What is IIoT?

2020-02-03 | By Maker.io Staff

Industrial processes have changed dramatically since the early 1900s. The introduction of the production line helped to produce products at a faster rate, while robotics has introduced consistency and sped up production. However, a new industrial revolution is about to happen, and any obsolete production process will be at a serious disadvantage.

Pulling Information from Many Different Sources

As internet capabilities became increasingly common on different kinds of devices, engineers quickly realized that seemingly simple data sources like temperature and humidity could be used for more complex purposes. Data from multiple sensors, as well as the control of devices, could be combined into a single system that could react to sensor data to automate processes.

For example, temperature sensors can be combined with humidity sensors to control a home’s AC system to either heat up, cool down, or dehumidify the air to produce a comfortable environment. Artificial intelligence (AI) in this kind of system can take this further, by learning from user preferences and beginning to make desired changes automatically -- before the user even asks for anything to be done. However, while Internet of Things (IoT) sensors are being found in many devices, modern homes are not integrating this technology as quickly as some might have imagined.

One area is beginning to see the integration of IoT sensors and systems, however: general industrial processes.

IIoT and The Potential for AI Integration

IIoT is the Industrial Internet of Things; it’s essentially the same as IoT, but instead of being integrated into everyday devices like toasters and kettles, internet capabilities and sensors are integrated into machinery and industrial processes. Just like devices around the home, sensor data and control from internet-enabled machinery can provide far more insights into production than raw data can on its own. This data can be potentially combined and passed through a central control system that runs an AI, improving efficiency by saving materials and predicting when machinery requires maintenance or when catastrophic failures might occur.

Imagine an automated drill press station that is required to drill into metal. RPM (revolutions per minute) sensors could be used to get a readout of the RPM of the drill, which can be a direct indicator of the drill’s current health. However, an AI system may take this data further by looking at the RPM data over long periods of time to determine when the system requires maintenance. If taken further, the AI system may discover a correlation between the quality of the output and atmospheric data, therefore making adjustments to the drill’s RPM to account for these environmental factors. Suddenly, a production line can not only adjust itself to improve the quality of produced products, but it can also react dynamically to its environment and the status of each piece of equipment.

A second example would be a paper foundry which produces paper from mulch. An AI system may produce a correlation between the quality of the final paper, the water content of the mulch, and the atmospheric humidity. The production line can adjust itself depending on the humidity of the atmosphere to produce higher quality paper and therefore reduce failures and rejects.

Improving the Process for Humans and Machines

The implementation of IIoT in industrial processes may go beyond machinery itself. The integration of internet-enabled sensors and monitoring equipment into machinery can allow production lines to outsource their monitoring to third parties, or even have employees check data from their homes during critical times. Wi-Fi-enabled machinery also enables factory floor managers to remotely interface with machinery, which can help improve safety by keeping appendages away from potentially moving parts!

There are other, potentially controversial applications out there, too: IIoT systems can be used to monitor employee productivity and help managers identify individuals who deserve a bonus or a stern talking to. All of this data can be transmitted to a central station where all the gathered data can be processed and displayed to provide managers with a better overview of the production process.

IIoT: The Wave of the Future, Today?

While the IoT is a big market, the IIoT will likely be a larger market, with production lines wanting to improve efficiency, increase profits, and reduce waste. While this does come at a potential cost (with security and sensitive data concerns), there are still great, potential advantages promised by the Industrial Internet of Things!

Related Projects

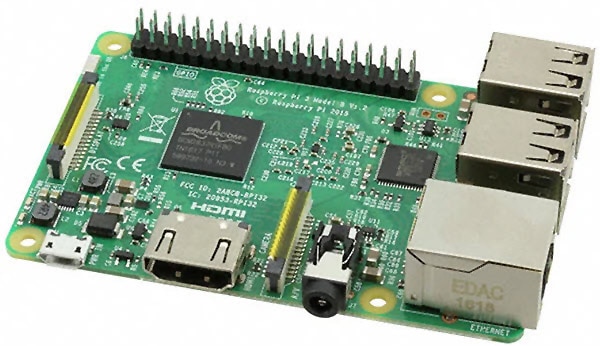

Simple Raspberry Pi IIoT Server