制造商零件编号 DEV-18387

MYOWARE 2.0 LED SHIELD

SparkFun Electronics

Embarking on a journey into the world of do-it-yourself projects is always an exciting endeavor, and today, we're diving into the realm of wearable technology with a focus on the Myo Assist Exoskeleton. Inspired by a fantastic project I found online, I want to replicate and expand upon the concept to potentially create Myo Assist Exoskeletons for other body parts, such as the elbow or foot.

After stumbling upon a fascinating project by Samuel Alexander on a Myo Assist Knee Brace, the decision was made to embark on creating a Myo Assist Exoskeleton from scratch. The first step involved gathering all the necessary components from reliable DigiKey.

A quick rundown of the essential components includes:

With the components in hand, attention turned to the 3D printing of the knee brace.

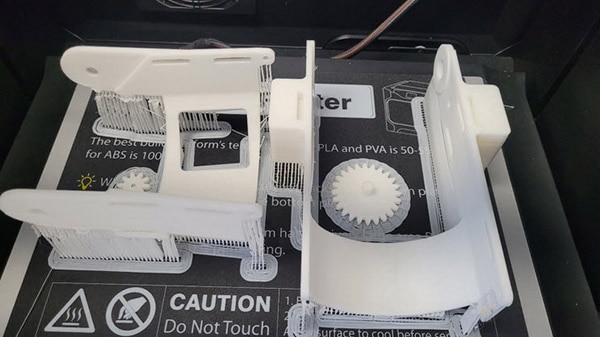

I set the printer to the highest quality setting (I wanted the braces and gears to be as smooth as possible.) After two failed prints, I rotated the parts and added extra support for adhesion to the heat plate. I preferred this orientation because the inside is smoother without any support material. In Samuel’s project, he mentioned sanding out all the excesses. I don’t know if he had a machine for sanding, but I had only some basic sandpaper and it took a lot of effort and time to remove most of the excesses.

Maybe next time I will try using Tree support as I just used the option that supports touching the hotplate.

The prints came out with minor damage, but it is very insignificant, and overall, it came out very good.

The potential success of the knee brace replication has sparked interest in expanding the project to create Myo Assist Exoskeletons for other body parts. The next target could be the elbow or foot, opening up possibilities for a full-body wearable exoskeleton. This journey into DIY wearable technology not only provides valuable hands-on experience but also opens the door to innovations that can support mobility.

Embarking on a DIY project like the Myo Assist Knee Brace is not only a rewarding experience, but also a gateway to exploring the vast world of wearable technology. As the project progresses, the potential to expand the concept to other body parts adds an exciting dimension to the journey. Stay tuned for updates on the evolution of this Myo Assist Exoskeleton project.