LEDs for Everything - New Directions in Lighting

投稿人:Convergence Promotions LLC

2011-12-06

The drive for power efficiency has now moved to include lighting as a major growth area. LEDs as the core of solid state lighting (SSL) is the key to this new market and are applicable to most products. The LED marketplace includes the traditional indicator devices which have been a mainstay of the automotive dashboard indicators and secondary lighting applications for many years. The advent of the "white" LEDs has now brought the devices to the general lighting and the display backlighting market. The SSL ecosystem includes connectors, specialized wiring, drivers, power regulators, wireless connectivity, and thermal management products, in addition to the LEDs themselves. A discussion of the applications of SSL in the commercial, industrial and automotive marketplace follows.

Lighted indicator solutions

The typical image that comes to mind when people mention LEDs is the lighting up of the red power indicator light near a switch. If you ask further, this may include the exotic derivations of yellow or green single LEDs also in an indicator function. The reality is that using LEDs as a lighting source for display applications is becoming mainstream. Additionally, almost any application that uses incandescent or fluorescent lighting (including CCFL) can be updated to use LED lighting. The advantages of LEDs are many. They are lower power, generate less heat, are available in a number of form factors, have a very long operating life, and are insensitive to movement and vibration. A further ecological advantage is that the lighting control circuits do not contain any hazardous materials such as mercury, and can be made lead free.

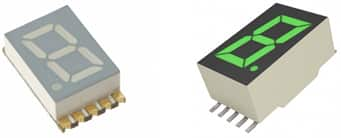

To support LEDs, DigiKey has two distinct paths: those for standard, daylight readable and IR indicator LEDs, and those for lighting applications. The first group is organized under the topic of optoelectronics. This category includes dot matrix displays, character displays, and individual/grouped LEDs. These are designed for use in regulated power supply systems for function indication and status. They are available in a variety of shapes and mounting styles, as shown in Figures 1 and 2.

Figure 1: Seven segment character display LEDs.

Figure 2: Dot matrix LED display.

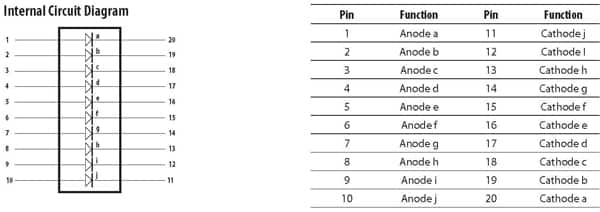

The individual LED elements are sometimes grouped into modules. The modules are available in two forms: multiple LEDs only and the LEDs with other electronics. The additional electronics include pull-up or pull-down resistors, driver logic, and decode logic. Most of the multi-segment display modules have direct access to the LEDs in either a common cathode or common anode configuration. For bar style indicator displays, the LEDs are wired straight through on a two-pin per LED configuration. The schematic is shown in Figure 3.

Figure 3: Schematic for indicator bar LED module.

Higher end modules, such as the OSRAM PD243X, PD353X, and PD443X feature both multi-character displays and an arrangement of the LEDs as a dot matrix display. These displays are designed for integration with standard CMOS logic and CPUs. They feature built-in memory, decoders, multiplexers, and drivers. The device also includes software control (SDKs) for the device that supports blinking, memory clear, lamp test, display blank, single/multiple character blink, and multiple brightness levels. The use of the indicator modules simplifies the system design, as all of the timing needed for these functions is included in the part, and the application board results in a single device footprint for the display.

The individual LED elements, due to their mounting and connection requirements, may not be immediately visible in the final enclosure. In order to address this issue, DigiKey carries a full line of optics. There are available from some of the same suppliers as the LEDs, including Avago Technologies, Inc., Chicago Miniature Lighting LLC, Dialight, Lumex Inc., Molex, Panasonic and TE Connectivity. The optics includes reflectors, side emitters, lenses, lamp holders, remote phosphors and light pipes. The standard optics redirect the LED light locally to extend to the outer shell of the product design. The optics also provide alternate mounting solutions for the displays.

The lighting products are graded as low, medium, and high brightness. The LEDs are also available at specific color frequencies based on the target application. As a result, there is no such thing as a "red" LED. Rather, there are specific wavelengths of red which are output from the LED, and the lensing allows this frequency to be magnified. The brightness levels have a lot to do with the use model – indoors, outdoors, automotive, systems control, daylight readable, etc. The power associated with the devices also scales with brightness, so choosing the right one does matter. In addition to the power, the visual look is affected by the brightness, the frequency, and the optics. The designer has to understand the use and application. For example, the light for your air conditioner button in your car should be small, bright, and blue so you can see it during the day, in contrast, you would not use a large, high brightness green LED for an alarm keypad, as it will effectively light the room and provide a great deal of glare to the operator of the keypad.

Lighting and HB LED solutions

In moving away from the indicators, which have been the staple of the LED industry since the 1970s, we moved to solid state lighting. This marketplace is dominated by both high brightness (HB) LEDs and white LEDs. Alberto Barbieri at the Cardiff University Laboratory investigated the efficiency and reliability of high brightness LEDs and demonstrated a very impressive result by using a transparent contact made of indium tin oxide (ITO) on an (AlGaInP/GaAs) LED. The existence of blue LEDs and high efficiency LEDs quickly led to the development of the first white LED, which employed a Y3Al5O12:Ce, or "YAG", phosphor coating to mix yellow (down-converted) light with blue to produce light that appears white. This was quickly commercialized by companies such as Cree. Cree's XLamp™ XM-L white LEDs became available this year, and can produce 100 lumens per watt at its full power of ten watts, and up to 160 lumens per watt at two watts of input power.

These high brightness and white LEDs have made their way into mainstream lighting applications, transportation lighting, and general low-power lighting. The advantage in power stems from the light generation technologies. Incandescent lights output 15 lumens per watt for a typical 60 to 100 watt application. A fluorescent light outputs approximately 100 lumens per watt in a 35 to 40 watt power level. LEDs operate in the milliampere range, providing 65 lumens for a 20 mA power draw. Since the devices are used in general lighting, the power moves up to about 350 mA.

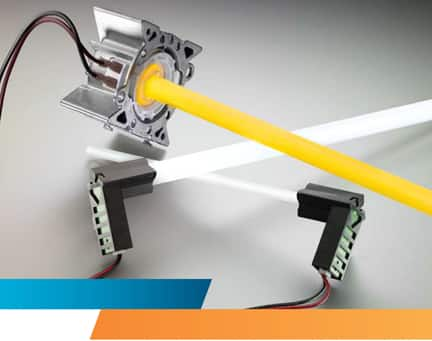

Automotive lighting has been one of the early adopters of LED lighting. The long life cycle, solid state construction, which is unaffected by vibration, low power, and light weight make them a natural fit. For these applications, the LEDs are located in one spot, and the light is routed around using a light pipe to fit the contours. DigiKey supplies light pipes under their lighting solutions sections. The light pipes are generally used with LEDs of all colors to provide accent/trim lighting found in commercial building, industrial, appliance, rail, motor vehicle, and commercial aircraft applications. They are a linear light source, such as those using TE Connectivity’s proprietary large core optical fiber rod that projects a band of light along the entire length of the light pipe using one or more LEDs. The TE Connectivity Light Pipe is shown in Figure 4.

Figure 4: TE connectivity Light Pipe (Courtesy TE Connectivity).

Light pipes and reflectors are the basis for new low-power backlighting for LCD and displays. DigiKey light pipe kits allow for creating new industrial design by having standard parts channel the light horizontally, vertically and along flexible paths. These kits are available from Dialight and Lumex Inc., among others. Most of the optic components are “snap-in” so they are compatible with post assembly over surface mount LED, that are ROHS and wave solder compliant.

For general lighting, there is more than just the light output and the placement of the light with respect to the industrial design. General use lighting has thermal management and power drive (i.e., dimming and control) aspects. Cree Inc., Cypress Semiconductor, Infineon Technologies, Linear Technology, Lumex Inc., National Semiconductor, and NXP Semiconductors all have product training manuals which provide an overview of their development kits. A typical evaluation kit, such as the Cree LED Module LMR4 evaluation kit, is shown in Figure 5. The development kit includes light modules based on the Cree LEDs, two heat sinks for the lights to stay operational, a dimmer switch with control logic, manuals, and all the plugs and wiring needed to connect the module to standard AC voltage. Other kits from other manufacturers include similar pieces, where some are based on low voltage supply operation versus standard line voltage.

Figure 5: Cree LED Module LMR4 evaluation kit (Courtesy CREE, Inc.).

The kits allow for the creation of the product design around the lighting module and the manufacturer takes care of all of the electronics. The product design task is then limited to the optics design and the creative industrial design. Examples are shown in Figure 6. To help with the design implementation, there are many application notes direct from the manufacturers. These address the real world issues such as thermal response and degradation characteristics, issues for handling wave solder, determining the efficiency of the DC and AC performance of the LEDs, dimming control, and power control for the LEDs.

Figure 6: Cree lighting design examples for LMR4 (Courtesy CREE, Inc.).

Designing with LEDs affords engineers the advantage of being able to choose the light color. For example, the Cree CXA2011 lighting kits feature warm white light in the color temperature range of 2700K to 5000K. Several other series have whiter and cooler colors. These specific lights do not drift over time, and their focus and view/projection angle can be tailored with the optics. Another system available from DigiKey services the interior lighting for buildings. TE Connectivity’s NEVALO™ lighting series includes a training video and whitepapers and provides a full development environment of power supplies, wiring, lighting sockets, LED boards, optics, and thermal heat sinks. These components are supported by drill templates, web-based configuration tools, SSL budgeting system and a thermal test instruments with test boards. All of the support tools and the SSL product system are available as part of the DigiKey lighting solutions TechZone.

Due to the power and labor savings, reduced replacement cost, and reduced manpower for the maintenance of the lighting, the interior lighting market is driving the use of turnkey development systems and high automation compatible lighting solutions. Most of the individual LEDs are available in high speed tape and reel, cut tape and Digi-Reel® form to simplify high volume surface mount assembly.

Summary

Solid state lighting is a rapidly growing area, primarily differentiated by industrial design and component mix at the system level. The new features for these products can be designed with full component development kits and software available as kit form. The products consist of LED elements, power and thermal management controls, and the optics design. These optic products are available in various grades from commercial products from industrial through aircraft/automotive.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国