Walking the Path with Raspberry Pi Prototyping through Production

2020-07-08 | By Gregg Bieser

It Begins

It’s 6:30 am and I’ve started breakfast at my favorite morning restaurant... half-way through pancakes, inspiration strikes. Two hours and twenty napkins later, I’ve drawn up a complete outline of my next big thing.

Fast forward one week – I’ve completed a proof-of-concept prototype hardware plan. I hop onto DigiKey.com, order everything that I’ve spec’d, and I’m off to the races. The centerpiece of the proto design is the Raspberry Pi, which ironically has its roots in a napkin concept.

Why Pi?

I’m extremely careful when it comes to evaluating early-stage hardware since it shapes many future outcomes. Chief among these is getting the majority of the concept’s potential up-and-running as early as possible. I’ve learned in my hardware startup experience that handing a functional prototype to a team member, investor, or vendor is like magic. So, in my process, getting the most out of this early work is key.

The Pi Ticked Every Box for the Prototype

This list contains as much emphasis on maturity and diversity of software and documentation as it does on basic hardware fitness-to-task. The Pi brings both of these key characteristics to rapid-prototype development almost like magic and, as I was to learn, all the way to production (read on skeptics).

Raspberry Pi from Prototype to Production

The skeptics among you are no-doubt waving your hands and thinking, “Taking designs to prototype with Pi technologies is a great experience, but through to production? Not so easy.”

I thought so too until I met the team at Hallsten Innovations who introduced me to the Raspberry Pi Compute Module that changed my entire commercialization path and timeline. I was expecting to move away from the Pi once I moved beyond prototyping.

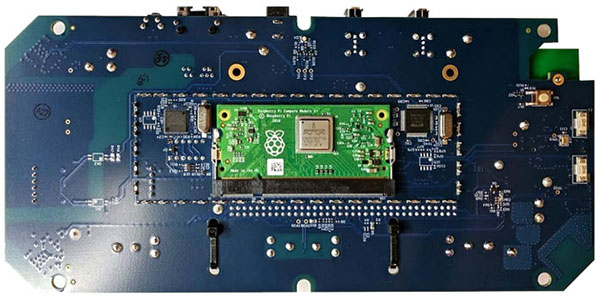

Raspberry Pi’s compute 3+ module is the heart of Hallsten Innovations Raspberry Pi Compute Module for Production. (Image source: Raspberry Pi)

The Hallsten Innovations team made me aware that it existed. Everyone in the digital electronics realm knows of Raspberry Pi technologies, but relatively few are familiar with the Compute Module. Interestingly, the Compute Module concept has been around for some time with successive versions quietly released about 9-months downstream of their maker and prototype counterparts.

The core features that make standard Pi form factors great are all accessible via a standardized 200-pin interface connector.

On-Module Features

- Fast, multi-core ARM processor with integrated GPU

- Dynamic Voltage Frequency Scaling for managing current draw/heat

- Ample RAM for Kernel and User space headroom

- eMMC flash (variable capacities)

Exposed by The Module’s Standardized Interface Connector

- Multiple UART, SPI, I2C

- A large number of GPIO

- External memory and storage interfaces

- USB Host and On-The-Go

- HDMI

- CSI camera interfaces (multi-lane)

The Hallsten team explained how the Compute Module makes napkin designs real for production use by solving key commercialization issues.

- Guaranteed Availability – in production settings, supply chain considerations are king, demanding careful selection of parts with extended longevity (how long will it be available?) and widespread distribution (how many sources drive part demand?) – the Compute Module satisfies both with Pi Foundation guarantees of availability and support for 7 years from the module release date.

- Dramatically Reduced Design Complexity – Classic “chip down” design (realization of design through the use of discrete components) can save per-unit costs, however, this method dials up complexities and often extends time-to-market. Designs incorporating the Compute Module avoid much of this risk.

- Commercialization Updates – Product updates often include increasing processing power to handle new software features. With Pi’s commitment to its 200-pin connection standard, adding this power is a snap. As new Compute Modules are released, integration is as simple as substituting the new model for the previous one.

- Industrial Operating Temperature Range – industrial operations require “military spec” thinking – all too often, you cannot just stick a standard Pi in a hardened enclosure and go. The Compute Modules -25C to +80C operating range (compare this with just 0C to 50C for the classic Pi models) make it ideal for operating in harsh environments (industrial, outdoor, tight enclosures with limited heat management, etc).

- Enclosure Friendly Footprint – at just 2.66” X 1.22” (67.6mm X 31mm), the Pi Compute Module satisfies the meta-trend of smaller-and-smaller devices.

Finally, the Hallsten Innovations team showed me several examples in which the Compute Module was used to create large-scale commercial products – one of these was especially representative of many module-centered design advantages.

Here their team created a custom SmartHome Gateway, uniting the best custom elements specific to the product (multiple radio technologies, PoE+, battery back-up, etc) with the best "off-the-shelf" production-grade processing power (yes, the Pi Compute Module), creating a "best of both worlds" hybrid design.

(Image source: Hallsten Innovations)

This real-world example sealed the deal for me.

What Does the Compute Module Do for Me?

While only you can answer that question for your tech innovation, I can relate the value to my product development path with these 5 takeaways...

1. Minimization of Fundamental Change in Existing Source Code Base – my software builds continue to target the Raspberry Pi ecosystem – this means that the port to custom hardware effort is a very focused, limited-strike exercise.

2. Shorter Time to Market – I have gone from an extended exercise in complex chip-down, multi-spin development to design of a carrier board with trimmings. Risk is down, speed is up.

3. Longevity of Design – if I need more chops, it’s likely to arrive in the updates of our Compute Module BoM SKU rather than a full redesign with related risks and implications.

4. Full Realization of Product Potential – a smaller overall device footprint means either I can fit more functionality in an existing enclosure -OR- reduce the size of the device, a key differentiator in a market that I am in the business of redefining.

5. Future-Proofing – seven years of availably and support covering 80% of our hardware design means that we’ve drastically reduced obsolescence risk, focusing it on the platform-specific elements of the product. Add in the 200 pin connector standardization, I’m golden.

Still not sure if the Raspberry Pi Compute Module should be part of your commercialization path?

The best answers come from savvy design professionals like Hallsten Innovations who have walked-the-walk using traditional chip-down methods, module-centered design, or hybrids of the two (my design) – they’ll be able to evaluate the nuances of your design specifics to best match your product and business objectives.

(Image source: Hallsten Innovations)

We’ve taken Raspberry Pi from our original 20 napkins to prototype and now, using the Compute Module, all the way through to production with concrete, measurable benefits. This model worked for us and it can work for you. So, with your napkins at the ready, enjoy some Pi (purchased at DigiKey, of course).

Related Links

“Rapid Raspberry Pi Development…including Commercialization”

https://www.hallsteninnovations.com/services-and-specialties/pi-compute-module-dev/

“Raspberry Pi Foundation: Compute Module”

https://www.raspberrypi.org/documentation/hardware/computemodule/

“DigiKey Raspberry Pi Product Page”

https://www.digikey.com/en/supplier-centers/r/raspberry-pi

“Wikipedia: Raspberry Pi”

https://en.wikipedia.org/wiki/Raspberry_Pi

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum

中国

中国