UV Sources Shine on More Applications

投稿人:电子产品

2011-11-01

Ultraviolet (UV) light plays a more important part of our daily lives than most people realize. Every time you use a bank machine or a vending machine accepting bills chances are a buried UV light source is checking the currency to detect a possible counterfeit note. When you dry your hands with electric hot air dryers, there is often a buried UV light source embedded in the machine to kill bacteria. Chances are also better than good that your local dentist is using UV light inside a patient’s mouth to catalyze coatings or bonding agents for caps, bridges, and braces.

Biohazard detection technologies use ultraviolet light sources, too. Couple this with the increasing need for UV illuminators in the medical research and biological fields and it becomes readily apparent that UV light source design may soon be a part of a lighting engineer’s project portfolio.

Advancements in UV source emitters, coupled with semiconductor technology, have extended the spectral capabilities of UV light sources. As a result, engineers will find a wide selection of products at specific wavelengths readily available at reasonable prices.

This article describes the UV light source technologies available today. It discusses their features and benefits, and applications that could be taking advantage of these technologies. All parts discussed here are available on the DigiKey website.

UV tubes

Traditional UV lamps consist of glass tubes based on Mercury technology. Many are still in use and there are times where tube lamps have distinct advantages; CCFL technologies for backlighting and UV light source bulbs are proving to be environmentally friendly and remain cost-effective illuminators for many UV designs.

A key benefit of tubes is that they can easily and directly illuminate a large swath or area. Straight in-line tubes can be made in varying lengths and diameters providing a control mechanism to light specific areas with specific intensities from a single unified source. A motorized transit for dollar bills, for example, can use the UV source to test the proper fluorescent level, as well as illuminate high-contrast areas that will be digitally scanned and recognized.

Tubes can be made in a zigzag pattern as well. This allows them to cover large areas rather uniformly with minimal use of diffusers and intensity gradient films. Tubes also have good spectral qualities.

The security industry is now taking advantage of UV CCFL tubes thanks to the recent discovery that chemical substances used in the manufacture of nitrogen-based, high explosives such as Pentaerythritol tetranitrate (PETN) fluoresce and phosphoresce when irradiated with around 365-nanometer (nm) ultraviolet light. It takes less than 30 seconds to reveal the presence of PETN (Figure 1) which is a major component of C-4 and Semtex explosives used in making bombs.

Figure 1: Because of the spectral response of the PETN chemical, UV emitters can be used to detect traces of bomb-making materials at secure checkpoints.

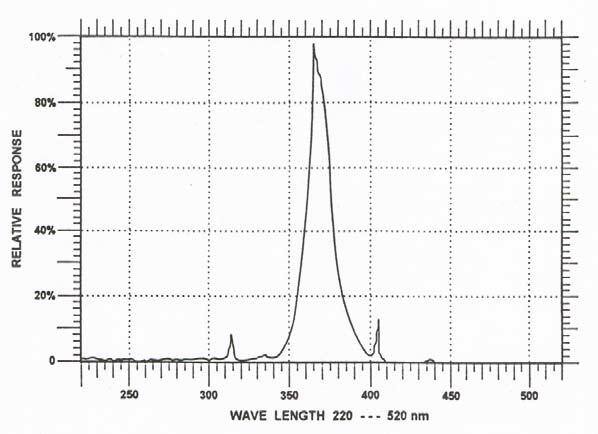

A great source for CCFL UV tubes comes from JKL Components. These CCFL bulbs exhibit good spectral purity centered around a 365-nanometer wavelength (Figure 2). They are made in various sizes, from 25 mm to 240 mm with optical intensities in 80, 450, and 1,600 µW/cm2 at 1 inch. The life rating is around 5,000 hours.

Figure 2: The spectral response of glass CCFL tubes is fairly narrow when compared to the broader spectral content of white CCFL bulbs.

It should be noted that this is actually a half-life rating. This means every 5,000 hours, the intensity is 50 percent of what it was. As a result after 15,000 hours, the intensity is still 25 percent initial brightness. If dimming techniques are employed in the chosen inverter, the usable life expectancy can be extended even more.

This brings up a characteristic of CCFL glass tube emitters. They require an inverter to step the typically low voltage supply, up to the much higher ac striking voltage (to get it started), and operating voltage and frequency. Since voltage characteristics are dependent on diameters and lengths, JKL provides a table of bulb requirements so you can match these to one of the many CCFL inverters available.

The solid state of things

As you know, LEDs are no longer just red, yellow, and green. The semiconductor industry has been exploiting material and fabrication technology to yield new LED wavelengths and power ratings all the time, and engineers using UV have benefited.

A good example of this comes from Lumex with its QuasarBright through-hole family of ultraviolet LEDs. These parts have an outstanding 50,000 lifespan with up to 70 percent lower power consumption than CCFL, according to Lumex. The family has output power from 4 to 6 mW.

What is particularly interesting is the fairly narrow increment of spectral wavelength outputs that Lumex offers in this family. For example, the parts are available at 355, 365, 377, 385, 405, and 415 nm. This lets the engineer use a fairly specific wavelength without having to resort to using higher-cost filters or UV lasers.

Specific wavelength products can make the difference between a viable design and one that just doesn’t work well enough. For example, you may want to target and destroy a very specific bacteria that 377 nm kills effectively. Having to use 355- or 405-nm spectrum light may not give enough intensity at the 355-nm wavelength to kill the bacteria.

Packaged in a rugged TO-46 metal can with a clear glass lens (Figure 3), the family is easy to interface to a low cost power supply. Typical forward voltage drops of 3.3 V with 20-mA current is easy enough to design without having to source an oddball supply. No high voltage is present either making certification and safety requirements easier as well.

Figure 3 - The QuasarBright gold colored TO-46 metal can is a tough and rugged package with a built-in lens assembly.

More light on the subject

As the available wavelengths, power levels, and power densities improve, more applications will continue to open up for UV parts. For more information, use the provided linked products and technology pages on the DigiKey website.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国