Complete AC/DC Modules Simplify Front-End Design for Distributed Power Architecture

投稿人:电子产品

2013-02-26

Distributed power architecture is popular in telecom equipment and data center servers where integrated AC/DC front-end modules are standard subsystems used to power a variety of DC/DC converters spread across system boards. Facing ongoing pressure to deliver more power in a smaller space with higher conversion efficiency (to meet new regulatory standards) and at competitive costs, power supply manufacturers have made significant strides in design, architecture, and packaging. Combining these advances with improvements in semiconductor devices, manufacturers have released a new wave of universal input AC/DC modules with integrated power factor correction (PFC) and input/output filtering.

Capable of handling a universal AC input range of 85 to 264 VAC, these integrated AC/DC converters are complete front-end modules that require no external components. Not only do they provide new levels of power conversion efficiency from light load to full load – even maintaining high efficiency at the low end of the universal AC input – the new modules also meet all noise and EMI requirements imposed by both national and international regulatory agencies.

Complete AC front-end solutions

One such recently introduced complete AC/DC front-end is Vicor’s VI BRICK. It combines architecture, topology, and advanced packaging to realize a complete power-factor corrected (PFC) AC/DC front-end module that raises the bar on power density, conversion efficiency, and flexibility while meeting harmonic noise, EMI, and safety extra low voltage (SELV) output requirements. With a universal AC input range of 85 to 264 VAC, the VI BRICK AC/DC front-end module offers a fully isolated and regulated 48 VDC output from a low-profile package measuring 3.75 x 1.91 in. (95.3 x 48.6 mm), and only 0.38 in. (9.55 mm) in height (Figure 1). As a result, it provides a power conversion density of 121 W/in³ (or 7.5 W/cm³) or 54 W/in³ for a complete supply that includes all necessary components, including hold-up capacitance.

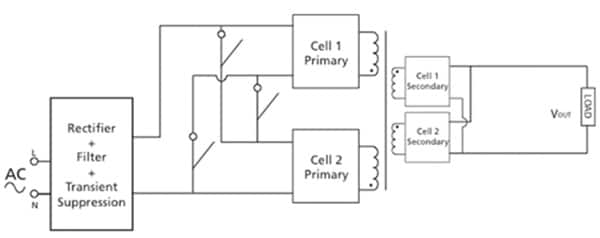

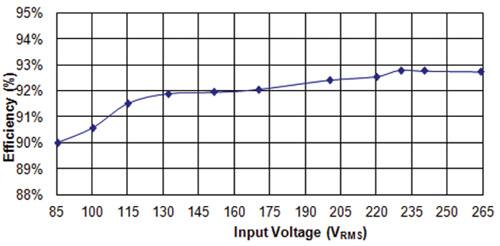

To offer very high power conversion efficiency, the AC front-end module implements Vicor’s proprietary double-clamp zero-voltage switching (DC-ZVS) architecture and patented adaptive-cell topology (Figure 2). Consequently, it delivers peak efficiency of 92 percent with greater than 90 percent efficiency even at 85 VAC input with no derating (Figure 3). Also, by dynamically configuring for AC lines, the adaptive-cell topology allows the AC/DC converter to operate at the same peak efficiency over the universal input range, according to Vicor’s senior product marketing manager, Joe Sullivan. Sullivan notes that because the module has greater than 90 percent efficiency across the entire AC input voltage range, including operation down to 85 VAC, reducing power loss and cooling requirements by 50 percent.

With integrated rectification, filtering, and transient protection, the AC/DC module is a complete front-end system that meets IEC 61000-3-2 harmonic noise and Class B EMI conducted emission limits, while supplying 330 W to external output storage capacitance. The EMC directive EN61000-3-2 was introduced to limit the reflected harmonics sent back from electronic equipment into the mains. It applies to all electronic systems consuming more than 75 W.

Vicor says that the new VI BRICK AC/DC front-end module is compatible with a wide variety of downstream DC/DC converters, including its portfolio of high-density, high-efficiency VI Chip and VI BRICK converters. The VI BRICK AC/DC front-end is offered in three temperature grades: consumer (–20° to 100°C), telecom (–40° to 100°C), and military (–55° to 100°C).

Other choices

The race to deliver complete AC/DC front-ends for distributed power has become crowded, with contestants including Emerson Network Power, GE Energy’s Lineage Power, and TDK Lambda, just to name a few.

Emerson Network Power for example, produces a 3,000 W, compact, high-density AC/DC front-end for telecom system integrators. Labeled HPS3000, it offers 48 V regulated output power at 62.0 A. In fact, it is rated for up to 3,000 W of total output power at 200 VAC input and 1,500 W at 110 VAC input. Featuring a compact 1U x 3U form factor, the HPS3000’s peak efficiency is 92 percent at 50 percent load. It provides a power density of more than 41 W/in³ and is constructed with same-side AC inputs and DC outputs for convenient rack configuration. Featuring hot-swap ability and N+1 redundancy, up to four HPS3000 units can be operated in parallel across a 1U 19 in. rack shelf to deliver 12 kW of total output power.

Digitally programmable and fully compatible with Emerson’s PMBus graphical user interface software, the AC/DC front-end is well protected against overvoltage, short-circuit, and overtemperature conditions. What is more, it complies with EN55022-B and FCC Part 15 Level “A” EMC standards for conducted noise, including all applicable immunity standards. It also carries UL/cUL60950 safety approvals and is fully compliant with RoHS directives.

Similarly, GE Energy’s Lineage Power offers the 2500 W CAR2548FP, an AC/DC front-end supply module for distributed power with 48 VDC output from a small 1U package. Like Emerson’s module, GE’s CAR2548FP is hot-swappable and N+1 redundant with built-in remote On/Off, remote sense, active current sharing, output voltage margining, overvoltage, over current and over temperature protection. There is also an optional remote I²C / PMBus interface. With respect to efficiency, the GE module surpasses the 80Plus Gold level efficiency standard, according to the supplier.

Recently TD Corp. announced that the TDK-Lambda model HFE2500-48 front-end power supply has been certified to the 80 PLUS Platinum level for redundant, server, and data center applications. The 80 PLUS performance specification requires power supplies to be 80 percent or greater energy efficient at 20 percent, 50 percent, and 100 percent of rated load with a true power factor of 0.9 or better.

For overall system efficiency, including the efficiency of point-of-load (POL) converters, distributed architecture has evolved to intermediate bus architecture, wherein 48 VDC is further reduced to 24 or 12 VDC using intermediate DC/DC bus converters. Consequently, many of these suppliers are also offering AC/DC front-ends with 12 or 24 VDC regulated output. This eliminates the intermediate DC/DC stage and further boosts system efficiency and density.

Further reading

- “AC-DC Front End Sparks New Trends Density, Efficiency and Flexibility,” How2Power Today, December 2012

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国