Design Tool Helps You Select the Right DC/DC Module for Your Application

投稿人:电子产品

2012-11-20

Although there are a number of tools available for selecting DC/DC modules, the task can be challenging given the growing complexity of converters, along with the size of the product database. Vicor, for instance, claims to offer over 100 million possible product permutations from its wide array of brick power modules and Cool-Power buck regulators.

To enable designers to pick the most appropriate converter module for their system, Vicor has readied a new DC/DC selection tool, an addition to its online PowerBench design center. Perhaps more importantly, it comes with a great feature: a simulator. That means an engineer can interactively model the electrical and thermal performance of the DC/DC converter in application-specific operating conditions and thermal environments before committing to the selected product. At the moment, however, the simulator is available only for fixed ratio converters or the IBC series.

In reality, this tool allows a user to quickly find the most appropriate DC/DC converter module from the supplier’s vast array of products and building blocks. All one has to do is to enter the essential power-related parameters such as input voltage range, output voltage range, output power in Watts or Amperes, and indicate whether isolation is required or not. The system then determines the solution that meets the user’s parameters. The designer can then select the most optimal product depending on the criteria most important to the system’s needs, such as efficiency, PCB area, power density, and so on.

DC/DC selection tool

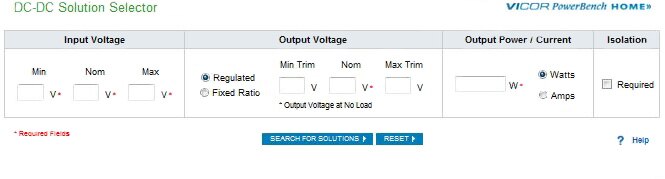

The DC/DC selection tool is part of Vicor’s PowerBench design center.¹ After you have clicked on this tool on the company website, a DC/DC Solution Selector template appears on your screen (Figure 1). Essential variables like input and output voltage requirements and output power/current needed are entered in appropriate boxes in the template. The output voltage section also gives you an option to select regulated or fixed-ratio converters, while the isolation box gives you the option to select isolated DC/DC modules.

Figure 1: Essential variables are entered in the DC/DC Solution Selector template.

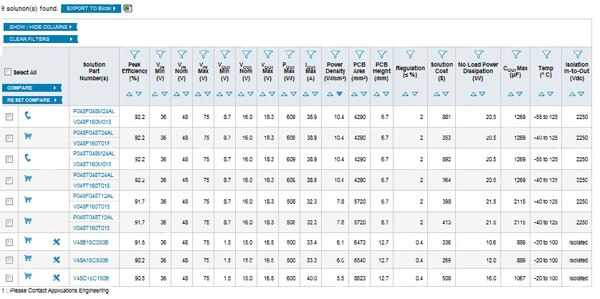

By clicking on the “Search for Solutions” button in the template after the essential variables are entered, the selection tool then picks the most appropriate parts based on the given criteria and displays them in a table format with the ability to sort, filter, and compare.

After the qualified parts are listed on your screen, the selection tool gives you the option to eliminate specification columns not important for your application. To do that, it provides a “Show/Hide Columns” button which allows you to eliminate specs that are not important to the end application.

To demonstrate its real-world use, let us plug-in some practical numbers in the DC/DC Selection tool template shown in Fig. 1. For example, let the nominal input voltage be 48 V with a range of 36 – 75 V. That means, the minimum input voltage is 36 V and maximum is 75 V. After inputting these values in the appropriate input boxes, check the regulated box in the output section and enter 12 V in the nominal output box with a range of ±2 V, so the minimum output is 10 V and maximum is 14 V. Now, say the output power required is 300 Watts with isolation. Therefore, check the isolation box to ensure that the modules recommended are all isolated solutions.

Once the “Search for Solutions” button is clicked, the tool recommends nine different part numbers with more than eighteen specs ranging from peak efficiency to input-to-output isolation, as well as cost. If the user is not interested in all of the eighteen specs, he or she can eliminate a few by clicking on the “Show/Hide Columns” button. A dialog box appears with all the electrical, mechanical and other specs checked. Uncheck the specs that are not of any interest at the present time, such as MIL-COTS, Solution type, Quantities, Package, Mounting, etc., and then click on apply.

The display in Table 1 now shows all the nine recommended parts with only the desired electrical and mechanical specs, including cost. From this display, the next step is to pick the most important criteria for your system, such as efficiency, power density, or some other spec.

Table 1: For input/output parameters entered, the table presents all the nine recommended parts with more than 18 specs, including cost.

If peak efficiency is an important performance parameter for your system, check boxes for part numbers with highest peak efficiency spec. In our case, there are four such parts with peak efficiency of 92.2%. Next click on the “Compare” button and the table displays only the selected part numbers with their respective specs, as shown in Table 2. The user can then compare the performance with cost of these recommended parts and select the most cost-effective solution for the end system.

Table 2: Only DC/DC part numbers with highest efficiency are displayed for comparison.

Option to simulate

At the present time, there is no simulation available in this tool for the regulated converters. However, if you opt for fixed-ratio converters in the output section of the tool with similar input/output voltage specs and the required power, the selection tool displays another set of parts with the option to simulate the behavior of the selected product. By the way, Vicor bus converters are fixed-ratio DC/DC converters whose input and output are directly proportional to each other, as shown in equation VOUT = K • VIN.

As an example, we will enter 48 V nominal voltage in the input voltage section of the selection tool and check fixed ratio in the output voltage section. Because the desired output is 12 V, pick ¼ as the conversion factor. You will notice that the output voltage section is automatically populated once the intended conversion factor is selected. Check the isolation box and click on the “Search for Solutions” button. A table with six qualified parts is displayed with, again, more than 18 specs. Now, by clicking on the “Show/Hide Columns” button and unchecking all undesired mechanical and other specs, Table 3 displays the result with desired specs for comparison.

Table 3: Fixed ratio IBC converters with desired specs are displayed for comparison.

To simulate a product from this table, click on the simulation icon on the left side of the table. Once the simulation is launched, the part number is displayed on the top of the page along with the reference design. For example, if you select the first part number B050E120T40N1-00 and launch the simulation tool, the page shows this part number on top along with a reference design shown in Fig. 2. This reference design includes input source and filter, DC/DC converter B050E120T40N1-00, and output filter and load. Using this reference circuit, the selection tool permits the designer to interactively model electrical and thermal performance for seven simulation types. The results are displayed graphically on screen.

Figure 2: This reference design for simulation includes input source and input filter, DC/DC converter B050E120T40N1-00 and output filter and load.

In summary, as we have shown, by expediting the selection of DC/DC converters from a vast array of product database, Vicor’s DC/DC selection tool can accelerate the design cycle in an efficient and cost effective manner.

Reference

- “DC-DC Selection Just Got Better… and Easier to Find” By Robert DeRobertis, Vicor Corp.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。