SME 如何利用工业虚拟实境快速探索和部署机器人解决方案

投稿人:DigiKey 北美编辑

2024-11-21

机器人和协作机器人 (cobots) 处于工厂自动化技术的前沿。数字双胞胎和虚拟现实 (VR) 技术则处于设计和开发工具的前沿。将两者结合,可以构建一个工业虚拟实境,从而更快地提高生产率,即使是中小型企业 (SME) 也能实现这一目标。

SME 的设计人员可以从简单直观的界面中获益,该界面结合了数字双胞胎、Delta 机器人、线性机器人或多轴机器人等实体设备的高精细虚拟模型以及 3 维 (3D) VR 环境,可以直接执行和检查机器人的运动序列。

利用这些功能,即使没有任何物理硬件,也能对自动化系统进行微调和优化,并快速探索多种解决方案的可能性。

本文首先回顾数学数据描述型数字双胞胎与可视化数字双胞胎(VR 孪生)之间的区别,以及创建工业虚拟实境时为何需要这两种技术。然后,介绍 Igus 机器人控制系统及相关软件。找各种控制系统及软件可用于在 3 维界面(可视数字双胞胎)上模拟机器人,而无需使用任何物理硬件。此外,还介绍用于实现优化解决方案的兼容型 Delta、线性和多轴机器人。

数字双胞胎和 VR 现实是互补技术,使用不同的可视化形式、交互方式和硬件。数字双胞胎是基于数据的物理对象、系统或流程模型。数字双胞胎适用于建模项目从最初构思到退役和回收的整个生命周期。

VR 是也是一种使用数字模型且基于视觉的沉浸式技术。在 VR 环境中,可以模拟物体之间的关系和互动,就像机器人执行任务一样。因此,虽然这两种技术都可用于设计和模拟,但数字双胞胎技术侧重于整体生命周期的考虑,而 VR 则侧重于物理对象之间的交互。

虚拟实境 (metaverse) 将数字双胞胎和 VR 结合到一个专门创建的虚拟环境中,支持数字对象和人之间的实时互动。虚拟实境通常与游戏有关,但也越来越多地应用于商业和工业活动中。

欢迎来到 iguverse

Igus 开发出 iguverse 虚拟实境,以支持工业环境中的工程互动,如开发和部署机器人系统。iguverse 可通过 Igus 机器人控制 (iRC) 软件实现。使用这款免费且无需许可证的应用,用户可以控制各类机器人,包括 Delta 机器人、协作机器人(机器人手臂)和龙门机器人。

该应用为用户提供了 3D 界面和 100 多个样例程序。实施 iRC 的系统要求包括一台安装了 Windows 10 或 11(64 位)操作系统,具有 500 MB 可用磁盘空间和以太网或无线网络连接功能的个人电脑(最低配置为 Intel i5 CPU)。

该软件的核心是正在进行编程的机器人 3D 数字双胞胎。例如,工作空间为 500 x 500 x 100 mm 的三轴线性龙门机器人(如 DLE-RG-0001-AC-500-500-100 型机器人)或工作空间为 800 x 500 mm 的双轴 xy 执行器(如 DLE-LG-0012-AC-800-500 执行器)(图 1)。设计人员只需点击几下鼠即可能定义动作,甚至在购买机器人之前就能使用 3 维模型确保所需的动作是可行的。

图 1:iguverse 中三轴龙门机器人的 3D VR 数字双胞胎示例。(图片来源:Igus)

图 1:iguverse 中三轴龙门机器人的 3D VR 数字双胞胎示例。(图片来源:Igus)

除 iRC 软件外,机器人控制器也是 iguverse 开发环境的关键要素。例如,IRC-LG12-02000 型控制器适用于 48 V 电机,有七个输入端和七个输出端,并配有一根 10 米长的电缆用于连接机器人。IRC 控制器包括电机驱动模块,适用于各种尺寸的双极步进电机,且可进行配置或预配置。这种控制器还配备了多个用于系统集成的接口或界面,具体如下:

- 可编程逻辑控制器 (PLC) 接口,用于通过数字输入和输出进行控制,特别是通过 PLC 或按钮轻松启动和停止程序

- Modbus TCP 接口,可通过 PLC 或 PC 进行控制

- 通用机器人接口 (CRI) 以太网,用于使用 PLC 或 PC 进行控制和配置

- 机器人操作系统 (ROS) 界面,用于使用 ROS 操作机器人

- 物体探测摄像头接口

- 用于远程监控机器人状态的云接口

可支持的运动

由 iguverse 支持的、定义机器人受控动作的各种运动(基本运动)。除了预配置的运动外,还可在 IRC 中配置多达三个在运动方面相互独立的轴。预配置的运动功能包括:

- 2 轴和 3 轴 Detal 机器人

- 龙门机器人

- 2 轴(X 轴和 Y 轴)

- 2 轴(Y 轴和 Z 轴)

- 3 轴(X 轴、Y 轴和 Z 轴)

- 机器人手臂(协作机器人)

- 3 轴(1 轴、2 轴、3 轴)

- 3 轴(2 轴、3 轴、4 轴)

- 4 轴(1 轴、2 轴、3 轴、4 轴)

- 4 轴(2 轴、3 轴、4 轴、5 轴)

- 5 轴(1 轴至 5 轴)

- 6 轴(1 轴至 6 轴)

- 4 轴 SCARA 机器人

编程简单,可实现低成本自动化

Igus 机器人和 IRC 旨在支持低成本自动化。如果没有一个易用的编程界面,就不可能做到这一点。仅需一个 3 键鼠标或游戏手柄就能在 iguverse 中移动和定位机器人。利用 IRC 软件,用户可以在 3 维界面上自由移动数字双胞胎的所有轴。即使没有连接实体机器人,示教功能也能支持机器人控制软件的开发。

要实现示教,用户需要手动将虚拟机器人移动到所需位置,并定义其移动方式。重复这一过程,直到构建出完整的运动曲线。IRC 软件中的工具中心允许用户轻松添加匹配的末端执行器(如抓手),并自动调节机器人上的工具中心点。此外,还可连接到更高级别的工业控制系统。

过程开始时,首先根据需要使用界面上的“连接”、“重置”和“启用”按钮激活机器人。IRC 上的 LED 状态指示灯应变为绿色,此时状态应显示“无故障”。现在可以使用“慢跑”选项卡输入运动曲线(图 2)。

图 2:iguverse 沉浸式开发环境中的 "慢跑 "选项卡(左下角)可用于输入运动曲线。(图片来源:Igus)

图 2:iguverse 沉浸式开发环境中的 "慢跑 "选项卡(左下角)可用于输入运动曲线。(图片来源:Igus)

龙门机器人

就像上述例子中的 iguverse 机器人一样,龙门机器人由两个基本 X 轴、一个 Y 轴和一个可选的 Z 轴组成。Y 轴与两个平行的 X 轴相连,在二维空间中来回移动。可选的 Z 轴支持第三维运动。

Igus 的龙门机器人采用自润滑塑料衬垫,与传统的滚珠轴承设计相比,滑动和滚动更加平稳、安静。新设计重量更轻、耐腐蚀、免维护,这些都是 SME 的重要质量要求。这些机器人的成本比传统龙门机器人低 40%,投资回报 (ROI) 更快,这对中小企业也至关重要。

这些机器人适用于两类应用:低速大负载或高速小负载。代表性的应用包括包装、拾放、贴标签、材料搬运和装配操作。

这些机器人的尺寸大小不一。可用的附件包括联轴器、末端执行器和电机法兰。中型龙门机器人如下:

- DLE-FG-0006-AC-650-650 是二维平板式龙门机器人,工作空间为 650 x 650 mm。该机器人可处理重达 8 kg 的有效载荷,动态速率高达每分钟 20 次拾取操作。

- DLE-RG-0012-AC-800-800-500 是三维龙门架,工作空间为 800 x 800 x 500 mm。这种机器人可以处理重达 10 kg 的有效载荷,动态速率高达每分钟 20 次拾取操作。

码垛能力

将产品码垛以便装运,是制造业和物流业的日常操作。iguverse 的最新最大产品是 XXL 大型龙门机器人,其工作空间为 2,000 x 2,000 x 1,500 mm,非常适合 10 kg 以下的码垛应用。提供最大定制设计工作空间为 6,000 x 6,000 x 1,500 mm 的定制设计。

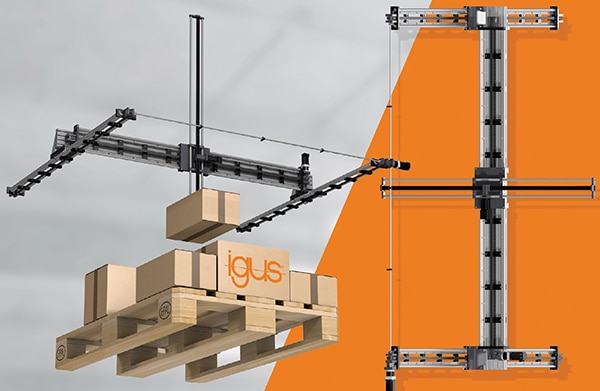

这些龙门机器人可以拾取重达 10 kg 的零件,以每秒 500 mm 的速度传送并将其放置在托盘上,重复精度为 0.8 mm(图 3)。与同类系统相比,Igus 码垛机器人解决方案的成本最多可降低 60%。

图 3:码垛是制造和物流作业中常见而重要操作活动,可使用龙门机器人实现自动化。(图片来源:Igus)

图 3:码垛是制造和物流作业中常见而重要操作活动,可使用龙门机器人实现自动化。(图片来源:Igus)

Delta 机器人

与龙门机器人一样,Delta 机器人也提供两轴或三轴选择。Delta 机器人有一个圆顶形的工作包络面,安装在工作区上方。这类机器人具有极快的速度,通常用于物料搬运和零件放置。Igus Delta 机器人如下:

- RBTX-IGUS-0047 采用三轴设计,工作空间直径为 660 mm。这款机器人的精度为 ±0.5 mm,最大有效载荷为 5 kg,最大速度为 0.7 m/s,每分钟最多可拾取 30 次。(图 4)。

- RBTX-IGUS-0059 采用 2 轴设计,工作空间直径为 700 mm。该机器人的精度也是 ±0.5 mm。其最大有效载荷为 5 kg,最大速度为 2 m/s,每分钟最多可进行 50 次拾取。

图 4:Igus iRC 旁边的三轴 Delta 机器人(左)。(图片来源:DigiKey)

图 4:Igus iRC 旁边的三轴 Delta 机器人(左)。(图片来源:DigiKey)

关节臂机器人

iguverse 还支持关节臂机器人。协作机器人可以有 2 到 10 个或更多的轴,也称为自由度 (DOF)。这类机器人通常有较大的工作范围,可以与人合作来完成复杂的任务。Igus 的 REBEL-6DOF-02 型机器人有 6 个 DOF,REBEL-4DOF-02 型机器人有 4 个 DOF。两者的精度均为 ±1 mm,标称工作范围为 400 mm,以 200 mm/s 的线速度,每分钟至少可完成 7 次拾取。

6 DOF 型号的最大有效载荷为 2 kg,最大行程为 664 mm。4 DOF 型号的最大有效载荷为 3 kg,最大行程为 495 mm(图 5)。

图 5:具有 4 DOF(左)和 6 DOF(右)的关节臂机器人。(图片来源:Igus)

图 5:具有 4 DOF(左)和 6 DOF(右)的关节臂机器人。(图片来源:Igus)

总结

iguverse 沉浸式工业虚拟实境结合了数字双胞胎和虚拟现实技术,提供了可快速开发和部署机器人解决方案的工具。这种工业虚拟实境免费,无需许可证,且可在本地 PC 上运行,而无需云连接。这种虚拟实境可用于开发、测试机器人解决方案,而无需实体机器人。

这种虚拟实境支持 Delta 机器人、龙门机器人、协作机器人 (cobots) 和 SCARA 机器人的各种运动功能。IRC 包括一系列支持自动化和操作需求的接口,其中包括 PLC 接口、Modbus TCP/IP、CRI 以太网、ROS 接口、对象检测摄像头接口和云接口。Igus 的 iguverse、iRC 和相关机器人经过优化,可满足 SEM 的低成本自动化需求。

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国