ICs Simplify Backup Power in Energy Harvesting Designs

投稿人:电子产品

2015-03-11

Periodic peaks in power demand or occasional fluctuations in ambient energy sources can leave energy-harvesting circuits starved of power without warning. Single-cell lithium-ion batteries can offer a convenient reservoir of power but demand careful control over charge and discharge cycles. To implement backup power in energy-harvesting designs, engineers can find ready solutions through a variety of power management ICs (PMIC) and energy-harvesting devices from vendors including Analog Devices, Linear Technology, Maxim Integrated, and Texas Instruments, among others.

Single-cell lithium-ion batteries can smooth power fluctuations by providing sufficient energy storage needed to survive occasional loss of ambient-energy sources or periodic increase in power demand. At the same time, improper management of these cells can lead to internal imbalances that will eventually degrade energy-storage capacity or even irreversibly damage the cell itself.

Charge/discharge cycle

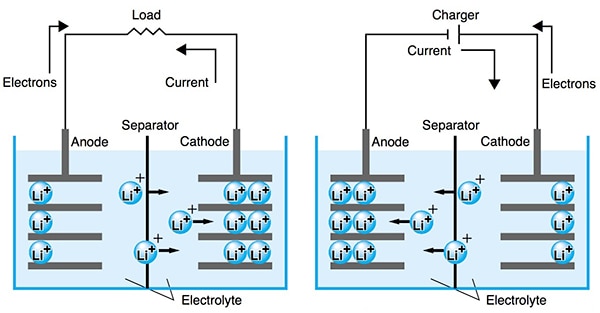

Rechargeable lithium-ion cells rely on the migration of Li-ions between the anode and cathode during discharge and charge cycles (Figure 1). If a cell is discharged below its recommended minimum voltage, lithium can plate out on the cathode and even lead to an internal short circuit. If a cell becomes overcharged, lithium can similarly precipitate on the anode and create an internal short circuit if overcharging continues.

Figure 1: If Li-ion cell discharge (left) falls below the minimum voltage, lithium can collect on the cathode and create an internal short circuit; if the cell charge (right) exceeds the maximum voltage, lithium collection on the anode can similarly lead to a short circuit. (Courtesy of Sony)

To help ensure proper operation, maximum capacity and extended-lifetime, battery manufacturers provide strict specifications on procedures for safe charging and discharging their products. The maximum rates for charge and discharge currents are defined relative to battery capacity, expressed in C units. So, for example, a battery subjected to its 1 C discharge rate will nominally go from full charge to empty in one hour.

The process for charging Li-ion cells follows a characteristic profile, first using a constant current of 1 C to bring a cell to its target voltage and then applying a constant voltage source until the cell reaches its maximum-charge state. The switch between constant-current and constant-voltage modes must typically be held within tight tolerances. For severely depleted cells, this characteristic charging profile is often preceded with use of a lower current such as 0.1 C to bring the cell to normal minimums.

While commercial multi-cell Li-ion battery packs are sold with integrated protection circuits, single-cell Li-ion batteries such as the FDK ML621, Seiko Instruments MS412FE, or Panasonic ML1220 require designers to build in appropriate protection mechanisms. With the availability of dedicated Li-ion charge management ICs and suitable energy-harvesting ICs, engineers have access to a wide range of devices able to address Li-ion cell requirements.

Li-ion management ICs

Li-ion cell management ICs are designed to monitor the voltage of a cell and terminate the charge if cell voltage rises above a preset value. During discharge, these devices are designed to isolate the cell from the load when cell voltage falls below a preset value.

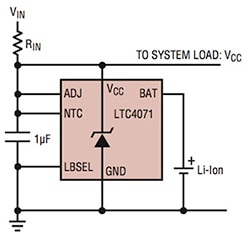

Designed to provide an integrated solution to Li-ion cell management, devices such as the Linear Technology LTC4071 and Texas Instruments BQ24210 can often be dropped easily into designs, requiring few additional components to support Li-ion cell requirements. For example, the Linear Technology LTC4071 needs only one external resistor to provide a complete Li-ion cell-charging solution (Figure 2).

Figure 2: Li-ion management ICs such as the Linear Technology LTC4071 battery charger IC provide a simple solution for protecting a Li-ion cell from overcharge and overdischarge. (Courtesy of Linear Technology)

Linear designed the LTC4071 to charge Li-ion cells from the kind of low-current or intermittent-charging sources often associated with ambient energy harvesting. The device provides a low-battery disconnect function that consumes less than 0.1 nA, while protecting the Li-ion cell from potentially damaging overdischarge. Similarly, the TI BQ24210 requires only a few external resistors while providing an extensive set of battery-management functions including battery detection, pre-charge for heavily depleted batteries, fast charge, charge termination, battery-temperature monitoring, and more.

Combined functionality

In addition to dedicated Li-ion cell management devices such as the Linear LTC4071 and TI BQ24210, engineers can find specialized ICs that combine energy-harvesting functionality with Li-ion cell management capabilities. For example, the Maxim Integrated MAX17710 is designed to harvest energy from a variety of low-power sources while maintaining required cell charge and discharge voltages. An on-chip boost converter can charge a Li-ion cell from sources as low as 750 mV, while a separate output regulator includes internal voltage-protection features that prevent the cell from overdischarging.

The Texas Instrument BQ25570 also uses an integrated booster to charge an external Li-ion cell while harvesting energy from microwatt-level ambient sources. Its on-chip maximum power-point-tracking (MPPT) controller helps optimize power output from energy sources, while its battery-management features prevent overcharge and overdischarge of a Li-ion cell. During operation, the device disconnects the cell from the load when cell output falls below a preset undervoltage threshold of 1.95 V. If the cell-charging voltage reaches an overvoltage threshold programmed with external resistors, the device disables the on-chip boost charger. Furthermore, the device provides a programmable “power good” signal that operates independent of the undervoltage and overvoltage threshold features to signal the application when the device’s output voltage operates within acceptable levels.

Devices such as the Linear Technology LTC3331 and Analog Devices ADP5090 combine energy-harvesting capabilities with features specifically designed to support power-backup requirements. For example, the Linear LTC3331 integrates a complete energy-harvesting power supply with a separate power path that enables operation from a backup Li-ion cell when energy from ambient sources falls below required levels. During operation, when sufficient harvested energy is available, the device disables a buck-boost regulator powered by the cell, reducing cell power consumption to 220 nA. In addition, the device uses excess harvested energy to recharge the Li-ion cell with its integrated-current shunt-battery charger. When harvested energy falls below minimums, the device switches its output to the cell-driven buck-boost regulator to allow continued operation of the load from the Li-ion cell. The LTC3331 includes a low-battery disconnect feature designed to prevent overdischarge by disconnecting the cell at a programmable threshold voltage.

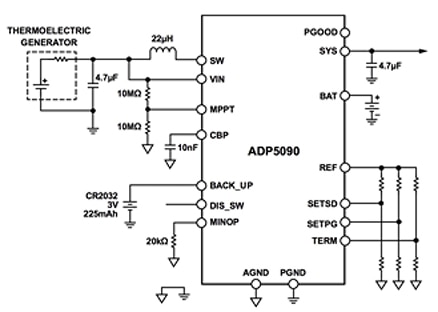

The Analog Devices ADP5090 is an energy-harvesting IC that integrates a boost regulator, on-chip MPPT capabilities, and backup-power management. In fact, along with power from harvested-energy sources, the ADP5090 can provide power to the load from backup power using a primary battery such as the familiar CR2032 or using a rechargeable cell such as those mentioned above (Figure 3).

Figure 3: While several energy-harvesting ICs include Li-ion cell management, the Analog Devices ADP5090 provides an additional option for power backup with support for both a rechargeable cell (BAT pin) and a primary battery (BACK_UP pin) such as the CR2032. (Courtesy of Analog Devices)

The ADP5090’s integrated-power path-management controller automatically switches the power source from energy harvester, primary battery, or rechargeable cell as needed. When sufficient harvested energy is available, the ADP5090 uses that to power the load and recharge the secondary cell. While charging the secondary cell with its boost regulator, the ADP5090 monitors cell voltage and when the voltage reaches the programmable-charging-termination voltage, the device terminates charging by disabling the boost regulator. If harvested energy falls below required levels, the device disables the boost converter and connects the secondary cell to the load. If cell voltage drops below the programmable-discharging-protection threshold level, the device disconnects the cell. If both cell voltage and harvested-energy output fall below required levels, the ADP5090 can power the load from the backup primary battery.

Conclusion

Li-ion cells offer a convenient solution for meeting peak power demand or ensuring operation during fluctuations in ambient-energy sources. Still, these cells require careful control of cell voltage and current to avoid irreparable damage. To cope with these challenges, engineers can take advantage of ICs designed with dedicated Li-ion cell management capabilities or specialized ICs that integrate these capabilities with their energy-harvesting functionality. Using these devices, engineers can augment their designs with Li-ion cell backup power with a minimum of additional components.

For more information about the parts discussed in this article, use the links provided to access product pages on the DigiKey website.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国