Power Management ICs for Micro-harvesting Designs

投稿人:电子产品

2012-01-18

Micro-harvesting, or scavenging of energy from ambient sources in the environment, offers new opportunities for powering circuits in diverse embedded applications. For engineers, however, high variability in energy availability dictates a need to address requirements for effective power management to accommodate stringent power budgets and peak demands in these circuits, as well as manage energy-storage devices. Effective solutions can be found via a class of highly efficient devices from silicon manufacturers including Advanced Linear Devices, Cymbet, Linear Technology, Maxim Integrated Products, and Texas Instruments.

Energy sources

Micro-harvesting places unique requirements on circuit designers. Ambient energy sources are inconstant, providing miniscule amounts of energy at best (Fig. 1). Engineers cannot assume that power is available on demand from these sources. Even when power is available, ambient sources cannot always meet the peak power requirements of even low-power applications.

|

Energy Source |

Harvested Power |

|

Vibration/Motion |

|

|

Human |

4 μW/cm² |

|

Industry |

100 μW/cm² |

|

Temperature Difference |

|

|

Human |

25 μW/cm² |

|

Industry |

1-10 mW/cm² |

|

Light |

|

|

Indoor |

10 μW/cm² |

|

Outdoor |

10 mW/cm² |

|

RF |

|

|

GSM |

0.1 μW/cm² |

|

WiFi |

0.001 mW/cm² |

Figure 1: Micro-harvesting requires efficient power management because ambient sources can be highly variable power sources, providing miniscule amounts of energy. (Courtesy of Texas Instruments)

One of the implications of the self-powered approach used in micro-harvesting is that power might not be available even to start up a circuit if the energy source has been dormant for too long a period of time. As a result, micro-harvesting designs need to account for "cold-start" capability, where circuits bootstrap the initialization process, powered initially only by the ambient source until sufficient power is available to energize the entire circuit, often by switching on individual sub-circuits in a carefully designed startup sequence.

Typically, these designs will include specialized, low-self-discharge storage cells or ultracapacitors that not only help bootstrap the cold-start process, but also provide the required reservoir of energy needed to support peak power demands. In turn, power management circuits must be able to manage efficient charge and discharge cycles for energy-storage devices. In the case of thin-film batteries, these circuits must be able to manage charge state carefully to prevent damage to these batteries.

Power management devices for micro-harvesting must impose minimal power requirements themselves. As with the rest of the components in a micro-harvesting-powered design, power management devices must exhibit ultra-low leakage current during standby operation, while providing rapid turn-on times to avoid energy-wasting startup time and to help minimize overall active duty cycle.

On the front end, power management circuits need to maximize power-transfer efficiency from the energy transducer by matching and maintaining transducer output impedance. For many types of transducers, such as piezoelectric devices and thermoelectric generators, output impedance is constant, but for photovoltaic (PV) cells, output impedance falls with increasing light intensity. For solar applications, maximum efficiency requires maintaining PV cell output impedance at a characteristic value in a process called maximum power point tracking (MPPT). (For further information see, for example, the TechZone articles “Variables to Consider when Designing Solar Power Applications” and “Microinverters Improve Efficiency”).

Input boost

In many micro-harvesting applications, transducers operate at levels below the minimum input voltage or current requirements of most power conditioning devices, including conventional step-up converters and charge pumps. In these cases, engineers can opt for specialized very low-voltage input boost devices such as the Advanced Linear Devices EH4200 series, Linear Technology’s LTC3108/LTC3109, or Texas Instruments’ BQ25504.

Designed to produce AC output from very low energy sources, the ALD EH4205 and EH4295 Micropower step-up low voltage booster modules use an on-board transformer that couples to a dedicated MOSFET array to form a self-starting oscillation circuit. At 80 mV for the EH4205 or 70 mV for the EH4295, the on-board oscillator is energized to produce an AC output that can be used directly or passed through a full-wave bridge rectifier to produce DC output for driving custom circuits or for charging batteries or supercapacitors. The output of the ALD EH4200 series modules can also drive ALD's EH30x (EH300, EH301) energy harvesting modules. Designed to scavenge ambient energy from diverse continuous or intermittent sources, these always-on modules can function with instantaneous input voltages ranging from 0.0 V to +/-500 V AC or DC, and input currents from 200 nA to 400 mA.

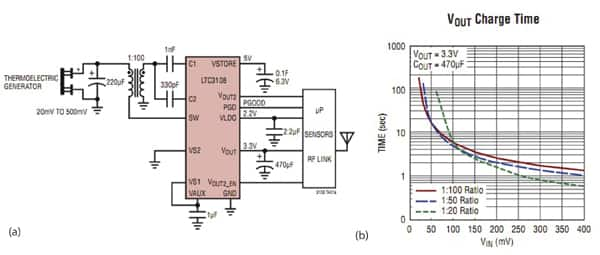

The Linear LTC3108 is a DC/DC converter designed specifically to harvest energy from extremely low input voltage sources. The LTC3108 features a MOSFET resonant step-up oscillator that allows it to use input voltages as low as 20 mV to power circuits or charge external storage components with a minimum number of external components (Fig. 2). The device is designed to provide multiple voltage outputs in micro-harvesting applications. It provides a regulated 2.2 V output from its internal low-current low dropout (LDO) linear regulator, as well as selectable output voltage at 2.35 V, 3.3 V, 4.1 V, or 5 V. An additional voltage output can be used to charge an external storage capacitor or battery.

Figure 2: The Linear LTC3108 (a) can provide Vout to charge external components with input voltage as low as 20 mV (b). (Courtesy of Linear Technology)

The TI BQ25504 boost charger IC operates with input voltages down to 80 mV and requires less than 330 nA quiescent current. The device uses pulse frequency modulation (PFM) to maintain the input voltage at the selectable threshold voltage level -- used in the device's MPPT support features. The device offers battery protection features that allow engineers to program specific thresholds for under voltage, over voltage, and good battery levels to prevent excessive depletion or excessive charging of sensitive storage elements. The BQ25504 also includes a thermal shutdown feature designed to help protect rechargeable Li-ion batteries.

Other solutions

Other energy harvesting applications with less stringent requirements for transducer output voltage can take advantage of specialized power management devices from Cymbet, Linear, and Maxim Integrated Products.

The Cymbet CBC915-ACA extends support for MPPT with an active tracking feature designed to match the output characteristics of input transducers including photovoltaic, electromagnetic, piezoelectric, and thermoelectric generators. Engineers can elect to drive the device into MPPT mode during initial power up or later through programmed command. In this mode, the device begins adjusting the input boost converter impedance to match the output impedance of the PV cell or other transducer.

The Linear LTC3588-1 Piezoelectric Energy Harvesting Power Supply IC uses a built-in full-wave bridge rectifier and high-efficiency buck converter to maximize energy output from piezo devices. The device interfaces directly with the piezo device, using the piezo's AC output to charge an external capacitor on the input. The buck converter maintains a regulated output voltage by transferring charge from this input capacitor to an output capacitor. The LTC3588-1 features an undervoltage lockout mode that disables the buck converter when the input capacitor is depleted, allowing energy to accumulate more efficiently from the piezoelectric transducer onto the input capacitor.

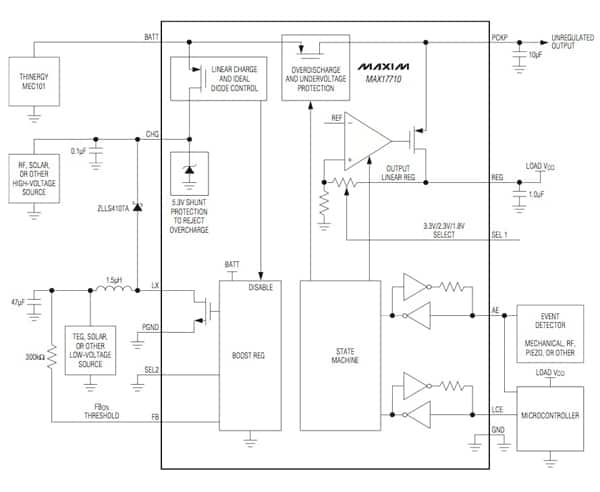

The Maxim MAX17710 Energy-Harvesting Charger and Protector similarly offers critical battery protection features along with LDO regulated voltage outputs (Fig. 3). The device includes a boost converter that can operate in pulsed mode to harvest energy down to about 1 μW or operate in continuous mode to work with energy sources up to 100 mW.

Figure 3: The Maxim MAX17710 offers battery protection modes and a boost converter that enables energy harvesting down to 1 μW. LDO control signals AE and LCE enable efficient load control and battery management. (Courtesy of Maxim Integrated Products).

Micro-harvesting presents a broad range of unique requirements for power management of input sources and energy storage devices. Not only must power management circuits accommodate impedance requirements and output voltage limitations of energy transducers, these circuits must support energy storage by providing capabilities to manage over-voltage and under-voltage conditions that can damage energy storage devices. Engineers can take advantage of a class of specialized power management devices tuned to the unique requirements of micro-harvesting and designed to speed development of more innovative designs powered by energy harvested from ambient sources.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国