Energy Harvesting to Power Wearable Networks

投稿人:DigiKey 欧洲编辑

2012-10-03

The development of low power silicon devices has opened up opportunities for energy harvesting to provide most, if not all, the power for linking devices around the body. Powered by the movement or heat of the body, these ‘personal area networks’ (PANs) can be used to link devices around the body using the new generation of ultra-low power wireless silicon transceivers.

The energy harvesting elements – whether from movement or thermal energy – are most often used to charge a flexible polymer battery to provide the power for the wireless link. This works most effectively when only small amounts of data are sent, for example to provide updates on position or medical information, rather than the higher energy load of streaming music or video around the body. This smaller duty cycle is better suited to the lower power produced by energy harvesting.

Several different techniques for harnessing the movement of the body are being developed. One well established energy harvesting technology for PANs are piezoelectric vibration sensors that can be used to capture the vibrational energy. This is particularly relevant to footwear, particularly training shoes, where the constant movement generates current to power a wireless link. This has already been implemented in ‘smart’ shoes from Nike that provide a link back to a mobile phone or a wearable terminal, providing data such as the number of footsteps or average speed.

Researchers at the University of Wisconsin-Madison have developed an in-shoe system that harvests the energy generated by walking, claiming almost 20 W of power. The process, called "reverse electrowetting" by the researchers, converts the movement to electricity through a microfluidic device, where thousands of microdroplets (of an undisclosed non-toxic, inexpensive liquid) interact with a nanostructured substrate. The process is said to have a power density of up to one kilowatt per square meter. This feeds a hermetically sealed battery to power the network link.

A different approach has been used by researchers at IMEC in Belgium who have developed a micromachined cantilever with a piezoelectric layer of aluminum nitride between metallic electrodes. This forms a capacitor that generates charge as the cantilever bar vibrates, storing power. The voltage across the capacitor can then be harvested to drive wireless circuits. One key advantage of this approach is that the MEMS devices can be built on standard 6 inch CMOS wafers. This provides potential for integration alongside the wireless transceivers to deliver power directly or by distribution around clothing.

The Midé Technology V22BL cantilever piezoelectric crystal can be used to harvest energy from such sources of vibration as low as 26 Hz. However, the vibration environment has to be fully understood and this can be difficult with a system such as a shoe or a walking person, so the best way to do this is to measure the vibration using an accelerometer. Once the data is captured, a Fast Fourier Transform (FFT) extracts the frequency information. Midé offers a standalone vibration characterization device that can be easily installed into many different vibration environments to capture data in hard-to-reach areas. A built-in timer allows the capture of many different types of vibration and a simple USB interface allows the designer/user to easily characterize any vibration. This can also help make sure that the crystal is not exposed to excessive vibrations that can damage the device and shorten its useful life.

Figure 1: The Midé Technology V22BL cantilever piezoelectric crystal.

Harvesting the energy is not just about the sensor. The power conversion is also critical, especially around the body. Linear Technology has integrated a low-loss full-wave bridge rectifier with a high efficiency buck converter that is optimized for such high output impedance energy sources. The LTC3588-2 is an ultra-low quiescent current under-voltage lockout (UVLO) mode with a 16 V rising threshold to provide efficient energy extraction from piezoelectric transducers with high open circuit voltages.

Researchers in New Zealand have also developed a class of variable capacitor generators known as "dielectric elastomer generators" (DEGs) that can be used to power body networks. The use of the elastomers has previously been limited by the need for bulky, rigid, and expensive external circuitry, but the researchers at the Auckland Bioengineering Institute's Biomimetics Lab have developed a flexible, soft dielectric elastomer generator whose stretchable circuit elements are integrated within the membrane. The generator achieved an energy density of 10 mJ/g at an efficiency of 12 percent and simply consisted of low-cost acrylic membranes and carbon grease mounted in a frame, making it easier to use in clothing to power a network link.

Thermal power

Thermal sensors can also be used around the body to generate power from a temperature difference. The Peltier effect is often used for cooling electronic systems but can also be used to generate current from the temperature gradient between the interior and exterior of clothing. This can be used to trickle feed a battery or power a wireless link directly.

Heat-powered networked body electronics have been demonstrated using the MSP430 microcontroller from Texas Instruments and a flexible thermoelectric film technology to provide the power. These were integrated into armbands linked to wireless sensor devices that collected and transmitted physiological data using only the wearer’s body heat as their primary energy source.

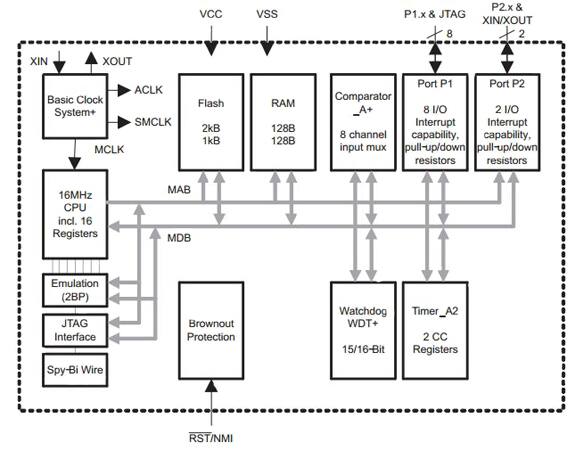

The MSP430 is an ultra-low power controller with a 16-bit RISC architecture that is highly transparent to the application. All operations, other than program-flow instructions, are performed as register operations in conjunction with seven addressing modes for source operand and four addressing modes for destination operand. The CPU is integrated with 16 registers that provide reduced instruction execution time so that the register-to-register operation execution time is one cycle of the CPU clock. This, coupled with low power ferroelectric memory, provides the very low energy consumption that enables it to be powered by the thermoelectric film. In the active mode it uses 220 µA at 1 MHz and 2.2 V, while in standby it uses just 0.5 µA. The ultra-fast wake-up from standby mode takes just 1 µs so the controller can be shut down and powered up just when it is needed for capturing the sensor data and sending it to the transmitter.

This highlights a key driver for the increasing use of energy harvesting for medical systems, monitoring the heart and other organs around the body.

Figure 2: Functional Block Diagram of the TI MSP430F20x1.

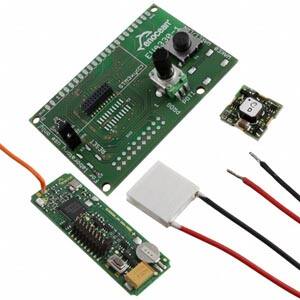

The Cymbet CBC-EVAL-09 thermal evaluation board provides a Peltier effect device to drive a wireless link, integrating the DC/DC converter needed to provide the power. Similarly EnOcean’s EDK312C evaluation kit also uses thermal energy to power a wireless link.

The operation of these devices starts at typical 20 mV from a 2 Kelvin temperature difference for a standard low-cost Peltier element. The output power is in the range from μW to mW and depends on the actual temperature difference at the Peltier element. The ECT 310 in the development kit is designed and optimized for powering EnOcean radio modules for wireless sensors where the input voltage range of 20 mV to 50 mV corresponds to an output voltage range between 3 V to 4 V.

A typical thermo-driven sensor consists of a sensor element, a small Peltier element, the ECT 310 DC/DC converter and an EnOcean STM 300 or STM 312 radio module that already has energy storage on board.

Figure 3: The EnOcean thermal energy harvesting evaluation kit.

Solar

Solar cells can also be a key provider of power for wearable electronics. With many watches already powered by solar cells, the idea is extending to power wireless devices. EnOcean’s ECS300 solar cells can also be used with the EDK312C evaluation kit as a source of power.

Solar cell technology has become more flexible, allowing cells to be more easily integrated into external clothing such as coats. The efficiency of the cells has also increased so that they can generate power from both outdoor and indoor lighting, boosting their use. While they can be used to power devices directly, the more common route is to use them to trickle charge lithium ion batteries that are light and can also be integrated into clothing. This provides the power for displays and music players, with power left over for LEDs and electroluminescent displays for fashion purposes.

The IPS-EVAL-EH-01 evaluation board from Infinite Power Solutions also demonstrates universal energy harvesting, efficient energy storage, and ultra-low power output regulation in a convenient form factor tailored for the development of autonomously powered body electronics using solar cells.

Figure 4: The IPS energy harvesting evaluation board.

The harvested energy is stored in the integrated solid-state, rechargeable, thin-film Micro-Energy Cell (MEC). The MEC, also known as a Solid-State Battery (SSB), is able to last the lifetime of the application with no battery replacement required and enables deeply embedded applications to run autonomously and maintenance-free for decades, providing the lowest cost-of-ownership power solution for low power microelectronic systems.

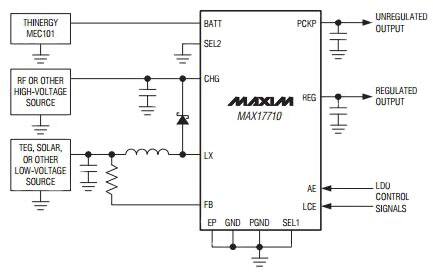

In addition, the IPS-EVAL-EH-01 incorporates the Maxim MAX17710 Energy Harvesting Power Management IC (PMIC) to handle poorly regulated, highly variable inputs typical of energy harvesting sources such as solar, RF, thermal or vibration, and an amorphous silicon solar from Sanyo Energy. The Amorton solar technology uses amorphous silicon, making the cell thinner for a given power output. This means that an ultra-thin amorphous silicon film of less than 1 µm can be produced and used for power generation. By using a plastic substrate, this film can be made flexible.

This self-charging, self-regulated platform provides an example energy harvesting and energy storage system intended to power small microelectronic devices such as remote wireless sensors that require an autonomous or perpetually powered energy source without maintenance.

Figure 5: A simplified circuit diagram for the MAX17710 PMIC.

An integrated unique “off-active” event-driven activation system enables a quiescent current of 1 nA between target system active periods and there are inputs for external AC or DC energy sources if necessary. These input energy sources can be connected to the IPS-EVAL-EH-01 to provide charge for the integrated MEC. Additionally, the user or connected target system can select the required regulated output voltage from the three available options of 1.8 V, 2.3 V, and 3.3 V.

The system can operate in three power modes: high power regulation, low power regulation, and off-active mode. In the high power regulation mode, the system quiescent current is well below 1 µA and output regulation voltages are tightly controlled, making it suitable for full power system operation. In low power regulation mode, the quiescent current is typically below 75 nA with output regulation less tightly regulated, suitable for real time clock, low power processor sleep states, and memory backup conditions. In the off-active mode, the target system is completely isolated from the integrated energy storage device, using just 1 nA of quiescent drain. In this state the system can accept input charge energy and can respond to input events allowing the system to wake to full power and operation on significant input events.

IXYS provides IXOLAR SolarMD for charging various battery-powered and handheld consumer products such as mobile phones, cameras, music players, and toys and so can provide the power for networking around the body. A typical cell efficiency of 22 percent allows the cells to generate power from low light conditions and increase battery life and run time in a small footprint.

A different approach comes from Clare with a string of solar cells with switching circuitry. When operating in sunlight or a bright artificial light environment, the optical energy will activate the cell array and generate a voltage at the output. The solar cells of the CPC1822 generate a floating source voltage and current sufficient to drive and power CMOS ICs, logic gates, or provide the trickle charge for a battery.

Conclusion

There are several different energy harvesting sources that can be used to either power networking devices directly or charge up a thin film storage device to handle the wireless link. Using the vibration or movement of the body, local heat, or solar energy provides a wide range of options for developing systems that do not need to replace the battery or regularly re-charge the equipment from the mains.

While these technologies have been taken up first in medical applications to provide monitoring of data around the body and link it back to a central data capture system, the technology is making its way into every day wearable systems. The development of new materials and techniques for capturing the energy, such as thermoelectric or elastomer films, coupled with ultra-low power silicon controllers, such as the TI MSP430 family, and low power wireless links, is making self-powered personal area networks a practical reality.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国