Module or Discrete Power Blog

This blog will discuss some of the advantages of using power modules over discrete power, highlighting the VMS-365 series and PBO-5 series from CUI. Some of the larger concepts will be size, power density, agency approvals, and other practical considerations.

Getting a product to the marketplace in as little time as possible is an age-old concept. The difference between today and years past is that there are many ways to do this more efficiently without cutting corners today. Every electronic device needs power; there is no way around this.

Some companies have the ability to dedicate a team of engineers toward finding a discrete power solution. These types of supplies can be tailored to a specific product; however, they typically come with large design costs due to the number of engineering hours involved.

- The first order of business would be to draw a schematic. Perhaps the engineer will have specific part numbers in mind at this point, but they may also need to set values on paper and find components that match that in the real world.

- After a schematic has been drawn up, then the next stage would be to move into simulation software.

- If the simulation looked good, the next step would be to start laying out a board.

- To lay out the board, there will need to be a bill of materials.

- Every component that was used on the simulation will need to be ordered for physical trial runs.

- To order these components, the engineer will need to find them on a distributor or manufacturer website, and the components will need to be in stock. Imagine the engineer who has designed a product using certain values of discrete components only to find that no one currently stocks some of the components, so the minimal ordering quantity is 10,000 pieces. There will likely be alternatives to products that are non-stocking; however, there would be no guarantee that the second component will work in the exact way that the original component worked.

- All the components would need to be vetted for where they are in their lifecycle as well. Imagine the engineer who has laid out a board with specific discrete components that are all in specific package sizes. If one of the parts goes obsolete after developing the board, the odds of finding a drop-in replacement that fits the old package size goes down. Often manufacturers will offer replacement part numbers for their obsolete products, but this is also not a guarantee.

- Once the board has been laid out and the components have been ordered the engineer can test their design.

- If all goes well the engineer can begin to think of going through an agency approval process. If the testing did not go as well as the engineer had hoped, there will need to be revisions to the design before attempting an agency approval.

Hopefully at this point the reality of what goes into discrete power is setting in. It takes a lot of time and will cost a lot of money before even getting to approval stages.

Figure 1 – VMS-365 Open Frame Module

Figure 1 – VMS-365 Open Frame Module

A solution to the problems associated with discrete power can be found in the form of power modules. Power modules are made by skilled companies that focus on power solutions. CUI is a leading manufacturer of AC-DC supplies to help the design engineer who needs a power solution. Rather than go through all of the steps that were laid out earlier, it may be prudent to consider a power module that can go into a finished product.

The medical market is one of the hardest markets to get an approval for a power supply. This is because much of the equipment either comes in direct contact with a patient or comes very close to that patient. The VMS-365 Series from CUI will be particularly attractive to the engineer tasked with powering a medical device. Figure 1 illustrates the open frame module for the VMS-365 series.

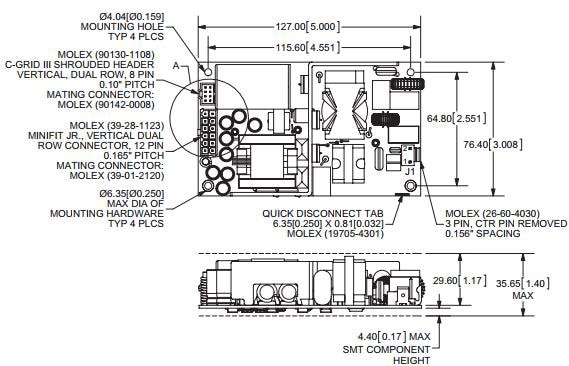

This device comes with UL 60950-1/60601-1, VDE EN60950-1/EN60601-1, CCC safety approvals. Along with the approvals, the device is RoHS compliant. The device is also optimized for space, boasting a power density of 18 W/in3, meaning every cubic inch can produce 18 watts of power. This is a chassis mount power supply so it will not have to compete with what is laid out on the board, allowing the design engineer to use more real estate on their board for critical design features. The open frame supplies for the VMS-365 series measure 5.00" x 7.00" x 1.17". Figure 2 illustrates the physical dimensions of this module.

Figure 2 – Mechanical Drawing of VMS-365 Series (Image source: CUI)

Figure 2 – Mechanical Drawing of VMS-365 Series (Image source: CUI)

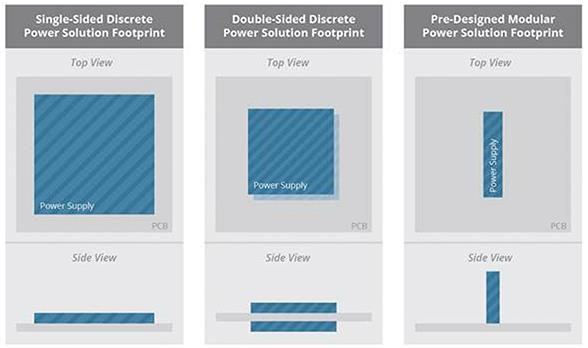

Since these power supplies are modules, they can be mounted vertically. Discrete power supplies will inherently take up board space and could end up taking space on both sides of the board. By adding a vertical board on the Z-axis, minimal amounts of space will be taken up with maximum power yield. Figure 3 demonstrates this point.

Board Space for Discrete Components vs Pre-Designed Module (Image source: CUI)

Board Space for Discrete Components vs Pre-Designed Module (Image source: CUI)

Another factor that needs to be discussed is reliability. The engineer who is tasked with creating a discrete power supply can test this to a small degree. They will ultimately be able to test a few of their products at a cost to see how well the product performs in different environments. CUI can also do such testing, but will specialize in this kind of testing. New products will not have much reliable long-term reliability data until they have been in the market for some time. Power modules will have more reliable data to draw from to understand how they are going to perform in a given environment. On the VMS-365 series datasheet there is a section in the “Safety & Compliance” table for MTBF. MTBF stands for “Mean Time Between Failures.” This will give the engineer a time frame for how long the module should last. Figure 4 shows the MTBF rating.

Figure 4 – MTBF for CUI’s VMS-365 Series (Image source: CUI)

Figure 4 – MTBF for CUI’s VMS-365 Series (Image source: CUI)

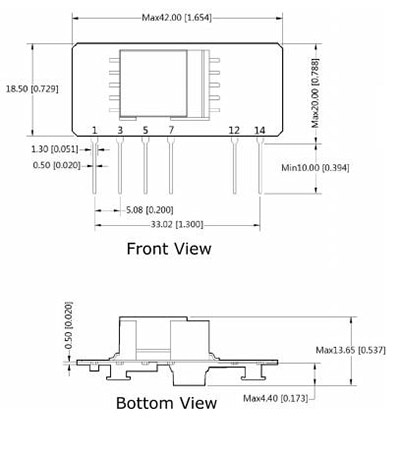

If there is a need for a power supply that is smaller than the VMS-365 series, then perhaps the PBO-5 series from CUI would be a good alternative. The same principles apply to this module regarding time savings and pre-approvals. The PBO-5 series is a good option for applications that require the power supply to be on the board. These modules are 1.65" x 0.54" x 0.79" making them ideal for products with limited space. They come in a compact SIP package that can be vertically soldered onto a board. Figures 5 and 6 illustrate the module and a dimensional drawing of the PBO-5 modules.

Figure 5 – CUI’s PBO-5 Module

Figure 5 – CUI’s PBO-5 Module

Figure 6 – Mechanical Drawing for the PBO-5 Series from CUI (Image source: CUI)

Figure 6 – Mechanical Drawing for the PBO-5 Series from CUI (Image source: CUI)

Conclusion

There are different ways to supply power to a device, and discrete power certainly has its place for many applications. While a discrete supply has the capacity to come in at a lower unit price, the startup cost will be immense. In addition to the prohibitive startup cost of using a discrete supply, there will be added time to design, source, and put all the components together and to get a design certified.

There is a solution to this problem: pre-designed power modules. While these are expensive compared to the plain discrete components, power modules can get the product to market faster, avoid time spent getting agency approvals, and take up less board space.

While it is possible to pay a team of engineers to create a discrete solution, there is already a team of engineers who have dedicated their careers to making efficient power supplies. CUI has been around since 1989 and specializes in power supplies. CUI says, “As a business we are committed to bringing the products and technologies to market that keep pace with our customer’s ever-evolving needs. Whether based on efficiency, cost-savings or flexibility, we are continually striving to innovate so our customers will benefit.”

Getting products to market quickly is not a new concept. Today, companies like CUI help to get those products to market quickly and efficiently without cutting corners.

Have questions or comments? Continue the conversation on TechForum, Digi-Key's online community and technical resource.

Visit TechForum