用于系统功率循环的高压侧 MOSFET 输入开关选择

投稿人:DigiKey 北美编辑

2024-11-20

功率循环在确保电子应用不间断运行方面发挥着关键作用,尤其是那些部署在偏远地区并由电池供电的应用。断开和重新连接电源可以重置因持续不活动或系统挂起而失去响应的系统。一种有效且广泛使用的功率循环方法是利用监控电路的低电平有效输出来驱动高压侧 MOSFET 输入开关。

电压监视器或监控电路可为其逻辑电平输出提供两种选择:低电平有效和高电平有效输出信号。这适用于推挽输出拓扑或带有上拉电阻的开漏输出输出拓扑。

- 低电平有效,当输入条件满足时,输出变为低电平,当输入条件不满足时,输出变为高电平

- 高电平有效,当输入条件满足时,输出变为高电平,当输入条件不满足时,输出变为低电平

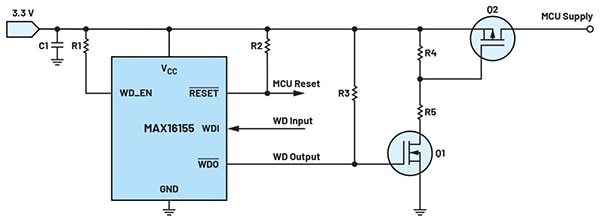

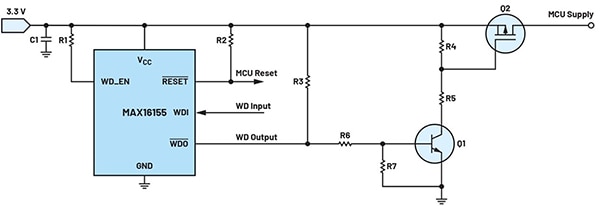

监控电路通过跟踪电压供应或通过使用看门狗定时器检测不活动状态(或两者方式兼而有之)来监控系统活动。当这些保障措施检测到问题时,功率循环会打开,然后关闭电源和下游系统之间的通路,使单片机 (MCU) 进入复位过程。电路高压侧的输入开关(图 1)用于控制下游电子系统的电源。

当然,选择合适的元件并应对潜在的挑战(如功率循环过程中可能产生的发热和开关噪声)至关重要。

图 1:使用高压侧开关保护下游电子系统以免在断电情况下出错的应用电路。(图片来源:Analog Devices, Inc.)

图 1:使用高压侧开关保护下游电子系统以免在断电情况下出错的应用电路。(图片来源:Analog Devices, Inc.)

当然,选择合适的元件并应对潜在的挑战(如功率循环过程中可能产生的发热和开关噪声)至关重要。

高压侧电源开关

功率循环可用于各种应用,以提高系统可靠性并减轻潜在的损坏,包括无线收发器、医疗设备、智能家居设备、电源和消费电子产品。

金属氧化物半导体场效应晶体管 (MOSFET) 具有低导通电阻、高开关速度和高输入阻抗等特点,因此广泛用于功率循环。

监控电路的输出可以控制 MOSFET 的栅极,从而有效打开或关闭 MOSFET 以进行循环供电。这种方法允许系统从无响应状态中重置和恢复,从而确保最佳的系统可靠性。

采用这种方法的开发人员可以选择使用 N 沟道或 P 沟道 MOSFET,但许多人更倾向于使用 P 沟道方法,因为开启和关闭 P 沟道 MOSFET 所需的条件和电路没有 N 沟道 MOSFET 那么复杂。

对于 P 沟道 MOSFET,栅极电压必须低于源极电压才能导通,而对于 N 沟道 MOSFET,栅极电压必须高于源极电压才能导通。

当 N 沟道 MOSFET 用作高压侧输入开关时,低栅极电压会导致开关断开并切断电源。虽然 N 沟道 MOSFET 通常具有更高的效率和性能,但在这种情况下,需要额外的电路(如充电泵)来产生正的栅源电压 (VGS),以确保开关完全重新连接电源。

使用 P 沟道 MOSFET 时就不需要额外的电路,它可以由负 VGS 打开,从而简化了应用设计,但代价是导通电阻增大,能效降低。

实现 P 沟道高压开关

采用 P 沟道方法时,用于控制 MOSFET 的栅源电压必须至少低于电源的栅源阈值电压 VGS(th),以使电流从源极流向漏极。另一个考虑因素是确保漏极和源极之间的电压 (VDS) 在规定范围内工作,以确保器件不会损坏。

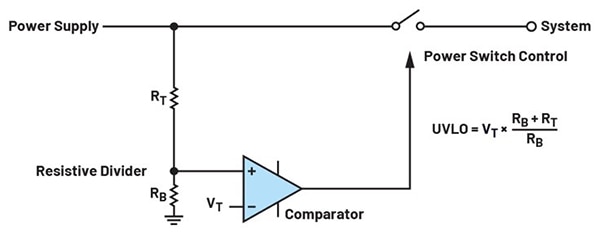

当低电平有效监控电路输出连接到 P 沟道 MOSFET 的栅极时,OUT 引脚会在超过指定阈值时将栅极拉低,从而激活从供应电压到负载的连接。当该电压低于阈值时,OUT 引脚变为高电平,P 沟道 MOSFET 关断,负载与该供应电压断开。

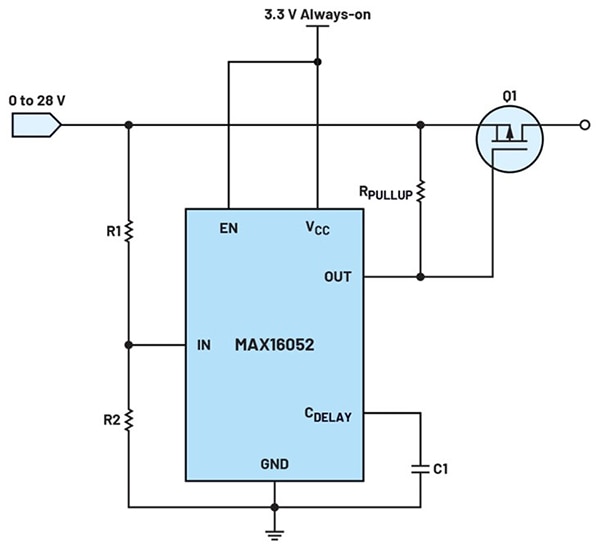

开发人员可以通过将器件的 OUT 引脚直接连接到 P 沟道 MOSFET 的栅极来实现高效的过压保护电路。这种稳健的方法使用 P 沟道 MOSFET 作为高压侧开关,连接到 Analog Devices, Inc. MAX16052 功率管理 IC(图 2),确保负载与供应电压相连。

图 2:P 沟道 MOSFET 用作高压侧开关以实现过压保护。(图片来源:Analog Devices, Inc.)

图 2:P 沟道 MOSFET 用作高压侧开关以实现过压保护。(图片来源:Analog Devices, Inc.)

当开漏 OUT 引脚处于高阻抗状态时,受监测电压与 P 沟道 MOSFET 栅极之间的外部上拉电阻会使栅极保持高电平。当受监测电压超过阈值时,OUT 引脚进入高阻抗状态,从而关闭 P 沟道 MOSFET 并断开负载与供应电压的连接。反之,当受监测电压低于阈值时,OUT 引脚将栅极引脚拉低。

MAX16052 与 ADI 的 MAX16053 构成了一系列小型、低功耗、高电压监控电路,具有定序功能,均采用紧凑型 6 引脚 SOT23 封装。MAX16052 提供高电平有效开漏输出,而 MAX16053 则提供高电平有效推挽输出。两者都可对低至 0.5 V 的输入提供可调节的电压监控,并使用内部固定 0.5 V 阈值的高阻抗输入 (IN) 执行电压监控。

使用看门狗定时器

看门狗定时器 (WDT) 可以增强监控电路在满足监控条件时且输出信号低的情况下的保护能力。在这些情况下,看门狗定时器可以检测到一定时间内没有脉冲或转换(称为看门狗超时 (tWD)),然后就会激活单片机复位或启动功率循环。

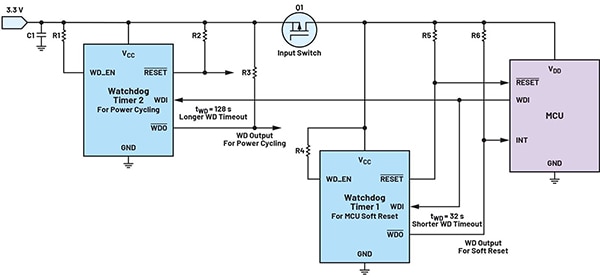

当正电源电压 (VCC) 超过最低工作电压时,即使低于复位阈值,ADI 带看门狗定时器的 MAX16155 毫微功耗监控器也会启动复位输出。使用两个 WDT 的应用(图 3)可以在 32 秒未活动后启用单片机软复位,在 128 秒未活动后启用系统功率循环。

图 3:在此配置中,看门狗定时器 1 将启动软复位,而看门狗定时器 2 则启动系统功率循环。(图片来源:Analog Devices, Inc.)

图 3:在此配置中,看门狗定时器 1 将启动软复位,而看门狗定时器 2 则启动系统功率循环。(图片来源:Analog Devices, Inc.)

驱动 P 沟道高压侧开关的一种选择是使用 NPN 双极结型晶体管 (BJT) 作为逆变器,将看门狗输出的会关闭 NPN 晶体管的低电平信号转换为会通过上拉电阻关闭 P 沟道 MOSFET 的高电平信号(图 4)。当系统处于激活状态时,看门狗输出 (WDO) 为高电平,通过电阻器将信号发送到 NPN 晶体管的基极,使其开启。

图 4:NPN 双极结型晶体管 (Q1) 驱动 P 沟道 MOSFET (Q2)。(图片来源:Analog Devices, Inc.)

图 4:NPN 双极结型晶体管 (Q1) 驱动 P 沟道 MOSFET (Q2)。(图片来源:Analog Devices, Inc.)

连接到 MOSFET 栅极和源极的电阻分压器控制 VGS。当 NPN 晶体管导通时,它会将电阻分压器拉低,使栅极电压低于源极电压,从而导通 P 沟道 MOSFET,为系统供电。

如果微处理器反应迟钝或未能在 MAX16155 看门狗定时器预定义的超时时间内发送输入脉冲,则会发生看门狗超时事件,导致 WDO 引脚断定为低电平。这一动作会将 NPN 的基极拉到地电位,使其关闭。当 NPN 晶体管关闭时,P 沟道 MOSFET 栅极和源极的电压相同,从而关闭 MOSFET 并切断微处理器的电源。

一旦看门狗定时器的 WDO 输出返回高电平,系统就会恢复正常运行。然后,微处理器会定期向 WDI 引脚发送脉冲,防止进一步超时。NPN 晶体管导通,使高压侧 MOSFET 保持导通,确保为微处理器持续通电。

双极结型晶体管的低成本是 P 沟道高压侧开关的设计优势,但需要借助额外的外部元件(如电阻器)进行适当微调。

使用 N 沟道 MOSFET 驱动电路

与双极晶体管相比,使用 N 沟道 MOSFET 控制高压侧 P 沟道 MOSFET 有几个优点。

N 沟道 MOSFET 具有较低的导通电阻,可减少功率损耗并提高效率。它还能快速切换,改善系统响应时间。它开关损耗更低,工作频率更高,是电池供电型设备之类高能效应用的理想之选。此外,栅极驱动要求也比 BJT 低,从而简化了驱动电路,减少了元件数量。

看门狗输出可直接控制 N 沟道 MOSFET 的栅极。WDO 的上拉电压必须与 MOSFET 的栅极阈值电压 (VGS(th) 匹配,才能正常工作。系统激活时,高电平 WDO 信号会打开 N 沟道 MOSFET(图 5 中的 Q1),然后打开 P 沟道 MOSFET(图 5 中的 Q2),为系统供电。系统不活动时,低电平 WDO 信号会关闭 Q1,从而关闭 Q2,并切断电源。

图 5:N 沟道 MOSFET(Q1)驱动 P 沟道 MOSFET(Q2)。(图片来源:Analog Devices, Inc.)

结语

使用 N 沟道或 P 沟道 MOSFET 驱动高压侧开关都是系统功率循环的可靠方法。采用 NPN 双极晶体管和附加元件的 P 沟道方法成本较低,而成本较高的 N 沟道方法更适合高频开关。具体哪一种方法最佳,则取决于开发人员的设计偏好和应用要求。

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。