Taking the Measure of Photovoltaic System Output

投稿人:DigiKey 欧洲编辑

2013-10-16

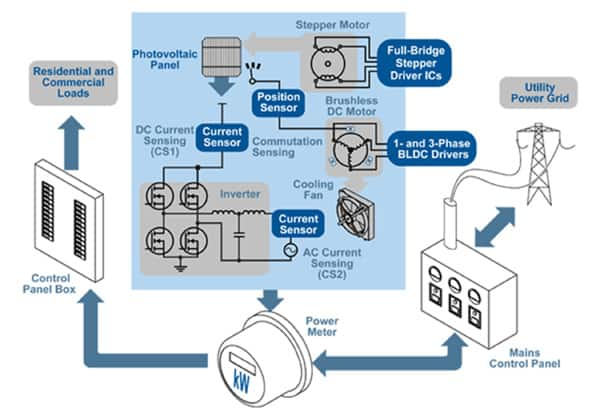

Led by solar photovoltaics, the market for harvesting energy from renewable sources is booming. At the simplest level, a single residence is equipped with a PV system, generating electricity for its own use, and feeding the excess back to the national grid. At the highest level are utility-scale PV plants and solar farms, contributing to improved grid resiliency and helping governments meet global targets to reduce CO2 emissions.

Meanwhile, the smart grid concept is emerging as the way forward to provide a much-needed upgrade to national electrical infrastructures. The deployment of smart meters and off-peak tariffs will help utilities meet peak demands without excessively increasing overall capacity. Techniques such as ‘demand response’ and ‘transactive energy’ will help us exploit renewable energy generation effectively.

The keys to the success of the smart grid are visibility, controllability, and two-way communications. Underlying these critical aspects is the need for accurate monitoring of both energy production and consumption, and the gathering of data for analysis.

At the heart of measuring and monitoring, the performance of energy generation and consumption is the current sensor. This article will consider a select number of typical devices to show how they can be used in smart meters and energy-monitoring systems connected to photovoltaic panels.

Allegro offers a range of linear Hall-Effect sensors and integrated current sensors covering a number of applications, including the output side of the PV cell inverter, and for non-intrusive measurements and monitoring alongside smart meters.

Analog Devices, a pioneer in electronic energy metering, offers its CN0241 high-side current-sensing circuit with input overvoltage protection plus an evaluation package.

Finally, the 78M6613, 78M6618, and 78M6631 AC power-monitoring SoC devices from Maxim Integrated provide an alternative approach for single- and three-phase systems, also based on current-sensing technology.

Market growth

According to analyst company Lux Research, the global solar-photovoltaic market is poised to reach $155 billion by 2018 with a CAGR of 10.5%.¹ Supply and demand is coming back into balance following a period of oversupply in 2011, which drove down prices and profits. Demand is increasing steadily, and is particularly strong in developing countries seeking to minimize their reliance on fossil fuels while creating efficient industries.

Growth in the US is dramatic too, with the current solar-system installation rate estimated at one every four minutes, according to another market research company GTM Research.² In addition, with 1 million cumulative installations forecast by 2016, the market will have grown tenfold since 2010.

Meanwhile, GTM Research predicts the global smart grid market exceeding $400 billion by 2020, growing at 8% CAGR. Smart-grid data analytics has been identified as a key and fast growing sector within this market, expected to reach $9.7 billion by 2020. It is recognized as a particularly ‘hot’ technology in Europe. Photovoltaic monitoring providers are subdivided into four categories, independent suppliers of stand-alone products, solar inverter manufacturers, integrated solar system vendors, and industrial and building management system companies.

It has been estimated by a leading European monitoring system vendor, Skytron Energy, that photovoltaic system owners who fail to monitor performance typically lose three to six percent of their potential performance efficiency. Yet the savings made in the rapid detection (and correction) of a failure is said to pay for a monitoring system in less than 2 years.

Any size of installation in the short term will benefit from a monitoring system, if only to detect cell or string failures or loss of efficiency swiftly. Longer term, the gathering and analyzing of data on performance over time and weather variations can provide valuable information on technology choices, maintenance, and equipment degradation, as well as, at the utility level, output predictions that can help planning for future growth.

Monitoring the farm…

The ability to monitor energy being produced as well as being consumed during the day is important to maximize efficiency and minimize costs, whether at the household or solar farm scale. Some level of monitoring has always been incorporated in large-scale photovoltaic installations. However, it is only recently that their potential value has been recognized. Gathering, storing, and analyzing data over a longer timescale are core to identifying true optimized performance figures. Data on failed photovoltaic modules is just as useful as data on efficient systems. Further, photovoltaic panel technology is changing rapidly, making operational data more important to measure efficiency improvements or cost savings.

Monitoring systems for solar farms today are generally highly sophisticated, and typically integrated with SCADA-like plant supervision software platforms and asset management systems. The software is typically updated regularly with new features. Environmental sensors and weather stations are incorporated to provide a record of factors such as irradiation levels, temperature, and hours of sunlight. In fact, weather data has been identified as an important input for performance-ratio planning.

Detailed data from alarm monitoring and error logs can be cross-referenced to subsystem topology and inverter model. Analytical software can make sense of the data to evaluate performance, identify routine and unplanned maintenance issues, and provide models for the future.

...monitoring the home

At the other end of the market, householders with installed photovoltaic systems can benefit just as much from a monitoring system. Not a typical feature in early installations, monitoring systems are now becoming popular retrofit devices, available from dozens of companies worldwide.

Some smart energy monitors, designed primarily for visualizing household energy consumption and used in conjunction with the new generation of smart meters, can also be configured to monitor energy generation for those with systems installed. With most new domestic photovoltaic installations, panel manufacturers and systems providers are offering monitors as part of the package.

Domestic monitoring systems typically comprise a sensor unit connected to the inverter either directly or wirelessly. A radio transmitter sends data to a display unit, which can be placed in a conveniently visible location. Depending on the sophistication of the monitor, the device can be programmed to display a range of data, including current rate of generation, the previous day’s production, revenue earned for the day, historical data, comparisons with previous time periods, and the all-important alerts if the system has stopped working. Many systems allow data to be transferred to a computer or smartphone, or to be accessible via the Internet.

At the heart of the monitoring system, whether at the solar farm or in the home, is a basic energy meter measuring the output from the photovoltaic panels. This data forms the basis for yield and performance-ratio analysis. Domestic systems typically take their measurements from current sensors or from a light sensor, which senses LED pulses from the installed system. Current sensors are considered to give a better quality reading of instantaneous power.

Current sensing

Allegro Microsystems notes that renewable energy is making up an increasing percentage of energy consumption globally, with solar and wind power leading the way. In response, the company is targeting its integrated Hall-Effect current-sensing solutions squarely at the photovoltaic and renewables market, for inverters, power conversion, and power management applications.

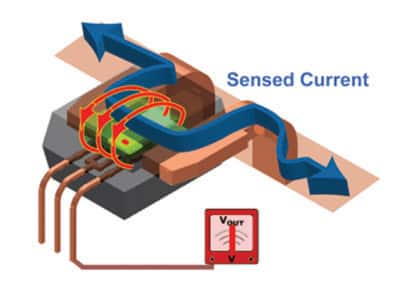

Featuring embedded high voltage isolation, the sensor ICs are suitable for DC and AC current sensing. For DC current sensing at the DC input of an inverter, devices require high isolation voltage, and high accuracy for relatively low current measurement. These Hall-Effect linear devices, featuring low noise output voltage signals, are just as applicable for AC current sensing at the output side of the inverter.

The ACS758LCB is a 100 A, bi-directional device in the 50 to 200 A range. It integrates a precision, low-offset linear Hall circuit with a copper conduction path located near the die into a single IC package. The conductor resistance is typically 100 µΩ for ultra-low power loss when sensing current up to 200 A. The package design also provides galvanic isolation to 3000 VRMS and can be used in many line-side applications.

Applied current flowing through this copper conduction path generates a magnetic field which the Hall IC converts into a proportional voltage. Device accuracy is optimized through the close proximity of the magnetic signal to the Hall transducer. A precise, proportional output voltage is provided by the low-offset, chopper-stabilized BiCmos Hall IC, which is programmed for accuracy at the factory. When used for measuring the energy generated by photovoltaic panels, accuracy is an important feature, arguably more so for domestic applications as it can be used for customer billing information.

The output of the device has a positive slope when an increasing current flows through the primary copper conduction path, which is used for current sampling. The thickness of the copper conductor allows survival of the device at high overcurrent conditions. The terminals of the conductive path are electrically isolated from the signal leads (pins 1 through 3). This allows the device to be used in applications requiring electrical isolation without the use of opto-isolators or other costly isolation techniques.

Designed primarily for AC current sensing, the 0 to 20 A ACS712ELCTR, in a flip-chip package, features much of the same design structure and operational characteristics. Differences include the internal resistance of the conductive path, which is 1.2 mΩ, and this device can survive up to five times overcurrent conditions. An evaluation board, the ASEK712ELC-20A-T-DK, is available.

High-side current monitoring

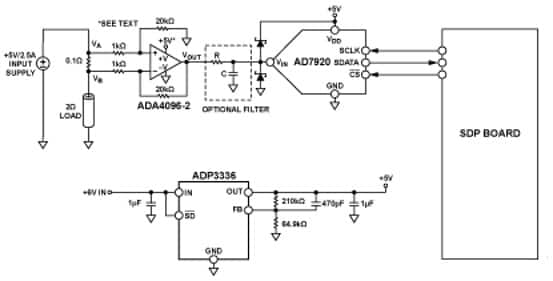

Analog Devices supports a wide range of metering applications with various devices for metrology, isolation, power management, and communications functions. The CN0241 is a high-side current-monitoring solution with input overvoltage protection. To save power, the current-sensing circuit can be powered down, yet allows the power source, such as a solar panel, to continue to operate. A simplified schematic is shown in Figure 5. A detailed Circuit Note³ explaining circuit functions and benefits is available.

The current monitor incorporates the ADA4096-2 op amp connected as a difference amplifier to monitor the high-side current, the ADP3336 low dropout (LDO) linear regulator to power the circuit, and the AD7920 12-bit successive approximation analog-to-digital converter. A single sense resistor is included together with four additional resistors to set the difference amplifier gain.

The op amp has input overvoltage protection, without phase reversal or latch up, for voltages of 32 V higher and lower than the supply rails. The Circuit Note explains that this is especially important in applications with power-supply sequencing issues that could cause the signal source to be active before the supplies to the amplifier are applied.

The 500 mA LDO has the option of accepting an input voltage range from 5.2 to 12 V when set for a 5 V output. It can also be used to supply power to other parts of the system. Both the op amp and the LDO regulator can be powered down if necessary.

A slight modification to the circuit enables the CN0241 to monitor the current for input supply voltages up to +30 V. Instead of connecting the +V pin of the op amp to the +5 V from the LDO, the +V pin is connected directly to the input supply being monitored. In this configuration, the ADA4096-2 is powered directly from the input supply.

For circuit evaluation and test, the EVAL-CN0241-SDPZ circuit board is used in conjunction with the EVAL-SDP-CB1Z system demonstration platform. The SDP controller board is set up using the CN0241 evaluation software, to capture the data from the current-sensing monitor circuit.

Status insight

Maxim Integrated meanwhile, points out that accurately measuring the energy produced from solar photovoltaic installations provides valuable insight into the status of system operation. As renewable power becomes a greater percentage of power on grids, Maxim states utilities will rely on the accuracy and speed of these energy measurements to maintain power delivery while smoothly integrating variable sources.

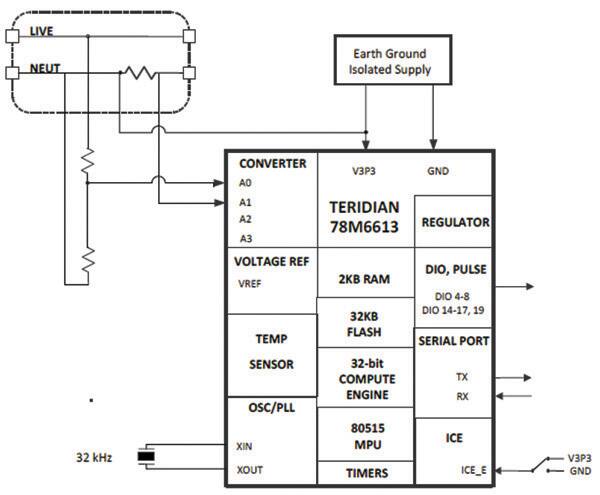

The key solutions offered from Maxim are the 78M6613 single-phase AC power measurement IC for residential monitoring systems, the 78M6618 8-channel version for larger scale operations with multiple points of measurement, and the 78M6631 three-phase power measurement and monitoring SoC for commercial systems.

The 78M6613 features four analog inputs for interfacing to voltage and current sensors. Measurements are fed to the integrated 32-bit compute engine via the Teridian Single-Converter Technology (see Figure 6), comprising a 22-bit delta-sigma analog-to-digital converter and multiplexer. The incorporation of digital temperature compensation and precision voltage references contribute to the better than 0.5% measurement accuracy over a wide 2000:1 dynamic range. The accuracy and range of these devices allow energy producers to monitor and gauge the system performance of rooftop solar panels even in the weakest sunshine.

An additional 8-bit MPU core with 2 kB Xram and 32 kB Flash, 32 kHz time base with hardware watchdog timer, UART interface, and 10 GPIO pins complete the configuration. An array of in-circuit emulation and development tools, plus application firmware is available to provide a turnkey energy-measurement solution optimized for AC power supply units and for high power-load (split phase) units.

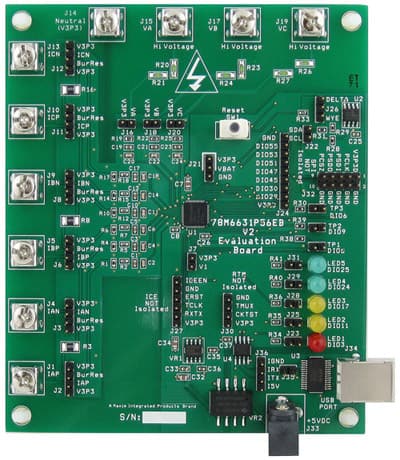

Evaluation boards for all the devices are also available. The 78M6631-EVM-1 connects to a PC through a USB cable and the on-board 78M6631 is preprogrammed with demonstration firmware code. An in-circuit emulator adaptor and three current transformers are included.

Summary

From roof-top panels to utility-scale solar farms, monitoring the performance of photovoltaic panels is essential, and is consequently a fast-growing market sector. Current sensing and measurement is the core technology behind most energy monitoring systems. A small number of typical circuits have been used to illustrate the technology, covering AC and DC measurements, featuring high-side current monitoring, high accuracy, wide dynamic range, overvoltage and overcurrent protection, and low power operation.

Case study: combining smart monitoring and energy harvesting to take people out of fuel poverty

Nearly 16 million US households (over 7%) live in fuel poverty, where they need to spend over 10% of their annual income on energy bills. In the UK, this proportion is even higher with 3.2 million households (over 12%) in fuel poverty.

By using a range of off-the-shelf energy monitoring tools coupled with energy-harvesting technologies, a social housing community on the Isle of White, UK, has been able to reduce the number of those in energy poverty.

The initial plan: electricity but no monitoring

The Chale Project started as a very basic attempt to cut the energy bills of some of the poorest members of the community. All the houses were electrically heated and to cut this, the local government had raised funds to retrofit the houses with solar panels and air-source heat pumps.

This led to slight improvements for the families, but without smart metering equipment, the people were not able to adjust their behavior to take better advantage of the free power. The community therefore turned to IBM's Andy Stamford-Clarke, another Chale resident who had retrofitted his 15th century thatched cottage into a house that could announce over Twitter if there was a leak, if a bulb had blown, if it was using too much power, and even if a mouse trap had fired.

The equipment

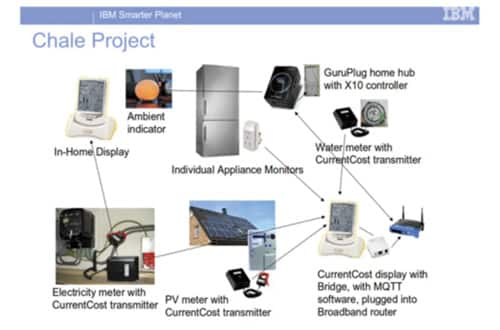

Each house incorporated an electricity meter, a photovoltaic meter, and water meter, all with current cost transmitters. In addition, six individual appliance monitors were also fitted to the devices that used the most power.

They all stream data to a current cost display running MQTT software and connected to a broadband router. Finally, to make it easier to know when power consumption exceeds power generation, a multicolor LED ambient indicator was also used, controlled by a GuruPlug home hub with X10 controller.

The effects

It quickly became apparent that the photovoltaic panels were not providing enough energy to power all appliances simultaneously. It was also shown that only small changes were needed, for example running the washing machine and tumble dryer consecutively, rather than at the same time, brought the power demands below the solar threshold.

In total, energy bills were roughly halved. More importantly, anecdotal evidence also suggests that crime has declined on the estate as a result and that the occurrence of renters owing back-rent has decreased.

References:

- Lux Research, Solar PV ‘Market Size’ report

- GTM Research, US Solar and Global PV Monitoring reports

- Analog Devices CN0241 Circuit Note

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。