Thermal Performance of DC/DC Isolated Bricks

投稿人:电子产品

2013-02-19

Improvements in power supply technology, particularly in the efficiency of MOSFET switches, have allowed suppliers to improve the “power density” (power/volume) of DC/DC isolated converter brick power modules (“bricks”). Early full bricks could supply perhaps 50 W, but rapid improvements allowed half-brick designs to meet this requirement soon after. Today, 1/8 bricks can produce in excess of 200 W and even 1/16 bricks can put out up to 100 W. That means a designer can fit a smaller brick with the same power output as the previous generation’s larger device, saving printed circuit board (PCB) real estate.

However, many engineers intuitively think that employing a 1/16 brick, for example, with the same power output as an older, larger device means it is going to run hotter. That, however, is not necessarily always the case; smaller devices benefit from physical attributes that can actually make them run at the same temperature as comparable bigger converters — or even slightly cooler. This article takes a closer look at these compact power supplies.

Locating the hot spot

A DC/DC isolated converter in a fractional brick format is a self-contained, power supply module suitable for on-board use. The brick typically comprises all the components (apart from filter circuits) required for a switching power supply including MOSFET switches, energy storage components, and switching controller. (See the TechZone article “An Introduction to Board-Mounted DC/DC Converter Bricks.”)

By selecting a fractional brick, an engineer does not have to worry about the intricacies of switching power supply design. The supplier has done all the work to ensure the unit operates optimally. However, because these devices boast power densities that can exceed 7 W/cm³, they tend to generate a lot of heat. Managing that heat is one of the toughest challenges for the designer.

While a 1/16 bridge converter is delivered in a modular format, it does comprise several components, each of which dissipate different amounts of power. Figure 1 shows a 36 to 75 V input, 12 V output, 30 W 1/16 brick from Murata’s ULS Series. Note the variety of components on the module’s topside.

Figure 1: Murata 1/16 brick showing diversity of topside components.

Moreover, the power dissipation of each device varies depending on the load applied to the converter. Figure 2 shows an example of component power dissipation curves for a typical module.¹

Figure 2: Components of a brick converter dissipate power at different rates that increase with module load. (Courtesy of Lineage Power.)

The first step when comparing the thermal performance of various modules is to calculate the “apparent thermal resistance” (θA) of each. This is an estimate of the thermal resistance of the module when it is considered as a single device rather than an assembly of discrete components.

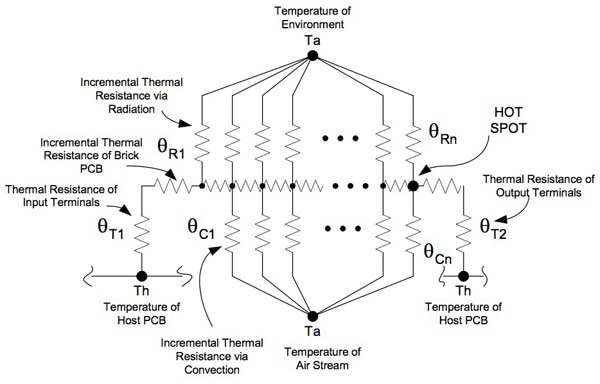

θA comprises all the parallel thermal resistances in the brick that represent heat transfer by conduction, convection, and radiation from all the heat generating sources (Figure 3).

Figure 3: Apparent thermal resistance of a power module comprises parallel thermal resistances of component parts. (Courtesy of Emerson Network Power.)

Measuring all of these parallel thermal resistances is impractical, so a more pragmatic approach is to consider a worst-case scenario by measuring probable hot spots on the module under the highest operating load likely to be applied during service. Note that while brick designers strive to distribute heat load evenly across the module, their success is influenced by space constraints, component package format, and electrical operating considerations. It is possible that a device that is dissipating a relatively small amount of power can become the hot spot and consequently the limiting factor in a brick’s apparent thermal resistance.

Once the hot spot is located, a good estimate for the apparent thermal resistance is:

θA = (TS – TE)/PD in °C/W

Where: TS is the temperature of the hotspot, TE is the surrounding air temperature, and PD is the module’s power dissipation.

It is then a simple task to estimate the temperature of the hotspot for a given load by rearranging the formula to give:

(θA x PD) + TE = TS

As we have already established a simple way to estimate the temperature of a hot spot on a power module, it is then possible to consider how the differences in dimensions between 1/8 and 1/16 bricks can actually help the smaller device stay cooler, even if it is dissipating the same power as its larger cousin.

Size matters

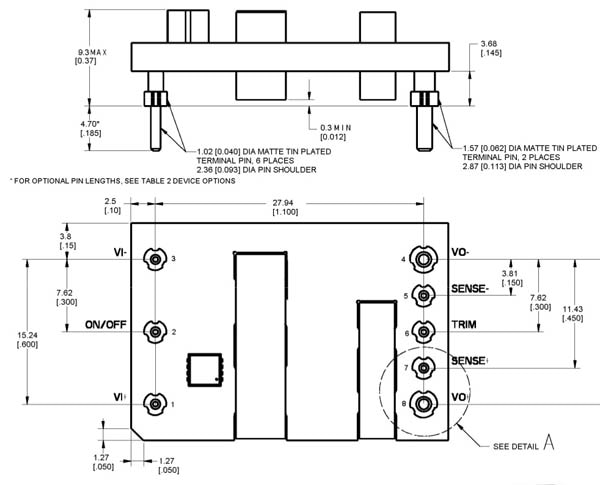

A typical 1/8 or 1/16 module adhering to the Distributed-power Open Systems Alliance (DOSA) footprint is typically mounted to the host PCB by attaching the devices’ electrical terminals at the edges of the converter to a host assembly. Figure 4 shows a schematic of GE Power Electronics’ KNW015A0F 1/16 brick power module illustrating the edge-mounted connecting pins.

Figure 4: GE Power Electronics’ 1/16 module shows the typical edge-mounted pins of a DOSA brick.

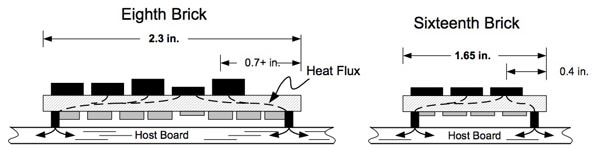

In operation, a lot of heat will be conducted through the terminals into the main PCB. Comparing a 1/8 brick to a 1/16 brick, the larger module has longer thermal paths from many of the module-mounted components to the terminals (Figure 5).

Figure 5: The shorter thermal paths of a 1/16 brick help it dissipate heat into the host board more effectively. (Courtesy of Emerson Network Power.)

Because the thermal resistance of the shorter paths to the host PCB for the hot components of a 1/16 brick is lower, the module will more effectively dissipate heat into the host PCB’s copper planes - keeping it cooler than the larger device. (There are also convection and radiation heat paths involved, so the actual picture is a little more complex.)

In addition, the 1/16 brick has less surface area then the 1/8 brick, so it will not conduct heat into the passing air stream as effectively. (One positive side effect of this phenomenon is that the cooler air from the 1/16 brick will not heat up downstream components so much.) However, a closer comparison of the devices reveals that things are again more complex. The way in which air actually passes over the module can have just as significant an effect as conduction due to the brick’s surface area.

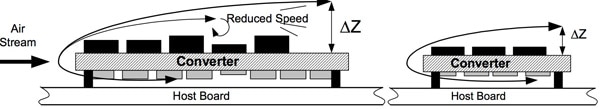

Larger bricks use higher-profile components that tend to push the moving air away from the brick substrate — while also disturbing the uniformity of flow — and reduce its effectiveness as a cooling medium. The 1/16 bricks have a lower profile, disturbing the airflow to a lesser degree and negating much of the effect of the module’s smaller surface area compared with 1/8 devices (Figure 6).²

Figure 6: Disturbed airflow of larger brick is less effective at cooling compared with smaller device. (Courtesy of Emerson Network Power.)

Efficiency equals low temperatures

If a 1/16 brick has been well designed ¬— with good heat distribution across the device and low-profile components that limit the disruption to the cooling airflow — conversion efficiency becomes the dominant factor in determining the temperature rise of an operating converter. Lower power dissipation in an efficient brick means lower temperature rise and higher usable power.

Fortunately, the latest generations of 1/16 bricks feature high efficiency. Emerson Network Power, for example, supplies its ALD15 Series 1/16 bricks, which offer up to 2.75 A at 12 V output (35 W) from a 36 to 75 VDC input range at up to 92 percent efficiency.

Similarly, Power-One supplies its SSQE48T10033 DC/DC converter in an open frame 1/16 brick format. The module again operates over an input voltage range of 36 to 75 VDC, and the company claims the unit provides a tightly regulated output voltage of 3.3 V with an output current up to 10 A (33 W). The converter operates at up to 90 percent efficiency.

For its part, Delta Product Groups provides its Delphi Series V48SH. The 1/16-brick, 48 V input, 5 V output, isolated V48SH05017NNFA, for example, provides up to 100 W. The company says the module provides up to 91 percent efficiency at full load.

Designers can take advantage of the latest generation of such high-efficiency modules to shrink the power supply circuits in their next designs while ensuring temperatures stay under control.

References:

- “Thermal Characterization Process for Open-Frame Board Mounted Power Modules,” Lineage Power application note, July 2009.

- “Thermal Design and Application of Sixteenth Brick Converters,” Geof Potter, Emerson Network Power, August 2003.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。