Consider Ceramic Caps for LED Lighting Systems

投稿人:电子产品

2012-06-12

Designing an LED lighting system is becoming a more complex task as designs incorporate electronics for LED dimming, color, wireless control, and system “intelligence.” While engineers typically pay more attention to their choice of power devices, drivers and thermal management circuitry, they should not lose sight of the need to select the right capacitor for the job.

Despite their higher temperature stability and smaller size when compared to such capacitor types as film and aluminum electrolytic, too often designers have passed on the use of ceramic capacitors for LED lighting, largely because of their piezoelectric noise, which admittedly has been a cause for concern.

Another reason for this oversight is the conviction that the capacitor industry is a mature market and the only development work among suppliers is aimed at squeezing higher capacitance/voltage (CV) into smaller packages. This is a mistaken belief. In fact, ceramic capacitor manufacturers continue to look at new materials and electrode designs to improve performance in such areas as acoustic noise, ripple current and DC bias —particularly for target markets such as LED lighting.

This article will look at advances in ceramic capacitor technologies that provide reduced noise and DC smoothing in LED lighting circuits. Examples provided will include Murata's GR3 and RDE series and AVX's QM series.

Ceramic capacitor makers agree that noise is one of the biggest issues for LED lighting designs, particularly as LED dimming becomes more popular. Ceramic capacitors operating with a pulse width modulation (PWM) dimmer circuit can cause acoustic noise and light flickering due to piezoelectric effects within the ceramic material. Another potential obstacle is the capacitive DC bias of the ceramic capacitors, which results in a lower capacitance value.

That being said, it does not take a Ph.D. from MIT to conclude that ceramic capacitors exhibiting lower noise and a higher capacitance value under DC bias will prove attractive for LED lighting designs. Ceramic capacitor suppliers know this, too, and they have taken different roads to resolve these issues, either by using new dielectric materials or by designing new internal electrode structures.

As an example, Murata Electronics made the decision to use a new ceramic material (a Class 2 dielectric with temperature characteristics, X7T) that exhibits a lower piezoelectric content (dielectric constant). This allows for an improved DC bias characteristic, higher allowable ripple current, lower temperature rise, and lower acoustic noise compared to its standard multilayer ceramic capacitor (MLCC) product. The maximum capacitance change over the temperature range of –55° to 125°C is 22 to –33 percent.

Murata’s GR3 and RDE (X7T) series address some of the issues that impact the reliability and performance associated with traditional high-dielectric type ceramic capacitors, according to Murata applications engineer Frank Yang. LED bulb lifetime is expected to range from 25,000 to 40,000+, and is directly related to the reliability of its components, he added.

Since LEDs are robust devices, just about any circuit used with them will negatively impact reliability, so the goal is to select circuits that will have the least negative impact.

For the GR3 and RDE, Murata's focus is replacing aluminum electrolytic and film capacitors where possible. Both series are suitable for use on the primary circuit for AC smoothing/noise filtering and on the output for DC smoothing. Yang said it is his understanding that both film caps and electrolytics are used if the designer needs higher capacitance and voltages.

The GR3 series offers C/V values of 1 uF at 250 V, 560 nF at 450 V and 270 nF at 630 V, while the RDE (X7T) offers parts with the following values: 2.2 µF at 250 V, 1.2-µF at 450 V, and 560 nF at 630 V. In addition, these capacitors are said to offer comparable electromagnetic interference (EMI) suppression with standard film capacitors, while offering a smaller size.

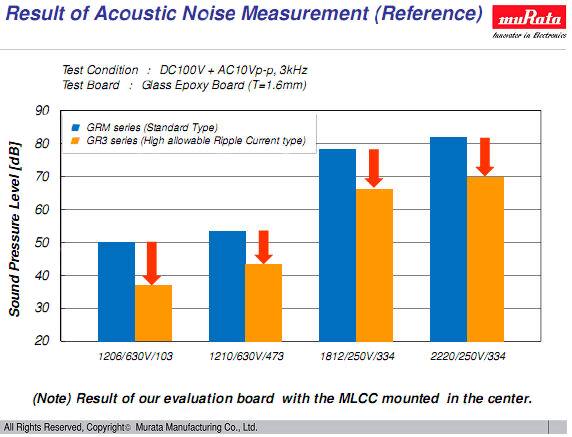

Compared to standard ceramic capacitors (Figure 1), tests show a 10 dB reduction in acoustic noise by using the GR3 MLCC capacitors. Murata said that further noise reductions are possible with the RDE leaded parts. In addition, Murata noted that both families provide better DC bias and acoustic noise reduction performance than the X7R series.

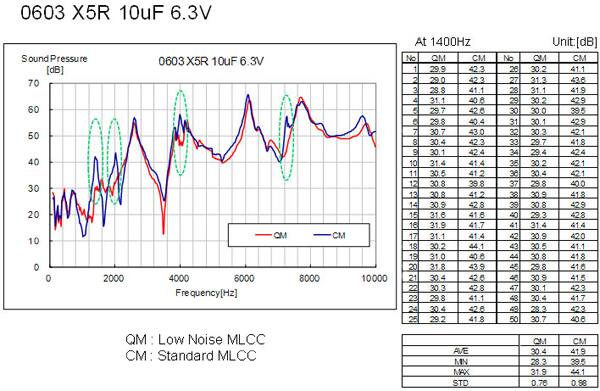

Instead of using a new ceramic material, AVX Corp. developed a new internal electrode structure for its low noise of ceramic capacitors to minimize the output noise. The devices also use a X5R dielectric with a temperature variation of capacitance within ±15 % that allows for higher capacitance and a small package size. The operating temperature range is –55° to 85°C.

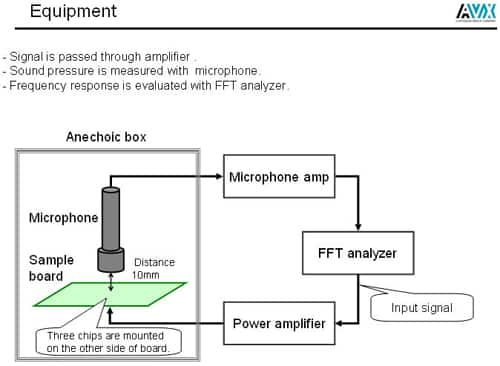

Although AVX cannot reveal too much about the new design, the company noted that standard MLCC construction has a ML electrode direction that is horizontal to the printed-circuit board (PCB), which can allow mechanical resonance from the board and cause noise. The new design "inherently reduces low frequency audio noise," AVX reports (Figures 2 and 3).

These X5R capacitors feature high capacitance in small case sizes (0603 and 0805) with voltage ratings ranging from 4 to 16 V. Capacitance values are typically 10 or 22 µF. In addition to LED lighting, the QM capacitors can be used in a host of other applications including mobile phones, hard disk drives and LCD panel driver circuit applications.

AVX's application engineer Ron Demcko said that compared to other capacitor types, including tantalums, niobium oxide and film, used in output filtering for LED lighting, a big advantage of ceramic capacitors is their small size and low weight. While tantalums or OxiCaps (niobium oxide) would have better noise figures, they are going to be a little bigger and a bit more expensive.

Summary

Designers should always evaluate all capacitor technologies for LED lighting applications, whether they are going to be used in rectification circuitry, output filtering or noise suppression. Performance tradeoffs will be based on each application's requirements.

Looking at ceramic capacitors in particular, designers should not automatically discount them for use in PWM dimming control circuitry because of their piezoelectric noise. Advances continue to be made in capacitor technologies, opening the door to their use in this and other new applications. In the case of Murata's GR3/RDE capacitors and AVX's QM series, the result is lower acoustic noise, along with a host of other performance improvements which allow designers to take advantage of ceramic caps’ small package sizes.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国