LEDs in the Home: Challenges and Opportunities

投稿人:电子产品

2012-11-27

Light-emitting diodes (LEDs) are immensely popular, and there is little question both inside and outside of the SSL industry that it is the best lighting technology available today. The superiority of LEDs compared to other types of lighting start with its dramatic advantages in energy efficiency and operating life. LED light bulbs can deliver approximately the equivalent amount of light of traditional incandescent and fluorescent lighting, while consuming as little as one-third the energy. LED bulbs also promise to last more than 20 times longer than products based on more mature lighting technologies. What’s more, the solid-state components of LED bulbs offer better protection against mechanical damage than the relatively fragile traditional lighting technologies. Taken together, these characteristics offer users of LED lighting solutions a highly attractive ROI, particularly in commercial and industrial applications where maintenance and bulb replacement is difficult and/or expensive.

For all of these reasons the U.S. Department of Energy has estimated that by 2030, the adoption of solid-state LED lighting will reduce lighting electricity consumed in the nation by one-fourth, equaling approximately 190 terawatt-hours and $15 billion, while reducing carbon gas emissions equivalent to 21 million cars.

Unfortunately, residential users do not care quite as much about these advantages as commercial users. While they may want LEDs, they want them at a competitive price and they are in no hurry to buy LED lighting products that are still priced two- to three-times higher than compact fluorescent lamps and are much more expensive than a six-pack of incandescent lamps, which will cost them about $8.

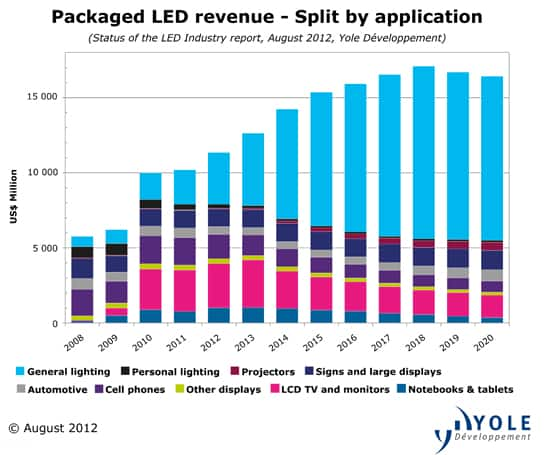

Research confirms that LEDs are used in a plethora of applications. For example, Fig. 1 shows many of the places you will see LEDs (note especially general lighting). But what it does not tell you is how residential lighting’s LED numbers compare to the existing types of lighting (CFL, incandescent, etc.).

Again, while cost is one obvious stumbling block in the residential market, it is not the only one. Premature failure is another hurdle for early adopters, and designers have to figure out what to do to prevent product breakdown. The LED lighting solution is a system and there are many contributing factors that must be mitigated to ensure a long-lived fixture design. LED manufacturers must continue to make in-roads into improved reliability with regard to thermal management, manufacturing variances (reduced binning tolerances), overall LED package robustness, and lumen maintenance. Inherently, cost and performance are intertwined through engineering design trade-offs at the product level. Therefore, any improvements on performance (flux, efficacy and color quality) have to be leveraged against system costs in order to address the customers' needs. Other possible methods for lowering costs and customer price point to a combination of manufacturing efficiency and performance improvement via the use of larger wafers, improvements in LED epitaxy, cost of ownership through yield and throughput, improved packaging technologies (phosphors, optics), and improved package and luminaire design.

Power challenges

The lighting power supply also needs to be addressed. Typically, the LED lighting system today uses a two-stage power supply that combines a first-stage boost converter for power factor with a second-stage high voltage DC/DC converter. The weak link in the supply is the electrolytic capacitor that is used for bulk storage between the two stages. These bulk electrolytic capacitors must endure harsh thermal conditions because they operate continuously at full load and typically are placed in tightly enclosed spaces such as a ballast brick or bulb base with heat-generating power supplies and high brightness LEDs. As you may have already guessed, the dielectric material of the capacitor degrades, and the device loses capacitance and fails. While the controllers and other semiconductors used in LED lighting solutions last more than 100,000 hours and diodes, transistors and ceramic capacitors last almost as long, the electrolytic capacitors embedded in most two-stage power supplies is the linchpin of the system as they exhibit an operational life of only about 20,000 hours.

One way to address this problem is to build LED lighting solutions with power supplies that use a topology designed to eliminate both vulnerable electrolytic capacitors and unreliable opto-isolators used in isolated flyback designs. A new generation of single-stage power LED drivers addresses this need by eliminating these potential points of failure. By replacing electrolytic capacitors with highly stable ceramic capacitors, these power supplies can more closely match the longer lifecycles of LEDs. In addition, by operating at efficiency levels in excess of 90 percent, while exceeding Energy Star requirements for PF and THD, these highly integrated converters generate less heat and, in the process, help simplify thermal management issues in highly compact lighting designs. Typically, HB LED lamps typically last 45,000 hours, but the power supplies usually only last about 20,000 hours, so as a result the LED system lifetime is the shorter of the two components.¹

The thermal management challenge for LEDs occurs because LEDs dissipate excess heat into their heatsinks. The heat can be excessive because of the small size of the LED base compounded by potentially high ambient temperatures, which can shorten the LED’s operating life. Thermal management continues to be a challenge, especially in high light-output applications. However, considering that the LED manufacturers have been able to reduce the thermal resistivity of the packages by over two orders of magnitude in the last two decades, they have positioned themselves well for a big push in the general lighting arena. Of course it must be noted that performance and reliability of an LED fixture is not the sole responsibility of the LED manufacturers.²

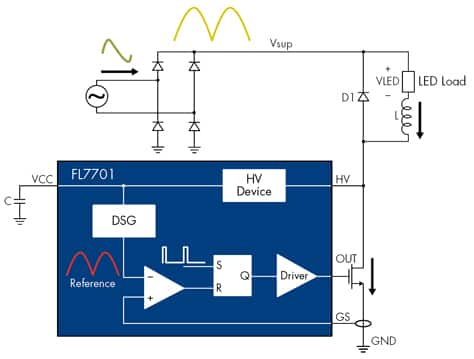

All short-lived electrolytic capacitors can be eliminated with an LED load that does not have tight current ripple specifications, improving the warranty period of the driver. An example is shown in Figure 2 – the Fairchild Semiconductor FL7701. This Smart Buck PFC controller is a much simpler solution when compared to the popular flyback topology which requires a transformer and snubber, and may also require a passive PFC circuit. The Smart Buck PFC avoids having to use a two-stage approach, usually a PFC first stage followed by a second DC/DC stage (which at times is the buck topology).

Consider, also, the Power Integrations LNK403EG LinkSwitch-PH, which simplifies implementation of LED drivers requiring long lifetime, high efficiency, PF > 0.9, and TRIAC dimming capability. The single-stage combined power factor and constant-current controller eliminates a switching stage and the electrolytic bulk capacitor. The part also eliminates the need for an optocoupler and all secondary current control circuitry, as well as control loop compensation circuitry.

Needed: A different approach

Even if these design problems are successfully addressed, the main reason consumers are not jumping at the chance to change to LEDs still remains – price. Residential sockets make up approximately 63 percent of the world’s total, so there is a good reason for LED lamp manufacturers to find a way to decrease the price of their products (see the IMS Research study² “Succeeding in the Global Retail LED Lamp Market; March 2012). The speed at which the lamp price decreases is also very important, since the longer life of LED lamps means that as more are installed in existing sockets the market for replacement lamps will shrink, as replacements will not be required for several years.

Another means of addressing the residential market is to utilize the unique characteristics and strengths of solid-state lighting to help guide the design instead of using it just as a replacement for the incandescent socket. Some companies are doing just that and changing the industry's focus toward integral luminaires rather than replacement lamps. This approach makes it easier to take full advantage of LED lighting's capabilities and strengths. Some think that this approach will enable LED lighting products to better compete with fluorescent and incandescent products on price and performance.

In the same vein, LED modules provide lighting designers and manufacturers with simple, easy-to-adopt LED lighting solutions that reduce luminaire development time and speed time to market. Adoption of LED lighting modules is likely to accelerate as a result of standardization efforts driven by Zhaga, an industry-wide cooperation between companies aimed at enabling the interchangeability of LED light sources made by different manufacturers. The consortium now has over 190 member companies from Europe, Asia, and North America. Interchangeability is achieved by defining interfaces for a variety of application-specific light engines (an LED light engine is defined as a combination of an LED module and the associated control gear). Zhaga specifications cover the physical dimensions, as well as the photometric, electrical, and thermal behavior of LED light engines. Zhaga treats LED light engines as a black box, with defined interfaces that do not depend on the type of LED technology used inside of the light engine. The Zhaga specifications only define the outside of LED light engines.

In summary, although LED lighting for residential applications is significantly better than what is available now, there are some problems with early failure that can be solved, and the biggest issue of price must be addressed if the manufacturers are to be successful in the residential market. From a technology standpoint, there are challenges in thermal management to be addressed when retrofitting LED-based bulbs to fit a socket designed for an incandescent bulb. The higher temperatures of these fixtures may damage the LED or even cause permanent failure. Incandescent bulb retrofits also must address such aspects as packaging, line transient immunity, high PF, low line-frequency modulation of LED current and interfacing with legacy dimmer switches. Good progress is being made on all of these fronts and, as shown in Figure 1 above, tremendous growth is anticipated in LED revenue from general lighting applications going forward.

References:

- Power Integration, “Redefining the basic assumptions of lighting”, Doug Bailey, A161.

- IMS Research, Succeeding in the Global Retail LED Lamp Market March 5, 2012

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国