How to Enable the Building Internet of Things

投稿人:DigiKey 欧洲编辑

2015-10-22

Wireless technologies are particularly suited to the automation of buildings, adding intelligence quickly and easily without the need for complex and expensive wiring. This has implications for the power budget available to the designer through the choice of technologies and allows the designer to maximize the battery life of wireless nodes and minimize the cost of automating large buildings.

Adding automation to a building can cut running costs by up to 30% by optimizing the heating and air conditioning to minimize the power use. This requires a network of wireless sensors linked together, usually with a hub controlling the network. In the past, this hub has been a proprietary controller for the building, but now with the Internet of Things (IoT), this hub is a gateway to bigger things. This is opening up the Building Internet of Things (BIoT) where the wireless nodes feed data into the cloud for advanced analytics and greater control.

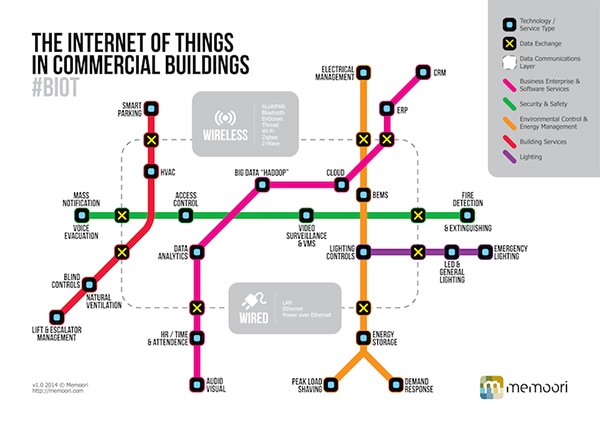

Market research company Memoori sees the BIoT as an overlay of an IP network on the sensors, connecting all the building services while monitoring, analyzing and controlling without the intervention of humans. Collecting data from the services and equipment around the building provides a much more granular view of exactly how each building is performing, allowing operators to collect, store and analyze data in the cloud so that they can use it to provide better operational efficiency. Memoori estimates the overall market for systems in buildings growing from $110.9 Billion in 2014 to $181.1 Billion in 2020, with the three largest market segments being physical security, lighting control and fire detection. Within this, the company sees the global market for the Internet-enabled devices within the building rising from $22.93 Billion in 2014 to over $85 Billion in 2020.

Figure 1: There are many different ways to implement the Building Internet of Things, and wireless connectivity is an essential capability. Source: Memoori.

Much of this growth comes from the fact that connectivity within building systems is only 16% today and will grow to 50% by 2025. This growth depends on the implementation of the technology available to the designers, and there are a range of low- and high-level standards emerging. For example, B-control is a new high-level standard from the B-control Alliance. This is driven by two German companies, TQ-Group and nxtControl, alongside Vestamatic and U::Lux. This alliance is a co-operation between manufacturers to provide their components in the building technology by synchronizing their units in a "pre-integrated" form of application.

Another group, the EnOcean Alliance, has 350 companies using the 315 MHz unlicensed band as well as the 868 MHz unlicensed band in Europe and 902 MHz in the US with a focus on powering the wireless nodes using energy from the environment such as solar cells, thermal heat engines or kinetic energy sources from switches. This uses a protocol developed by EnOcean and now part of the ISO/IEC 14543-3-10 standard from the International Electrotechnical Commission (IEC). This allows designers to develop equipment that will easily interoperate and can use energy harvesting as the source of power for the wireless nodes. This allows modules such as the STM300 from enOcean to be easily added to a design, but enables developers to use their own implementation as well. Some of the alliance partners are now developing Internet gateways to allow these nodes to efficiently connect to the Building IoT infrastructure.

Figure 2: enOcean’s STM300 wireless transceiver can be powered by solar cells or even from the kinetic energy from the movement of a switch.

However, with the advent of Internet connections there is now a wider range of underlying protocols for building automation. Many of these are based on the IEEE802.15.4 standard, with the ZigBee, 6LoPAN and Thread protocols all using this approach. However, there is also increasing use of Bluetooth and IEEE802.11 Wi-Fi to provide that connectivity.

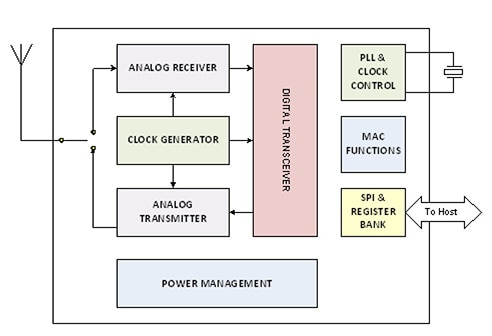

Devices such as the MKW2x from Freescale Semiconductor address a number of monitoring and control applications for the Internet of Things, including building automation. These can operate in the sub-1 GHz and 2.4 GHz unlicensed bands and implement 802.15.4, ZigBee and Thread protocol stacks. The MKW2x is a low power, compact integrated device consisting of a 2.4 GHz IEEE802.15.4-compliant radio transceiver coupled with an ARM Cortex-M4 microcontroller with connectivity and precision mixed signal analog peripherals.

Figure 3: Freescale’s wireless microcontroller development kit allows designers to easily implement multiple nodes for the BIoT.

The devices are used to easily enable connectivity based on the ZigBee Pro network stack and application profiles for Building Automation, as well as the ZigBee IP network stack and the Smart Energy 2.0 application profile that allow the data to be easily transferred between nodes.

The microcontroller allows different protocols to be implemented, with up to 512 KB of Flash memory for program storage and 64 KB of SRAM for code execution. However, it also includes a 16-bit analog-to-digital converter to simplify the design of the node and a Cryptographic Acceleration block to provide security for the data. The radio transceiver of the MKW2x has up to -102 dBm receiver sensitivity, +8 dBm maximum transmit output power, and up to 58 dBm channel rejection, with a transmit current consumption of 17 mA at 0 dBm output power, and peak receive current of 15 mA in Low Power Preamble Search mode.

Size is also important for building controls, as the wireless node has to fit into small form factor items of equipment. The MKW2x is packaged in an 8 x 8 mm LGA with sixty-three total contacts, and operates between 1.8 V and 3.6 V.

These are not the only bands to use for a building automation system. Decawave, for example, has used six frequency bands from 3.6 GHz to 6.5 GHz for its ultra-wideband DW1000 ScenSor (Seek Control Execute Network Sense Obey Respond) single-chip transceiver that is also able to run the 802.15.4 protocol. This allows high data rates up to 6.8 Mb/s and a range of up to 300 m as a result of the coherent receiver techniques in the transceiver. The ultra-wideband approach is also immune to multipath fading, which can be a problem in building environments where there are lots of reflections. The low-power design with a transmit power of -14 dBm and transmit current of 31 mA allows for a long battery life and a small 6 x 6 mm package size to fit into the wireless nodes.

Figure 4: Decawave’s DW1000 ultra-wideband transceiver uses frequency bands from 3.5 GHz to 6.5 GHz for low-power links that are resistant to multipath fading from reflections in buildings.

Using a module can be an efficient way to add wireless capability to a sensor or control node for a building automation system. Atmel’s ATZB-S1-256-3-0-C ZigBit module combines the wireless transceiver with an 8-bit microcontroller to handle sensor data from 250 kb/s up to 2 Mb/s, as well as the frame handling, receiver sensitivity and high transmit output power for a robust, self-healing mesh network. By combining the chip antenna with the hardware and software for the wireless node, developers can focus on the integration of the sensors with the rest of the system. Using the 802.4.15 mesh networking protocol allows additional nodes to be easily added to the network, as the nodes communicate through the nearest neighbor. This provides a scalable and robust topology for building automation designs. The data can then be fed back to a gateway that is connected to the Internet for control and analysis.

Figure 5: Atmel’s ZigBit module integrates the chip antenna, wireless transceiver system-on-chip and 8-bit microcontroller to simplify the development of a wireless node for the BIoT.

The compact module measures 30.0 × 20.0 mm and has a receive sensitivity of -97 dBm and a link budget of up to 100.6 dB from an output power of +3.6 dBm. This can be used to extend the range of the link so that fewer nodes are used, or reduce the power of each node by having them closer. This can take some complex network topology analysis to get the right balance of nodes through the building, but with BIoT the data from the nodes can be analyzed to determine the optimum location of each node. Then, over time as new nodes are added, the network can be refined to provide the right balance of data from sensors and control units all linked wirelessly.

A key advantage for the designer with the module is that there are up to thirty-one configurable lines of general purpose IO so that sensor data can be brought in and control data delivered to an actuator such as a door lock or window opener. To further simplify the design of the node, each module has a preassigned MAC address that can be used on the end product, and this can be stored in the internal EEPROM. This can dramatically simplify the configuration of the end equipment by the building operator.

Conclusion

Adding the capabilities of the wider Internet to building automation equipment is a tremendous opportunity for developers to deliver significant cost savings to building operators. Providing wireless nodes that are linked to sensors and actuators, coupled with data analyzed on the Internet and the ability to control these nodes from any device, gives a dramatic boost in the functionality of such systems. This can be delivered from the 315 MHz bands all the way up to 6.5 GHz, with different engineering and design tradeoffs for the different solutions. However, all need to be powered by the lowest possible current to maintain the longest possible battery life.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。