing you can’t control is what that MOSFET is on the inside. You have more flexibility with an external MOSFET so you can scale it for higher power and usually get better efficiency.”

Whenever possible, Linear Technology recommends a monolithic device where the power device is internal. This typically means two less components the lighting designer needs to choose, said Bryan Legates, Linear Technology’s design manager for LED driver products.

“If you have ever tried to search for power MOSFETs, it’s overwhelming, so if the power level is low enough we always suggest they first try the design with a monolithic device. But at higher power levels at 50, 60, or 100 watts, and even up to 200 or 300 watts you end up having to choose external FETs because you can’t do that kind of power on the same IC. You have to spread the heat out,” added Legates.

Another way to reduce costs sometimes requires a simple change in the design, said Legates. “If they are willing to make simple changes such as reducing the design by one LED, adding an LED or changing the current, they actually get a much more cost-effective solution.”

He explained: “Keep in mind that many customers want to do a 24 volt input and 24 volts for the LED output. If you want the input and output the same it guarantees that you’ll be using the most expensive DC-to-DC converter. Once they start down that path we ask them if they are willing to make some small changes in their LED string and many times they are, which results in saving a dollar or two on all components.”

Most LED-driver manufacturers are trying to make it easier for lighting designers, who often have to deal with the whole system box design. Historically, lighting has been focused on the mechanical aspects—how does the light look visually and architecturally, said Legates. “They literally just plugged a bulb in and now they are being asked to understand DC-to-DC converters, EMI and PCB boards, all these things they’ve never dealt with. So for many of them it’s very much out of their element so that is where service and expertise come in.”

One example of a device that is easy to design with is Infineon’s ILD6070 DC/DC LED driver with flexible dimming options. The datasheet provides a table guideline to select the right inductor and resistor to use with the device. In addition, it’s very scalable and can handle one to eighteen LEDs in series. It also offers very high efficiency of 98 percent and is a small-size solution thanks to its higher frequency operation, which enables the use of a smaller inductor. It also features a high-output current accuracy of +/- 3 percent, and up to a 3000:1 contrast ratio.

Another key feature of the ILD6070 is its advanced thermal control. It has a very easily settable over-temperature protection via one resistor, said Cartwright. The thermal control allows for a reduction of light output instead of shutting down the whole system so it protects the system while keeping the light on. Of course, if it continues to get hotter, it will shut down based on the temperature profile programmed with the resistor.

Many vendors use an in-chip thermal control but they are doing a simple shutdown, said Cartwright. “If it gets too hot it shuts off.”

Some chips reduce the light but they have to do it with an external thermistor or NTC, he added. In comparison, the ILD6070 has an internal NTC so it does not add external costs and it keeps the solution size small.

A sister device to the ILD6070 is the ILD6150 switch-mode DC/DC LED driver. The ILD6150 and the ILD6070 are basically the same part with the exception of the output current. The 6150 offers one and a half amps output max and the 6070 offers 700 mA max so it will be a little cheaper, said Cartwright. Evaluation boards are available for the ILD6150 (EVALLED-ILD6150, Figure 1) and ILD6070 (EVALLED-ILD6070).

Figure 1: The demo board for Infineon’s 60 V LED Driver ILD6150 is available for evaluation. The ILD6150 features high-output current accuracy of +/- 3 percent for improved color consistency. (Courtesy of Infineon)

Dimming and color control

Dimming performance is becoming more and more critical as LEDs are being held to a higher standard than traditional fluorescent and HID solutions, and is a concern for most lighting designers, said Infineon’s Cartwright.

“We also are getting a lot of requests for color control, which means tunable light and sometimes 3- or 4-channel control. Microcontrollers here are a big play along with the precision of the driver because the light is directly correlated to the current going through the LED. So tight regulation on the current is very important,” Cartwright said.

“For color control or accuracy, if people are mixing cool and warm LEDs, for example, to give the user an adjustable color temperature, the performance of the driver’s output is very critical. To get that exact lumens output for each color, you’d typically employ a microcontroller (MCU) and the MCU can also do a DC-to-DC power conversion as well as any communications that is needed,” he said.

Infineon’s XMC1200 eval kit, for example, was developed specifically for LED lighting. The company’s plug-and-play DAVE tool, a free development platform for code generation, will do all the calculations required for the design. Infineon recommends this ARM-based MCU for most low-cost, entry-level lighting applications that need color mixing.

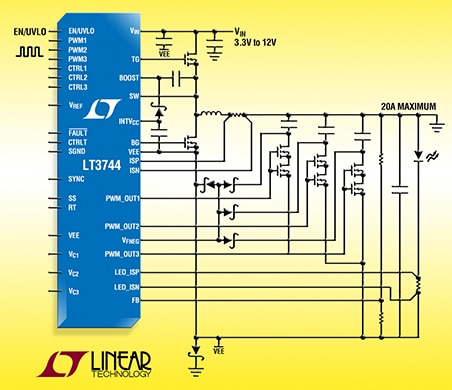

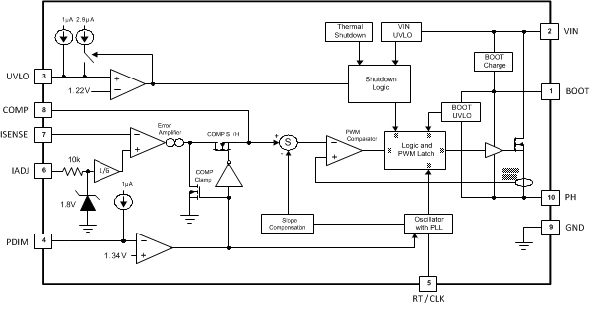

For high-end applications, Linear’s LT3744 step-down LED driver (its predecessor is the LT3743) offers 0 to 100 percent dimming and three on-states, plus an off-state, for better color mixing to achieve a true color (Figure 2). Linear’s Legates said the biggest advantage of that is for high-end applications that need true color representation, but he noted that it does require a lot of calibration.

Figure 2: The Linear Technology LT3744 step-down LED driver offers 4-state control for color-mixing applications. It also offers a fast transition between two regulated LED currents in less than 2 µsec, enabling more accurate color mixing in RGB applications. (Courtesy of Linear Technology)

Other key features include up to 3000:1 PWM dimming, 20:1 analog dimming, voltage and current regulation accuracy of +/-3 percent, and a 3.3 V to 36 V input voltage range. The LT3744 can drive up to 40 A LEDs.

“If you do PWM dimming wrong, it can change the color of the LED as you dim from 0 up to 100 percent,” said Legates. “The way the LED is dimmed does effect the color of the LED and quality of the light out of the LED. With LED drivers, we always think about perception and visible light. They don’t want to see flicker. If you have a dozen of these in a row, you would prefer that they all look the same. One of the challenges is making everything repeatable and everything consistent in light color and brightness.”

Texas Instruments uses a different dimming approach with its TPS92512 LED driver (Figure 3). It features two separate control pins for dimming (PWM and analog). “When you have independent control you have a lot of flexibility, in terms of the total contrast and light output you can achieve from max brightness virtually down to zero. The number of steps in between are greater,” said TI’s Perry.

Figure 3: Texas Instruments’ TPS92512 LED driver with an integrated MOSFET offers two inputs—analog and PWM dimming—for complete dimming flexibility. The analog adjust can be used for calibration and/or thermal foldback protection. (Courtesy of Texas Instruments)

“If on average a good performance buck LED driver can do 500:1 dimming ratio via PWM, and with analog dimming you get 10:1 to 20:1, it becomes a multiplier with the options to use both of those controls. So, if you had 500:1 and 10:1, you can achieve a 5000:1 contrast ratio if you’re able to use those,” Perry explained.

In addition to the PWM and analog dimming, key specs of the TPS92512 include up to 95 percent conversion efficiency, max output current accuracy of +/- 5 percent across all operating temperatures, and an integrated 200 milliohm high-side MOSFET. The input-voltage range is 4.5 to 42 volts and the switching-frequency range is 100 kHz to 2 MHz. An evaluation board for the TPS92512 is also available.

Summary

Lighting designers need to know four key specs before they think about selecting a driver, always keeping in mind their expertise and knowledge in power design, which can influence the driver selection, depending on features and functionality. These specs are input-voltage range, output voltage of the LED string, current, and dimming option. However, they also need to consider other factors such as dimming performance, color control and consistency, and efficiency. At the same time, they need to balance several potential design constraints—cost, size, and thermal issues—depending on their application.

For more information about the parts discussed in this article, use the links provided to access product pages on the DigiKey website.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国