Easing the Interface Between Human and Machine

投稿人:DigiKey 欧洲编辑

2012-02-02

It is easy to think of touchscreens as the most important part of the human/machine interface in modern industrial control – slick images of operators poring over onscreen mimic diagrams have seduced us into thinking this is the way that all modern industrial machinery should be controlled.

In fact, a multitude of other components enable people to interact with industrial machines. Switches, for example, seem pretty straightforward, but the switch you use for an emergency machine stop must be engineered for high reliability. Rotary switches and thumbwheels enable operators to enter simple discrete machine configurations, while slider and rotary potentiometers enable more nuanced settings. Navigation joysticks can be used to move the point of control round a static user interface, while potentiometer-based joysticks can be used in safety-critical situations such as the positioning of the work head in a machine tool.

Additionally, buzzers and sounders can provide audio warnings, while embedded microphones can be used in feedback loops to ensure that the sounders can be heard above the ambient noise, especially important in a noisy workplace.

Touch entry systems offer a variety of ways of controlling an industrial machine. Various forms of touchscreen technology, especially those tuned for working in harsh environments, enable developers to create sophisticated user interfaces that adapt to the way in which the machine is being used.

Stop before you start

Most industrial machinery needs some sort of emergency stop button to ensure that it is easy to stop it when things go wrong. In such situations, visibility and reliability are key factors in ensuring operators can find it easily and know that it will work when they press it. Omron Electronics’ A165E is an interesting example of the type: the switch has a safety lock to prevent misuse, and a direct opening mechanism so that the contacts can be accessed and opened in an emergency, such as if they are welded together. Versions are available with a yellow ring that surrounds the switch, to make it even more visible, and an internal light. Various switching options are available, including SPST, DPST and TPST.

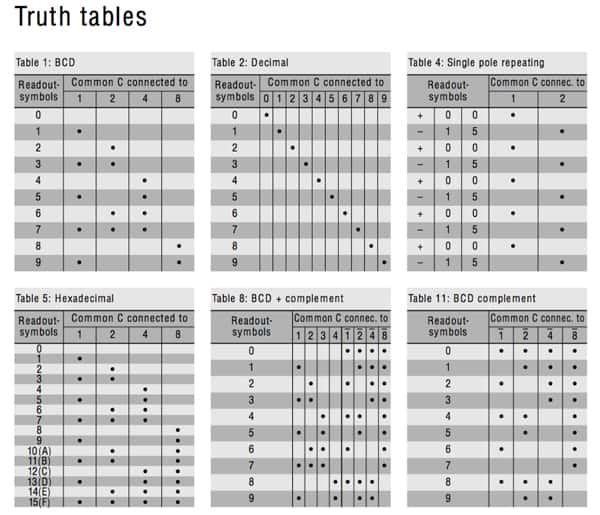

Once you can be sure of stopping your industrial machinery, the next step is to configure its operation. We may be used to drop-down menus and swipe gestures on our phones and laptops, but simple machinery demands simple interfaces, such as rotary position switches that can be hardwired to set certain functions. C&K’s RTA series of up to four-pole coded rotary switches are designed for setting up appliances, medical equipment, alarm systems, building automation, or heating and ventilation systems. The series, which has so many options that C&K offers a “Build a Switch” guide in the datasheet, can be configured to produce either decimal or hexadecimal codes on its outputs, depending on the position of the switch.

Figure 1: Rotary switches can be set up to produce a variety of coded outputs.

The RTA series of rotary switches turn in the same plane as the panel through which they are mounted. Cherry’s PA, PB and PE series of selector switches are mounted through a panel and rotate orthogonally to it, making them suitable for mounting next to each other in blocks. Like the C&K rotary switches, the three series offer myriad options, including decimal, BCD complement, BCD and complement, hexadecimal and repeating single-pole outputs (Figure 1). There are also options to order the switches with custom output codes (by special order) and with an extended PCB so that you can mount diodes and resistors to the back of the switch, turning its pure digital coding into a partially analog coding. Matching connectors are also available.

Combinations of switches can be built up into more complex user-interface devices. CH Products’ 1000 series of microswitch joysticks combine standard microswitches with a mechanical yoke system so that movement on a single or dual axis directly switches up to 16 A at 240 V. The joysticks are supplied as standard with a square gate, which defines how the stick can move. There are options to add other gates that will limit the stick to single-axis ( | ), cross ( + ), or diagonal ( X ) movement. There are also options for various lever lengths and knobs, as well as to add a gaiter to keep the dust out of the joystick’s mechanism.

On the slide

Switches can provide ‘digital’ (on/off and encoded) outputs, as well as limited analog outputs, as in the case of Cherry’s selector switches. More subtle control requires analog inputs, often from potentiometers.

TT Electronics offers its PSxxG series of linear pots, with or without dust covers. You would think a linear pot would be pretty straightforward, but these are offered in seven resistance ranges and three different ‘resistance tapers’. In other words, these options vary in the way in which resistance changes along the length of the potentiometer’s slide, suiting audio applications, straightforward linear applications in which the offered resistance varies with the distance of the slider from its end stop, and ‘reverse audio’ applications. The parts also have a stable sliding force, so it takes as much effort to move it over the first quarter of its action as over the last quarter (important for the user feedback it provides), a 200,000 cycle operating lifetime, and various options for the operating lever.

CH Products offers the 4000 series of potentiometer joysticks, bringing the true analog output that is missing from most microswitch joysticks. The joysticks use plastic-film potentiometers, which are claimed to give the joystick an operating life of millions of cycles. The potentiometers are set up as potential dividers, with the standard part having 340° tracks, so that if the shaft of the joystick is deflected across the full standard range of +/-27.5°, the output with a typical 12 V supply would swing from 5 to 7 V around a 6 V center value. Another potentiometer variant enables rail-to-rail output swings, while a third option acts like two potentiometers in one, producing two independent wiper signals that are useful for increasing confidence in the joystick’s output in safety-critical applications. Because the joystick mounts below the panel, no gating options are offered: instead users are supposed to design their own gates in the panel itself to limit the travel of the joystick. Given that the ‘feel’ of these joysticks is important to their successful use, CH offers a number of options that modify the user interface. The joysticks are offered as standard with sprung centering, which takes a standard 1.3 N of force to push the joystick off center. A lighter spring force of 1 N, or a stronger spring force of 1.6 N, is available as an option, as is the option of a spring-less friction hold that does not center the joystick automatically.

CH Products also offers a contactless joystick, the 9000 series, which uses inductive sensing rather than a potentiometer. The joystick has a coil on its end that is fed by an oscillating current. Four coils mounted on a PCB below pick up the signal from the joystick’s coil and are interpreted by integration amplifiers to give a DC output proportional to the movement. The advantage of this approach is that the impedance of the output signal remains constant, providing simpler interfacing with no possibility of wiper noise due to track wear. Monitoring circuitry also checks the output signal against a separately generated mirror signal, so that the two separately decoded signals can be compared for consistency. If they do not match up, an error signal is generated. The parts are also available with an ‘away from center’ signal if necessary.

As with the spring choice in the potentiometer joysticks, there are also user-interface options for these contactless joysticks. One of them is ‘guided choice’, in which the joystick moves more easily towards the poles (N, S, E and W) than to other positions. The standard configuration allows the user to move the joystick anywhere using the same force, and without bias.

Sounding off

Enabling humans to tell machines what they want to do is an important part of user interface design, but so are the mechanisms the designer includes to provide feedback to the human from the machine. Again, it is easy to think of sophisticated color touchscreens as the only way to do this, but there are plenty of other options that are better suited to less sophisticated needs. How about, for example, a sounder that goes off when a task finishes, or, more importantly, a bell that rings in an emergency. In this case, subtlety is not your friend.

TDK’s PS series of piezoelectric buzzers offer a lower power alternative to electromagnetic options such as coil loudspeakers. They are available in versions that work at different frequencies, and at high sound pressure levels (of up to 75 dBA at 10 cm). They are designed to be driven by an external excitation circuit, which means that they can also be used to generate musical tones or even play back synthesized voices. Likely application areas include in kitchen ranges and computer terminals. The sounder is also available in a waterproof version, which means it can be encapsulated in the ‘potted’ circuits used in washing machines and other equipment designed for use in moist environments. If you need something more powerful, PUI Audio offers the XL-5530-LW300-S-R, a piezo sounder that produces a sound pressure level of 123 dBA at 10 cm, from a 12 V supply.

Touch

Whether you like it or not, touch control is coming to industrial machinery, driven by the user expectations that have been created by the mobile phone industry. If you cannot tap it, swipe it or pinch it, users will soon be rejecting your equipment in favor of another vendors’ that does support touch input. So how do you implement it?

One key question is whether you use resistive, surface acoustic wave, capacitive, or some other form of sensing. Each has claimed advantages, although the ‘correct’ choice will depend upon the application.

For example, IR Touch Systems offers its E series of IR touch overlays for screens from 6.4 to 24 inches on the diagonal. The company says that its technology can sense (by interpolation) 4096 x 4096 points, with a linearity error of 1.5 mm. Important for industrial interface applications, though, the company claims its touch overlay will work with a finger, gloved hand, or even an opaque object such as the end of a pen. The overlay is supplied with a USB interface, making it suitable for adding to an existing design.

Bergquist offers the 400384 five-wire 15 inch touchscreen overlay, which uses a resistive technique to sense the touch position. It says that this approach is particularly suitable for use in harsh environments. The company differentiates its approach to resistive sensing by using the stable glass layer of the overlay for both X- and Y-axis measurements, rather than using two opposing layers to create those measurements.

To make the panel work, a potential is applied across its X and Y edges alternately, with the voltage drop across the panel to the touch point being measured using a sensing connection to the top layer each time. Because the top film is only used for the sensing layer, it can tolerate resistance changes without affecting the accuracy of the measurement. Bergquist claims this approach means its panel is able to withstand temperature, humidity and mechanical stresses, and can be specified for more than 35 million activations. The panel’s work surface has also been treated to reduce glare and increase its scratch resistance.

3M, meanwhile, has developed its MicroTouch System SCT3250EX range of all-glass capacitive touch overlays. The company claims that its all-glass design makes it more transparent than resistive overlays and competing capacitive panels. As with the Bergquist panel, the 3M panel has surface coatings to increase its durability and make it suitable for use in applications such as ticketing and gaming machines, self-service and information kiosks, and healthcare displays. 3M also offers a control board, the MicroTouch Controller EX, which has a custom ASIC onboard to adapt the panel to changes in the operating environment and help keep its sensing inline with the underlying video display over the product’s lifetime.

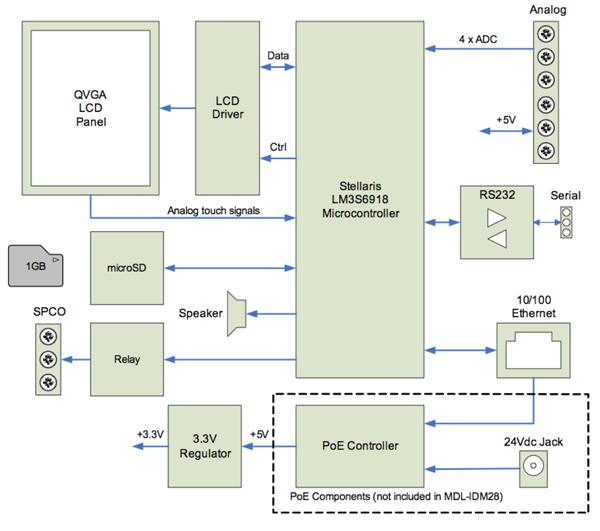

Figure 2: Texas Instruments offers an intelligent touch display module that can be powered over an Ethernet connection.

If you do not want to do the work of integrating a touch panel with a screen yourself, companies such as Texas Instruments offer intelligent display modules, such as the RDK-IDM, that do the work for you (Figure 2). The Stellaris intelligent display modules include a QVGA LCD screen with 4-wire resistive touch overlay; a 32-bit ARM based microcontroller with 256 Kbyte of main flash memory, 64 Kbyte of SRAM and 168 Kbyte of image RAM; an Ethernet connection and RS232 signals presented on a header; a MicroSD slot; four analog measurement inputs; and a relay output. The module can be powered over Ethernet, from a 24 V DC power jack, or from 5 V terminals. The module comes with full source code and design files, including a graphics library and ARM development tools. A reference design kit, including the touch panel module, a documentation CD, power supply and cables, is also available (Figure 3).

Figure 3: The Texas Instruments intelligent touch display module.

Conclusions

The interface between humans and machines is both complex and subtle. There are many ways in which humans can tell machines what they want them to do, and many ways in which a machine can provide feedback about what they are doing. The trick is to match the complexity of the part you use to the complexity of the job in hand. Interestingly, more complexity does not always mean more utility: a discrete rotary switch that outputs hard-coded hexadecimal numbers will provide a more useful input for some functions than the most sophisticated touchscreen.

When greater sophistication does mean greater utility, there are plenty of ways to achieve this, from the steadily improving utility of the various types of joysticks described above, to complete touch display modules which only need to be programmed, bringing great sophistication to your user interface. The choice is yours.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国