Harness 3D Calibration Prints to Improve Print Quality

2024-06-12 | By Maker.io Staff

Calibration prints are paramount to ensure the accuracy, reliability, and quality of prints produced by a 3D printer. You can choose from many different test prints, and this article outlines some essential types of calibration prints, what they tell you about your printers, and how to overcome problems uncovered by the individual tests.

Improving Surface Finish

Imperfect surface finish is amongst the most common problems in 3D printing. Incorrectly calibrated 3D printers can lead to various surface finish problems in both the vertical and horizontal axes.

Vertical surface finish problems include artifacts such as ringing, layer lines, or z-axis banding. In more general terms, the printed part’s vertical surfaces exhibit some defects that can be purely cosmetic but also lead to layer adhesion problems. Horizontal surface finish problems include holes and other imperfections in surfaces parallel to the print bed.

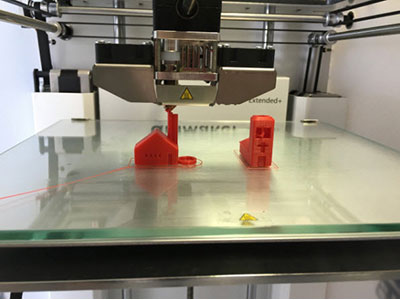

You can print a so-called calibration tower, a thin quadratic tube to assess your printer’s capability to produce a satisfactory vertical surface finish. Ensuring sufficient tower height is essential, as some problems only occur beyond a certain height.

Once the printer is done and the part cools down, you should inspect the tube’s walls for potential defects, such as misaligned or shifted layers or holes in the surface. If the vertical surface exhibits noticeable defects, it may indicate issues with z-axis alignment, inconsistent extrusion, insufficient cooling, or improper slicer settings. In those cases, you should adjust the printer’s z-axis alignment and clean the extruder. Optimizing slicer settings such as the cooling, layer height, and printing speed can also help.

Image courtesy of Thingiverse.

Image courtesy of Thingiverse.

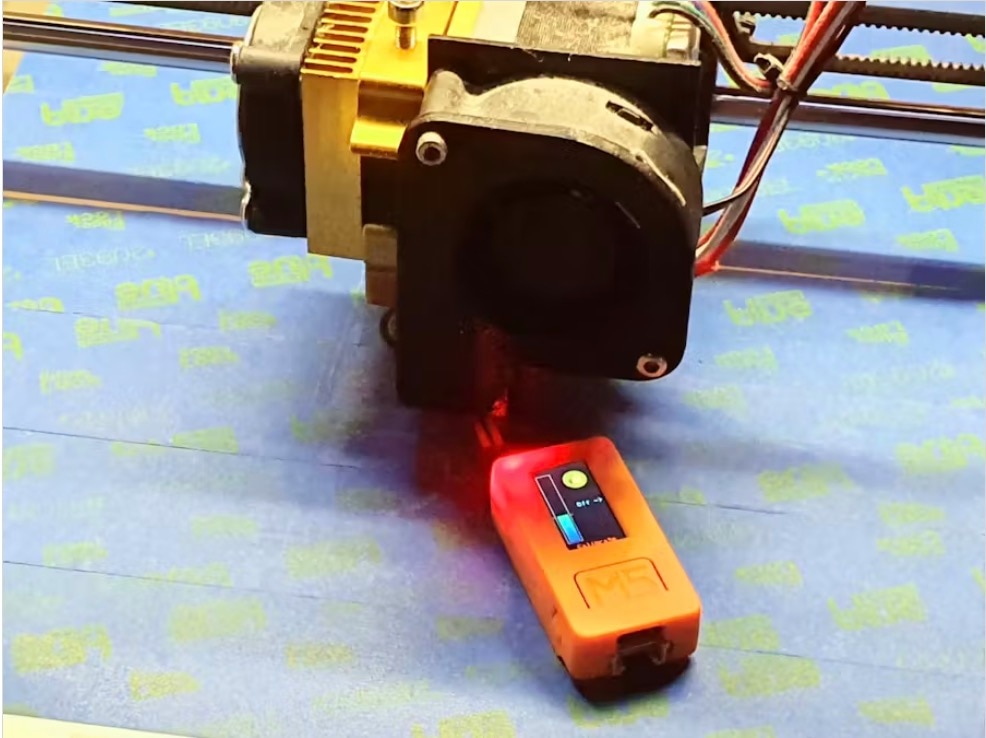

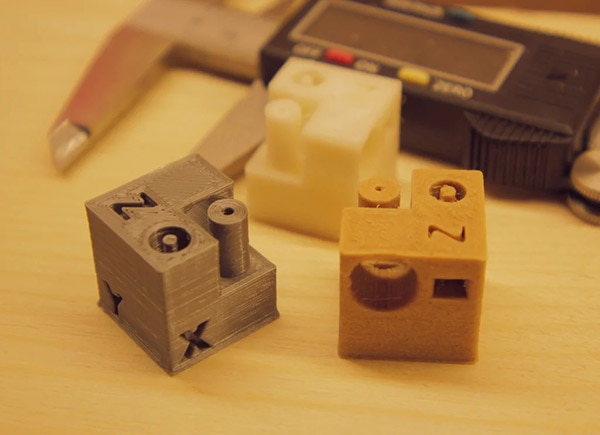

Test cubes are often used to verify the dimensional accuracy of a 3D printer. However, they can also help uncover surface finish problems, as shown in this image. The top surface contains holes, which may hint toward an insufficient flow rate.

Large, flat surfaces can help you identify horizontal surface finish issues. Poor horizontal surface quality can stem from inadequate bed adhesion, insufficient cooling, improper temperature settings, or inadequate infill density. In those cases, you should improve bed adhesion through proper leveling and surface preparation and ensure adequate infill density to support the top layers. Lowering the print speed and tweaking the temperature can also help improve results.

Dimensional Accuracy Tests

Multi-part and functional prints require high dimensional accuracy to ensure that parts fit together. To ensure your device is well calibrated, you can print dimensional accuracy calibration parts with a fixed, known size and measure how using different printer or slicer settings affects the part.

Test cubes are a de facto standard for determining outside dimensional accuracy. In this test, you create a fixed-size cube, print it, and measure the finished cube’s dimensions to determine the deviation from the expected width, height, and depth. Then, you tweak settings without altering the cube’s dimension and observe how the changes affect the result.

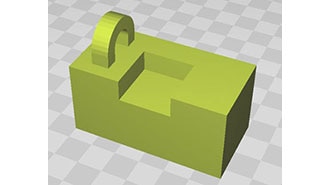

Negative space tests are a way of determining a printer’s accuracy when printing inner diameters, such as screw holes or cavities. Accurate holes, bores, and cavities are vital in multi-part prints to ensure the components fit together.

Image courtesy of Thingiverse

Image courtesy of Thingiverse

Calibration objects with small inner and outer diameters are perfect for assessing a printer’s dimensional accuracy.

Regardless of the exact test piece or method, you must remember that many external factors influence dimensional accuracy tests. You must repeat the calibration process whenever you swap materials, as material shrinkage, for example, also affects dimensional accuracy. Therefore, you shouldn’t spend too much time and effort on these tests. Instead, you should use them to get the ratios and accuracy to be in a tolerable range.

Calibration Prints for Better Overhangs and Bridges

These tests evaluate the printer’s capability to produce accurate overhang areas and bridges without further support structures. Both assess the printer’s and slicer software’s cooling settings and filament flow control.

A Successful test results in accurate overhang and solid, structurally sound bridges in the printed calibration piece. Sloppy overhangs or drooping bridges indicate problems that you can overcome by tweaking the fan speed, print temperature, and print speed. Typically, reducing the temperature and increasing the bridging speed helps build better bridges, as the filament will have less time to sag and cool down more quickly, leading to faster solidification and more accurate bridges.

Uncover Slicer Accuracy Problems

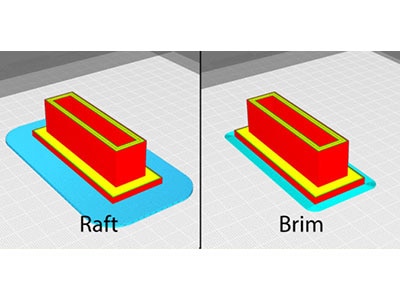

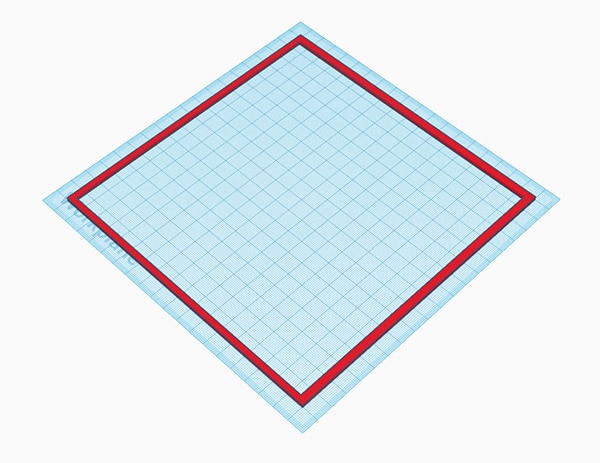

The final category summarizes tests that determine how accurately the slicer software is tuned to the printer’s physical properties. The full-bed size test prints a thin but large part that outlines the entire printable area. This test helps you calibrate the printer’s origin point and bed size in the slicer software, as misaligned values lead to the printer traveling beyond the bed or failing to print the part in its entirety due to it extending over the printable area.

A large, thin object can help you detect placement issues.

A large, thin object can help you detect placement issues.

Retraction and travel tests help identify problems such as dripping, stringing, and clogging. Adjusting the retraction amount and altering the extrusion modifier can help. However, too much retraction can lead to heat creep and cause clogging.

Similar to the previously described dimensional accuracy tests, the results and adjustments depend heavily on the material and environmental factors, such as humidity and temperature. Therefore, it’s best to calibrate this setting only when problems, such as excessive stringing between parts, occur during regular operation.

Summary

Calibration prints are vital for ensuring the accuracy, reliability, and quality of parts produced by a 3D printer. The most common calibration prints help improve surface finish, dimensional accuracy, overhangs, bridges, and slicer accuracy by identifying the potential root cause of these problems, including inconsistent extrusion, insufficient cooling, improper slicer settings, or inadequate bed adhesion.

While you can use calibration prints to adjust your printer's settings and improve print quality, you should remember that many external factors influence print quality. Some tests need to be repeated when swapping materials. Therefore, it’s best to use these tests to get the printer to produce parts within reasonable tolerance levels.