Power Modules Underpin Smart Grid Adoption

投稿人:电子产品

2015-12-10

The century-old U.S. electricity grid is said to be the largest interconnected machine on Earth. The grid comprises more than 9,200 generating units producing over 1,000 GW and connected to more than 480,000 km of transmission lines. However, at no time in its history has this grid undergone such rapid change as that which is happening now.

Utilities are investing heavily in “smart grids” to dramatically enhance energy delivery by lowering costs, improving efficiency, offering customers more flexibility, and making the connecting of renewable energy sources easier.

Implementing smart grids demands a range of new technologies including grid protection, power quality enhancement, fast communications, cyber security, and consumer monitoring. That makes these huge machines increasingly reliant on the electronic components that have supported the technology revolution already experienced by many other sectors.

This article looks at the opportunities that are opening up for electronics designers as smart grids gather pace and then describes a range of modules from major suppliers that have been specifically designed to power the electronic systems, satisfying the unique challenges of these new electricity networks.

Power revolution

The smart-grid revolution has been triggered by a number of factors, including consumer backlash to rising prices, increased raw-energy costs, deregulation, and pressure from the environmental lobby to limit the construction of new fossil-fuel power stations. The disruption is bringing computerization, digital communication, and bi-directional energy flow to a previously ultra-conservative industry in order to dramatically enhance the performance of its networks.

While the smart grid is complex, it can be broken down into four key areas: Infrastructure, communications, metering, and renewable energy.

Engineers tasked with upgrading existing infrastructure to smart-grid status are in turn concerned with protection, monitoring, and power quality. Apart from the wires and poles, that infrastructure comprises “distribution automation” resources equipped with sensors to gather data, sending information about the grid’s status and performance to the utility’s network operations center to allow operators to adjust and control assets from the central location. In addition, smart grids automatically monitor, protect, and optimize electricity distribution to industrial users and domestic consumers. The built-in intelligence of smart grids also allows rapid automatic intervention in the case of faults, limiting outage duration.

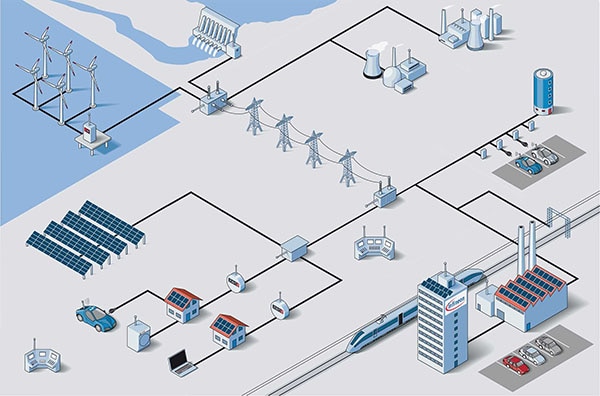

Another key difference between a smart grid and a conventional network is that electricity flows in both directions, which enables utilities to move away from centralized power generation and encourage distributed renewable energy sources such as wind turbines and photovoltaic (PV) panels on domestic consumers’ roofs (Figure 1). Smart grids also limit system losses, thus improving overall efficiency and helping to decrease the generation of carbon emissions and other pollutants[1].

Figure 1: Smart grids will feature conventional and diversified electricity generation. (Courtesy of Infineon)

Smart-grid information systems include Power Line Communications (PLC), Ethernet networks, serial links, and various wireless technologies including ZigBee, 6LoWPAN, and sub-1 GHz connectivity.

Consumers tend to associate smart grids with smart meters––home-monitoring devices that can provide the consumer with fine-grained data about usage trends––allowing them to modify consumption to, for example, take advantage of cheaper tariffs and allow utilities to smooth demand peaks. However, smart-grid metering comprises much more than the individual devices outside of homes, factories, and offices. Advanced-metering infrastructure (AMI) provides the two-way communications necessary for utilities to automate billing, remotely connect/disconnect individual meters, and implement demand-response programs. AMI networks also provide the ability for real-time monitoring of grid operations and immediate notification of outages to accelerate utilities’ response.

What is more, renewable energy is a major challenge as generation extends beyond hydroelectricity and wind farms to “microgrids” comprising groups of households feeding power back into the network from solar panels. The inverter is a critical component responsible for the control of electricity flow between the PV cells making up the panel and the power grid. The challenge for engineers is how to do this in an efficient, reliable, and cost-effective manner[2].

In the U.S., ten states––including California, Florida, New York, Pennsylvania, and Texas––are leading the national effort to deploy the country’s smart grid. Together, these states have already been the recipients of $1.9 billion of the $4.5 billion earmarked in the American Recovery and Reinvestment Act for investment in the smart grid.

This momentum is set to increase and is fueling demand for the electronics that are the foundation of many smart-grid systems. Silicon vendors have reacted by developing a range of components that enable electronic engineers to design products that underpin smart-grid applications; and each of these products demands a power supply uniquely matched to the exacting demands of intelligent electricity distribution.

Reacting to outages

Apart from efficiency improvements, the key advantage of a smart grid is its ability to recover from faults caused by factors such as lightning, high winds, or falling tree branches. Utilities are understandably keen to prevent catastrophic failures such as the Northeast blackout of 2003. This was a widespread power outage that affected an estimated 10 million people in Ontario, Canada and 45 million people in eight U.S. states. Some people were without power for two days.

Smart grids incorporate protection devices such as circuit breakers, which cut the supply when they detect anomalous events such as excess current or voltage. By establishing the location of the fault and taking advantage of the bi-directional energy flows enabled by a smart grid, utilities can isolate the small section of distribution line where the fault has occurred while using alternative lines to quickly restore power to the rest of the grid.

Many of these protection devices depend on power supplies from major semiconductor companies. Texas Instruments (TI), for example, offers a small form-factor, 12 W power supply reference design to power the protection relays used in smart-grid circuit breakers (Figure 2).

The design is notable because it is able to handle a wide range of both AC and DC inputs (24 to 250 VDC or 88 to 276 VAC) and provides a 15 V, 800 mA (12 W) output from a 100 by 100 mm form factor (making the power supply suitable for protection relays that have to be housed in compact housings).

Figure 2: Wide-input-range power supply reference design for protection relays from Texas Instruments.

The power supply uses a two-stage converter topology comprising a DC-to-DC step-up (“boost”) regulator designed around a TI TPS40120 current-mode controller which forms the input to a quasi-resonant flyback converter designed around a UCC28740 pulse-width-modulation (PWM) controller. The output of the flyback converter forms the 15 V, 0.8 A output from the power supply.

Enabling interoperability

In conventional electricity distribution grids, infrastructure is operated in isolation and without gathering any information about grid performance or the cause of faults. Full implementation of a smart grid requires these “dumb” devices to be replaced with Intelligent Electronic Devices (IED). In addition to performing essential electrical tasks such as transforming voltages, redirecting energy flows, and isolating sections of the grid in the event of faults, IEDs constantly monitor voltages, currents, power quality, and other parameters that can affect grid performance.

This information is passed between IEDs (such that they can be automatically activated to correct abnormal grid operation) and back to operators (who can then quickly respond to peaks and troughs in demand or outages) via dedicated communication channels. These communication channels provide rapid and reliable transmission of information and rely on wired- and wireless-technology and Internet, Ethernet, industry standard, and proprietary protocols.

The electricity distribution industry is working hard to adopt a communications standard to enable interoperability between the disparate elements of an electricity grid. The favored standard is IEC 61850, which is already established for communications in electrical substations. IEC 61850 is now being extended beyond the substation to the Intelligent Electronic Devices (IED) that make up smart grids.

IEC 61850’s strength is its ability to rapidly exchange data yet preserve the original meaning of the information. As such, the standard promises to markedly enhance communication between, and coordination of, smart-grid infrastructure.

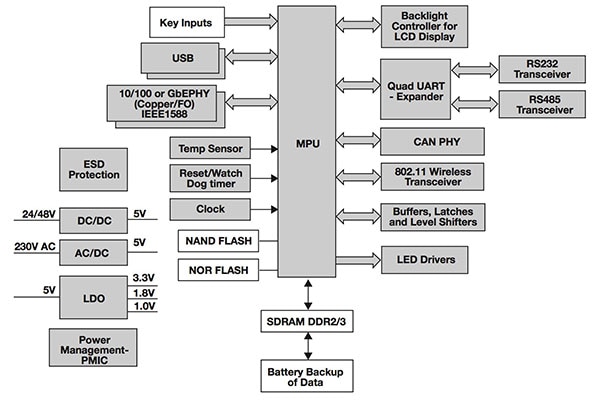

The IEC 61850 Gateway forms a key part of this communication system and again TI has stepped in with chips designed to make the power supply for these products easier to develop. The gateway will likely require multiple power-management chips to deal with multiple AC and DC inputs. Figure 3 shows a schematic with a selection of voltage converters including a 24/48 VDC input/5 VDC output switching regulator, a 230 VAC input/5 VDC output switching regulator and 5 VDC input/multiple DC output low-drop-out linear regulator (LDO).

Figure 3: Schematic for IEC 61850 Gateway illustrates requirement for multiple-voltage regulators. (Courtesy of Texas Instruments)

Another option for gateway power is a power management IC (PMIC) such as the TI TPS69510. The PMIC can accept 5 V Li-ion battery power and provides three step-down (“buck”) converters, one boost converter, and eight LDOs, and is designed to support the specific power requirements of OMAP-based applications.

The eight general-purpose LDOs power the OMAP-based processors, power to other devices in the system, and power to DDR memory supplies in applications requiring these memories.

Managing consumption

Consumers become familiar with the concept of smart grids when utility maintenance crews arrive at their home to replace antiquated meters with intelligent units. According to the U.S. Energy Information Administration (EIA), by 2013 (the latest year for which numbers are available) U.S. electric utilities had installed 51,924,502 smart meters of which 89 percent were in residential customer installations.

Smart meters are more than just monitoring units that can be interrogated remotely. A key advantage of these intelligent devices is the supply of information that allows both utilities and consumers to manage supply and demand. Utilities are able to use the information to precisely determine peaks in demand and reserve generating capacity for similar future peaks. The utility can also set “dynamic” tariffs, reflecting the costs (and carbon content) of generation and distribution at any particular time, or rewarding consumers for using electricity at times when renewable sources are producing a lot of power.

Consumers could even opt for packages that allow appliances to be turned on and off automatically by the grid operator to help maintain virtually a second-by-second balance between supply and demand.

A downside of smart meters is the requirement for them to be “always on.” Each unit draws relatively little current, but the combined effect of millions is significant. The silicon vendors have responded by cutting the quiescent current of their high-voltage power solutions for these always-on, non-isolated systems for applications such as smart meters.

Several manufacturers offer AC-to-DC voltage regulators that meet the tough demands of smart metering. For example, STMicroelectronics supplies a power supply module, the VIPER06, that can operate from an 85 V to 265 VAC input and features an 800 V power metal-oxide semiconductor field-effect transistor (MOSFET). The chip can output up to 8 W yet consumes just a few hundred microamps quiescent current.

For its part, TI has recently introduced the UCC28880, an AC-to-DC switching regulator for smart-meter applications. The UCC28880 integrates the controller and a 700 V power MOSFET into one device. The chip also integrates a high-voltage current source, enabling start-up and operation directly from the rectified mains voltage.

The quiescent current of the device is less than 100 µA, improving the efficiency of the solution. TI says that by using the UCC28880 engineers can design most common regulator topologies using a minimum number of external components.

Utilities have also implemented “concentrators” as part of their smart-metering systems. Concentrators gather information from a group of smart meters (for example, those in a single apartment block) and aggregate and analyze the data before transmitting it wirelessly or via a power line modem to the utility. Concentrators can also be used to send information from the central control facility back to the smart-meter group and facilitate maintenance functions such as software updates.

In addition to supplying power modules for smart meters, STMicroelectronics also caters for the power requirements of concentrators. The power requirements for concentrators are similar to those for smart meters, although a little more demanding due the additional computation performed by the unit.

STMicroelectronics promotes the Altair 04-900 AC-to-DC switching voltage regulator for concentrator applications. It is based on a quasi-resonant flyback topology and is capable of operating from a mains input and features a 900 V breakdown power stage. The Altair features low-standby consumption (around 1 mA) and overcurrent protection to safeguard against transformer saturation and secondary diode short circuiting. The company also provides a power supply reference design for smart-metering applications, under the part number STEVAL-ISA105V1 (Figure 4).

Figure 4: STMicroelectronics power supply reference design for smart-metering applications.

Huge rewards

Modernizing decades-old electricity infrastructure with computerization and communications technology in the U.S. and the rest of the developed world is a huge task. The cost of the exercise will run into billions of dollars without even factoring in disruption to customers as sections of the grid are upgraded.

However, the rewards are great. A smart grid will dramatically improve the efficiency of the electricity system by reducing system losses, make it easier to switch in renewable energy sources (thus reducing the requirement for “base load” – fossil-fuel generating capacity that must be kept running permanently to cope with anticipated peaks), and enable utilities to encourage consumers to reduce consumption through flexible tariffs. Higher efficiency and greater contributions from renewable sources also helps authorities meet their commitments to reduce carbon emissions.

Smart grids also limit disruption caused by outages by allowing operators to quickly isolate faults and re-route power to as many consumers as possible while the problem is rectified.

The success of smart grids will rely heavily on novel silicon and innovative design engineers; and those products will in turn rely on specialized power modules that meet the particular requirements of smart- grid application such as wide-input voltage ranges and low-quiescent currents. The good news is that there are already many integrated solutions commercially available for engineers looking to take a slice of this lucrative market sector.

For more information about the parts discussed in this article, use the links provided to access product pages on the DigiKey website.

References:

- “Carbon Emission Reductions by the Implementation of a Smart Grid,” Steven Keeping, NOJA Power, 2013.

- “Smart Grid & Energy Solutions Guide,” Texas Instruments, 2015.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。