MCU Solutions for White Goods Tighten Focus on Low Power, Safety

投稿人:电子产品

2015-10-14

The design of white goods such as washing machines, refrigerators, and dishwashers has evolved in positive new directions over the past 10 years. Although performance metrics such as How clean? How fast? How cold? are still important, they’ve been joined by design goals that target energy efficiency, safety and, in higher-end models, Internet connectivity.

The EU, the U.S., and many developed countries have mandated energy-efficiency standards that push the average usage of a washing machine, for example, down to around 150 kWh per year. Every subsystem has a role in minimizing energy consumption but MCUs have the critical task of executing sophisticated motor-control algorithms that optimize the motor’s energy use.

Automated programmability – the use of pre-sets on washers, dryers, and dishwashers, for example – has made meeting energy-saving goals more complicated. In order to offer customer convenience while still optimizing energy use, designers are employing sensors to measure the size of the load and water temperature.

While energy consumption is on every designer’s mind, regulating bodies around the world have also issued quality and safety standards for white goods. IEC/UL 60730 sets standards for hardware and software to protect users from injury and the machine itself from damage.

Communications capability is also becoming more important with the first step being the ability to communicate with a smart meter. Internet access to the appliance is also a consideration and that logically leads to greater security.

BLDC motor control

Aggressive energy-efficiency goals are driving a migration from motors with built-in position sensors to sensorless brushless DC (BLDC) and permanent-magnet synchronous motor (PMSM) motors. Controlling BLDC motors entails some design complexity. PMSM control is more sophisticated and compute-intensive. It is typically used in high-end appliances and industrial motor control.

AC-powered BLDC motors have permanent magnets fixed to the rotor and windings on the stator. The magnets create rotor flux; the energized stator windings create electromagnetic poles. By energizing the stator phases (e.g., a 120° rectangular wave for 3-phase power), a rotating field on the stator is created.

The spatial relationship between the rotor and the rotating field must be tightly controlled to produce torque. This synchronization requires knowledge of the rotor position. A larger number of poles on the rotor typically create more torque for the same current but this advantage eventually disappears if the space between the magnets is reduced too much.

MCU vendors offer extensive software-development support that makes it possible for an MCU to sense rotor position when the rotor is stationary – and also at high rotational speeds. The change over to sensorless motors using BLDC control also requires specific hardware, either as a device on the motor-control card or integrated into the MCU itself. This hardware includes: A fast 3-phase pulse-width-modulation (PWM) output timer; dedicated high-speed comparators for overcurrent detection and rotor-position detection; a D/A converter; a programmable gain amplifier (PGA) and variable amplification factors; and fast operational amplifiers.

The PGA should have a high slew rate. It is also desirable for it to support a software-selectable, variable amplification factor. When the PGA is integrated on-chip, the need for an external amplifier for voltage detection or overcurrent detection is eliminated.

The two-channel, high-speed comparator typically utilizes the PGA output as its input signal in one channel, which enables overcurrent detection for the BLDC inverter circuit. The other comparator channel lets the user select any combination of positive and negative inputs to implement rotor-position detection and manage the motor’s back EMF signals.

Numerous MCU vendors, including Texas Instruments, STMicroelectronics, NXP/Freescale, Microchip, and Renesas offer BLDC hardware/software products. Renesas, for example, has positioned its 16-bit, 24 MHz RL78/G1G MCU family for BLDC. All members integrate a three-phase PWM timer, a two-channel comparator, an 8-bit D/A converter, and a PGA capable of software-controlled amplification.

A typical Renesas RL78/G1G device is the R5F11EFAAFP#30. Also available is the YR0K5011EFS000BE starter kit for the RL78/G1G MCU family. A block diagram of the core RL78/G1G functions is shown in Figure 1.

Figure 1: The Renesas RL78/G1F family has been designed to support BLDC motors. (Courtesy of Renesas Semiconductor)

Renesas recently introduced its RL78/G1F family that integrates more functions and offers higher clock rates and on-chip memory.

PMSM control

Both BLDC and PMSM motors are built using permanent magnets on the rotor and windings on the stator. They differ primarily in the drive signals that the inverter supplies to the motor: BLDC motors are controlled with rectangular (or in some instances trapezoidal) waveforms, PMSMs motors are controlled by sinusoid waveforms to match the back EMF waveform of each motor’s windings.

The field-oriented-control (FOC) technology used to control PMSM motors requires considerably more computing power than rectangular and trapezoidal control schemes of BLDC. This implies higher MCU clock rates, 32-bit architectures, multiple ADCs, more on-chip ROM for the software libraries, and more pins on the device.

The same vendors that offer BLDC hardware/software products also offer PMSM packages. Renesas, for example, has positioned its 100 MHz RX62T and RX63T families for PMSM applications. Based on Renesas’ proprietary 32-bit RX core, they integrate multifunction timers, a high-speed 12-bit A/D converter, and a 10-bit A/D converter among other peripherals. A higher-performance device is the R5F563TEDDFB#V0 with 512 Mbits of Flash memory and 144 pins. Also available is the R0K50563TS000BE starter kit for the RX63T family.

STMicroelectronics is another vendor with multiple MCU families for BLDC and PMSM control. Those capable of PMSM control and based on the company’s STM32 architecture and ARM Ltd.’s 32-bit Cortex-M0, M3, and M4 cores. A typical mid-range product is the 72 MHz, STM32F303VCT7. The evaluation kit for STM32F303 MCUs used in PMSM applications is the STEVAL-IHM042V1.

Since an integral part of the PMSM solutions from all MCU vendors is the application software and FOC software libraries they make available, it is worthwhile to briefly describe the features of STMicro’s development tools, which are assembled into hardware/software kits. Other vendors offer similar products.

With STMicro’s developer’s kit, developers can acquaint themselves with the design process with a demo using the LCD and the joystick included in the kit. Figure 2 shows the kit components. Among the parameters that can be fine-tuned or changed and then used to control the PMSM motor are:

- Real-time tuning of torque, flux, and speed PIDs

- Back-EMF observer gain tuning (for sensorless control)

- Variation of target speed (speed control) or target torque and flux (torque control)

- Bus-voltage and power-stage temperature monitoring

- Selection of variables to put on output for DAC functionality implementation

Figure 2: STMicro’s motor-control kit for STM32F303 MCUs. (Courtesy of STMicroelectronics)

The software in STMicro’s motor-control kit can handle both PMSM and induction motors. An important addition is a vector-control library. It is compatible with IAR, Keil, and Green Hills tool chains. The source files are free upon request and include:

- Three current-sensing methodology options

- Isolated

- Three shunt resistors with dual sample-and-hold utilization

- Proprietary algorithm for single shunt resistor

- Three rote-position feedback options

- Tachometer (for induction motors only)

- Hall sensors (60° and 120° placement

- Sensorless (PMSM motor only)

Execution time for FOC in sensorless mode on the STM32 F1 series for PMSM motors is less than 21 µs (and less than 10 µs for STM F4 MCUs). The total CPU load at 10 kHz sampling time is less than 25 percent and code size is less than 14 Kbytes.

Safety requirements

In addition to energy efficiency, standards and regulatory bodies have published quality and safety standards for white goods. IEC/UL 60730, for example, sets standards for hardware and software to protect users from injury and the machine from damage. Specifically, IEC/UL 60730 details test and diagnostic methods to ensure the operation of embedded control hardware and software for appliances are safe.

White goods are subject to IEC 60730 Class B compliance, which has two simple components: The ability to prevent unsafe operation of the controlled equipment; and, software that includes code intended to prevent hazards if a fault occurs in the appliance.

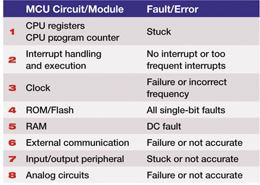

The MCU must execute specific software tests following start-up and periodically during operation to ensure that the system is operating as designed. These include CPU and RAM tests; ROM/flash tests; clock tests, and peripheral tests. Figure 3 identifies the MCU hardware subsystem or function along with the types of faults in that subsystem that must be identified and corrected for IEC/UL 60670 compliance.

Figure 3: To achieve IEC 60730 compliance, tests must verify the proper operation of eight hardware subsystems in an MCU or control module of an appliance. (Courtesy of IEC)

ROM/Flash tests are based on cyclic redundancy checking (CRC), which identifies all single-bit errors and most of multi-bit errors. The CRC values used as checksums can be calculated in software using either a look-up table or bit shifting; look-up tables require more code space but fewer CPU cycles. Some companies, including Renesas, offer MCUs with a dedicated CRC-calculation circuit that can generate a CRC value for one byte of data in two machine cycles.

Although the tests are performed in software using low-level software test routines, in many instances the test can be successful if additional peripherals are integrated into the MCU. Among the most important peripherals are:

- Error Correcting Code (ECC) Flash

- Deadman Timer (DMT)

- Windowed Watchdog Timer (WWDT)

- Backup system oscillator

The WWDT is critical because it assures the correct execution of the MCU’s control algorithms. For Class-B products, the WWDT must meet four requirements: It must have a separate time-based oscillator; it cannot be disabled through software, it must implement hardware-based reset; and, provisions must be made for obtaining a safe I/O state following initialization and/or hardware reset.

All major MCU vendors offer IEC 60730 solutions in their development kits.

Microchip Technology has joined this group with its 16-bit dsPIC33EV Digital Signal Controllers (DSCs), which are part of the company’s dsPIC33EV family. The “EV” family is the first dsPIC33 DSC with Error Correcting Code (ECC) Flash for increased reliability and safety.

This new family provides 5 V operation for improved noise immunity and robustness for environments encountered by appliances and in automotive applications. For safety-critical applications, the dsPIC33EV devices also include CRC, Deadman Timer (DMT), and Windowed Watchdog Timer (WWDT) peripherals as well as a backup system oscillator and certified Class-B software.

Devices in the dsPIC33EV family are available in 28 SOIC, 28 QFN, 28 SPDIP, 44 TQFP, 44 QFN, 64 TQFP, and 64 QFN packages, with Flash memory ranging from 64 KB to 256 KB, including options with and without CAN. A typical part in DS includes up to six motor-control PWMs, 12-bit ADC, and operational amplifiers.

Conclusion

The design of white goods has become more complicated by energy and safety goals mandated by national and regional government bodies such as the EU. Meeting these goals has led to a migration to sensorless motor-control designs using BLDC and PMSM motors. Software development tools and libraries are just as important as the peripheral integration on the MCU. Vendors have developed a variety of solutions including 16-bit and 32-bit MCUs. Sometimes DSP capability is also included for faster algorithm execution.

For more information about the parts discussed in this article, use the links provided to access product pages on the DigiKey website.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国