Charging Lithium-Ion and LiPo Batteries the Right Way

2021-10-13 | By Maker.io Staff

The first article in this series investigated common secondary battery types and their pros and cons in different settings and applications. The second article looked at battery management systems and what tasks they have to fulfill to ensure the safe and efficient operation of rechargeable Lithium batteries. This third part of the series introduces how to correctly charge Lithium-Ion and LiPo batteries so that you can understand what you need to do when implementing a custom charging circuit.

Charging a Lithium Cell

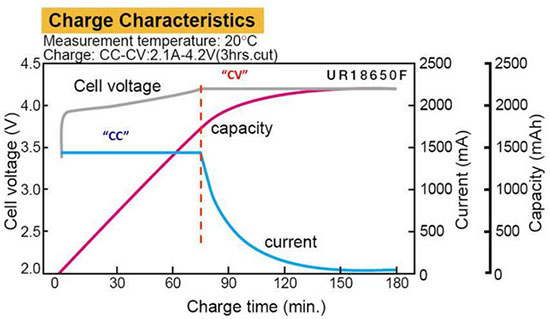

Typically, you charge lithium batteries by applying the CC-CV scheme. CC-CV stands for Constant Current - Constant Voltage. It denotes a charging curve where the maximum allowed charging current is applied to the battery as long as the cell voltage is below its maximum value, for example, 4.2 Volts. Once the battery reaches that voltage level, the charge controller gradually decreases the current to hold the battery at a constant voltage of 4.2 Volts:

Ideal charge characteristics. The current remains constant until the battery reaches its maximum voltage. Then, the controller gradually reduces the current to keep the voltage of the cell constant.

Source: https://www.digikey.at/de/ptm/t/texas-instruments/introduction-to-battery-management-part-3/tutorial

Ideal charge characteristics. The current remains constant until the battery reaches its maximum voltage. Then, the controller gradually reduces the current to keep the voltage of the cell constant.

Source: https://www.digikey.at/de/ptm/t/texas-instruments/introduction-to-battery-management-part-3/tutorial

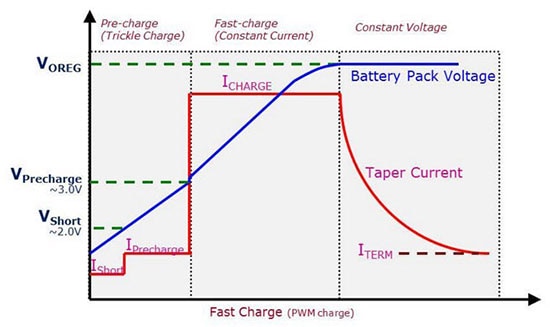

In reality, this scheme is often not applicable, and sometimes it might even be unsafe. Therefore, a more realistic charging scheme splits the charging process into multiple segments. First, it depends on the cell voltage where the more sophisticated process starts. If the cell voltage is very low, charging starts with a small current to revive a possibly dead cell. This method is also safer, as charging a damaged cell too quickly could lead to a potentially catastrophic failure, such as a battery fire.

Once the cell reaches a certain safety threshold, for example, 3.0 volts, the charging process continues by constantly applying the maximum charge current until the cell voltage reaches the maximum allowed value (e.g., 4.2V). After that, the charger gradually decreases the current while constantly holding the battery at its maximum voltage level:

A realistic charge scenario. The process starts with a lower current before the charger puts the maximum defined current into the cell. Source: https://www.digikey.at/de/ptm/t/texas-instruments/introduction-to-battery-management-part-3/tutorial

A realistic charge scenario. The process starts with a lower current before the charger puts the maximum defined current into the cell. Source: https://www.digikey.at/de/ptm/t/texas-instruments/introduction-to-battery-management-part-3/tutorial

To further increase the safety of the process, each step in the charging scheme typically also has a time limit associated with it. An additional temperature cut-out switch prevents the battery from overheating.

Considerations for Designing a Custom Battery Charger

Luckily, makers don’t have to worry too much about the exact details of how to safely charge and discharge a Lithium-Ion or LiPo battery pack in their projects. Since battery-operated portable devices are so common in our modern world, all the safety features and correct charging algorithms are already widely implemented in various readily available components you can buy and use in your projects today. Regardless, you’ll still need to think about a few key numbers and limitations relevant to your battery and exact use case.

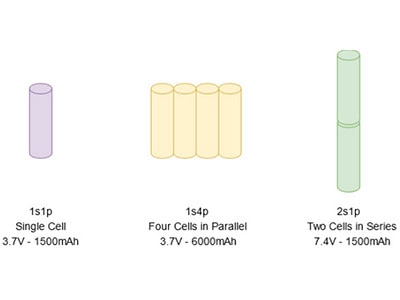

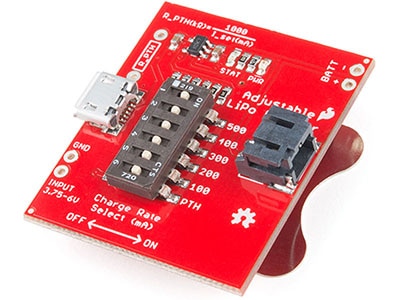

When designing a single-cell Lithium-Ion charger, record the allowed maximum charge current and voltage of the battery in use. Then determine the voltage and maximum charge current of the power supply you want to use for charging. Usually, this will be five volts and between 500 mA and 900 mA (USB 2.0 and USB 3.0).

Next, think about the type of charger you want to use. Linear chargers are typically low-current chargers intended for currents below one ampere. These chargers are cost-effective, small, and simple to use. Switch-mode chargers are more costly but also more efficient than linear chargers. You should use a switch-mode charger if you plan on utilizing fast charging with currents above one ampere. Regardless of the type of charger, both options come pre-implemented by a large variety of PMICs (power-management ICs) from various manufacturers.

Once you’ve decided what the maximum charge current will be, think about whether you want the user to be able to work with the device while it charges. While it’s possible to implement an in-line charging functionality externally, it’s best to look for a charging IC that already supports it. Doing so will guarantee maximum safety and efficiency because the IC can monitor the current going into the battery more accurately and disconnect the battery in case of a fault condition.

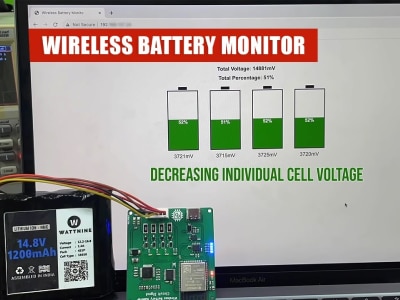

Lastly, some ICs allow you to easily set essential parameters such as the maximum constant charging current, voltage thresholds, timing constraints, and the cut-out temperature by adding appropriate resistors or applying logic-level inputs to certain pins. Other ICs might require an additional microcontroller to change the settings via I2C, for example. The first option is typically cheaper and easier to implement, while the latter offers more flexibility and better monitoring.

Luckily, there is a ready-made chip for almost all applications you can think of, regardless of the method you choose and the specifications of your project.

Summary

Typically, PMICs charge LiPo and Lithium-Ion batteries using the CC-CV method. The battery gets charged with a constant current until the cell reaches its maximum voltage. From then on, the charger gradually decreases the charge current until the battery is fully charged. Modern charge ICs apply a few more steps to the process to increase safety. These ICs monitor the cell temperature and have a programmable cut-out function that stops charging the cell after a pre-set period.

When designing a charger, note the cell voltage, maximum charge current, and capacity. Then, think about the power supply limitations and whether you want to use a linear or switch-mode charger. Linear chargers are typically more cost-effective and smaller, which makes them ideal for simple circuits and a charge current of less than one ampere. Switch-mode chargers are more efficient and ideal for fast charging.

Many charge ICs allow you to set vital parameters using resistors or logic-level inputs. Some ICs, on the other hand, might require a host, such as a microcontroller, to configure values such as the cut-out temperature.