Bi-Directional DC Motor Control with DPDT Switches

2024-06-10 | By Maker.io Staff

Some applications require changing a DC motor's direction without warranting a more sophisticated DC motor controller and the additional parts that may come with it, such as a microcontroller. This article explains how to connect a motor to a single DPDT switch to build a simplistic two-way motor controller.

What is a DPDT Switch?

A DPDT (dual pole dual throw) switch is a physical toggle with two distinct positions (dual throw) and two physically separated circuits (dual pole). Since its poles are not connected internally, a dual pole switch can control up to two individual circuits at once.

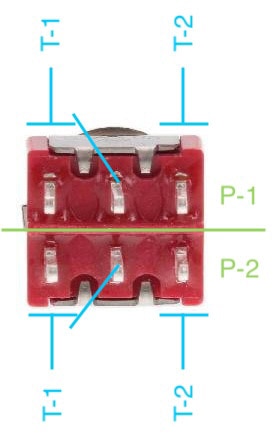

This figure illustrates the internal structure of a DPDT switch.

This figure illustrates the internal structure of a DPDT switch.

You can imagine that P-1 and P-2 are separate electrical switches with two positions (T-1 and T-2).

DPDT switches have one common pin per circuit, and the lever physically connects the two outer pins on one side to their respective center pin. So, a DPDT switch combines two standard two-way switches, connecting the outer pins to their individual common pin in the middle.

How to Control DC Motors

DC motor controllers can be very complex, and some offer numerous sophisticated features such as precise speed adjustments, regenerative braking, overheat and overvoltage protection, and many more. However, many small, low-voltage, and low-RPM motors don’t benefit from complicated controllers, especially if automated control is not required. Therefore, makers can utilize a single DPDT switch in projects that only require manually switching a motor’s direction.

When a DC motor’s pins are connected to a power source, such as a battery or power supply, the motor starts turning. Reversing the connections so that the pin previously connected to GND is now attached to the positive voltage source and vice versa reverses the motor’s direction.

Controlling DC Motor Direction with DPDT Switches

You can use a single DPDT switch to reverse the polarity of a DC motor’s pins and alter its direction without a sophisticated controller. DPDT switches have two individual circuits, each acting as a separate configuration for the motor when connected in a specific way. In each setup, one motor pin is connected to the positive voltage source, while the other connects to GND. The two paths are reversed to one another, meaning that toggling the switch changes the motor’s polarity and, thus, its direction:

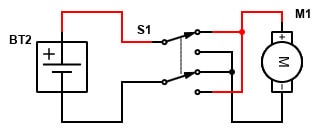

This diagram illustrates how to connect the motor to the DPDT switch and the power source. Scheme-It link

Attach the power source to the DPDT switch’s two common pins in the center. Then, connect the upper-left pin and the bottom-right one to one of the motor’s pins. Finally, bridge the top-right and the bottom-left pins of the switch and connect the two pins to the other motor pin:

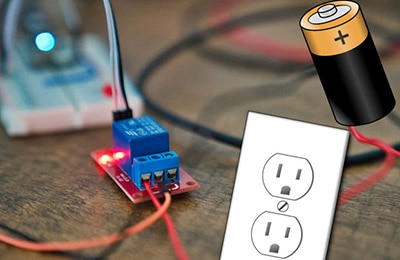

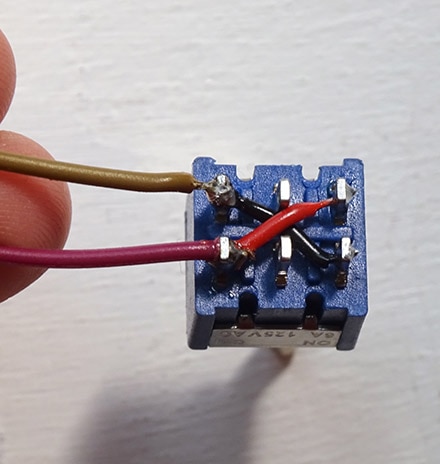

Connect the motor’s wires to the switch, as shown in this image.

Connect the motor’s wires to the switch, as shown in this image.

The power supply wires that go to the two center pins are not shown.

This simple setup requires only three components: the motor, a DPDT switch, and a power source. The caveat of this simple setup is that you can only reverse the motor's direction. You can't control the motor's speed or turn it off. However, adding a second switch introduces a third state that allows for stopping the motor.

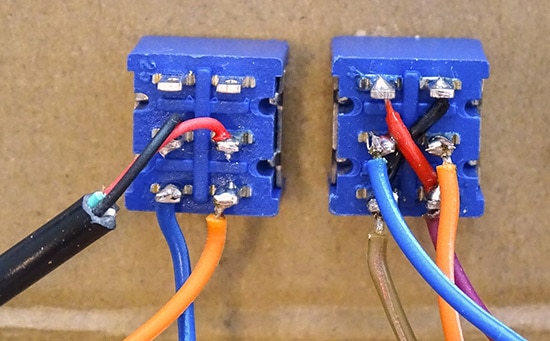

You can add a second switch that cuts power to the supply to stop the motor, as shown in this image.

You can add a second switch that cuts power to the supply to stop the motor, as shown in this image.

The left switch disconnects the power supply wires coming from the right one’s common center pins.

Each power supply wire connects to one common pin in the center of the second switch. Two new cables connect one side of the second switch to the common pins of the original DPDT toggle that controls the motor’s direction.

More Sophisticated Motor Control Methods

If your project requires automation, like changing a motor’s direction using a microcontroller, you could replace the mechanical switches with DPDT relays without changing the wiring. However, that approach still doesn’t allow modulating the motor’s speed.

Due to their simplicity, DPDT switches or relays offer limited control over the motor. However, they are cheap and can often withstand higher voltages and currents that can continuously drive much larger and more powerful DC motors, often impossible with low-cost motor controllers. Further, relays and switches don’t require cooling, as these components, unlike DC motor controller ICs, rarely get warm, even under heavy loads.

Summary

Some projects that utilize DC motors don’t need sophisticated motor controllers, especially if automated control is not required. In those cases, you can employ a standard DPDT switch to control a DC motor’s direction. A second switch that cuts the connection to the power supply allows the motor to be stopped. You can change the DPDT switches to DPDT relays to enable automated controls.

Sophisticated motor controller boards are typically more expensive than straightforward switches or relays. However, they offer features that physical switches can’t provide, such as precise speed control or regenerative braking. On the flip side, physical switches and relays can usually withstand higher voltages and currents during continuous operation, and they typically don’t heat up as much as motor controller ICs.