Building Automation Systems Benefit from the Oldest and Newest Microcontrollers

投稿人:DigiKey 欧洲编辑

2015-11-05

Building automation goes beyond convenience; it introduces an entirely new way to improve efficiency into every aspect of our lives. As such, it will come to be seen as essential in assisted living, personal and property security, and energy efficiency. The concept has been around much longer than the IoT, of course, but it’s arguably recent trends like IoT and Big Data, coupled with more established but equally progressive developments in the distribution of utilities — empowered by Smart Meters — that will provide the ideal backdrop to take Smart Buildings to the next level.

Established technology

Long before the idea of connecting everything became a reality, data has been shared between services within buildings, to coordinate and control them. These Building Automation Systems (BAS) have evolved over the last three decades; from disparate, bespoke solutions that could be difficult to extend or maintain, to systems based on industry standards that invite interoperability.

As a result, while there may still be no definitive exemplar, such systems now display an increasingly common topology; a Building Management System sits above a Building’s Control Systems, which in turn oversee Zone Controllers that will be monitoring a number of end-nodes. This hierarchy dictates a need for a common network infrastructure and protocol. The physical interface may vary between the various layers; Ethernet may be prevalent at the BMS level, while it may come as no surprise that low cost and low power wireless protocols such as ZigBee and Bluetooth are emerging as the favorites at the node level.

However, a BAS has specific needs from each of its ‘actors’ and, therefore, they need to be able to communicate in a consistent and reliable way. In order to achieve this, the industry has largely standardized on the BACnet protocol, which is able to run over a variety of wired or wireless connections. The BACnet standard defines a way to communicate over Ethernet, RS-485, RS-232 and other protocol standards, including ARCNET and LonTalk, as well as the protocols that enable web services, such as UDP, IP and HTTP. As such, it has effectively become the common thread that runs through the various layers of a BAS.

Importantly, BACnet is equally at home on a large application processor as it is on a low power microcontroller, meaning it can be deployed in the smallest of nodes.

Sensor nodes

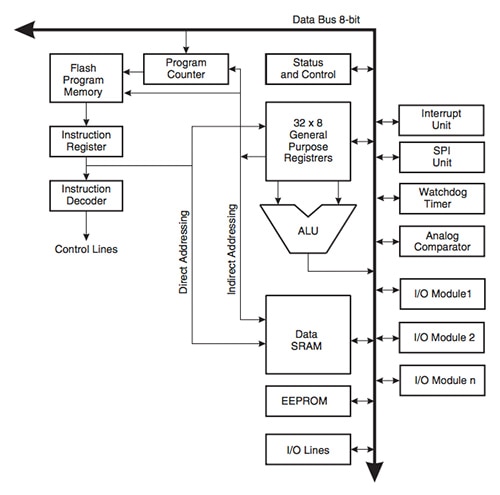

It is possible to add BACnet capability to a range of microcontrollers, such as those based on the Cortex-M3 core, or even simpler 8-bit devices such as Atmel’s AVR ATMega644P family. The core in this device offers thirty-two general purpose 8-bit working registers, all of which are directly connected to the ALU (Figure 1) and it forms the basis for an open-source BACnet development kit (Reference 1).

As well as the RISC core delivering up to 20 MIPS at 20 MHz, the ATMega644P offers a range of peripherals that would enable its use as a node device in a BAS, such as six PWM channels and an 8-channel 10-bit ADC, along with a number of serial interfaces (Figure 2). This would make it useful in nodes monitoring access or occupancy, for example, where the local computing demands are relatively low.

Figure 1: The ATMega644P RISC core offers thirty-two 8-bit general purpose registers directly connected to the ALU.

Figure 2: The ATMega644P offers a number of peripherals that would enable to be configured as a sensor node in a Building Automation System.

For applications that require a little more local processing, a more capable MCU may be required.

In this scenario, something like the ADuCM360s from Analog Devices may be more appropriate. Based on the ARM Cortex-M3 core, it features a more capable core but, importantly, a more sophisticated mixed-signal block, as shown in Figure 3.

Figure 3: The ADuCM360 from Analog Devices integrates a precision data acquisition system alongside the ARM Cortex-M3 core.

With dual 24-bit ADCs, it can support six differential or eleven single-ended input channels. It also features programmable sensor excitation sources and has been designed specifically for applications that include automation and process control, and smart sensor systems. The data acquisition system can reach 3.9 k samples/s and is designed to interface directly to precision sensors in battery-powered applications. On-chip firmware supports in-circuit programming over the serial interface, and UART non-intrusive emulation is also supported.

Display technology

As Building Automation Systems become more sophisticated, so too will the nodes around them; from simple, unobtrusive sensors to devices intended to interact more directly with people. This introduces additional requirements on the MCU, such as the ability to interface to or drive a display, probably with some form of user interface, such as capacitive touch sensing. The need to interface to other sensors will increase, as will the demand to perform more sophisticated pre-processing locally at the node.

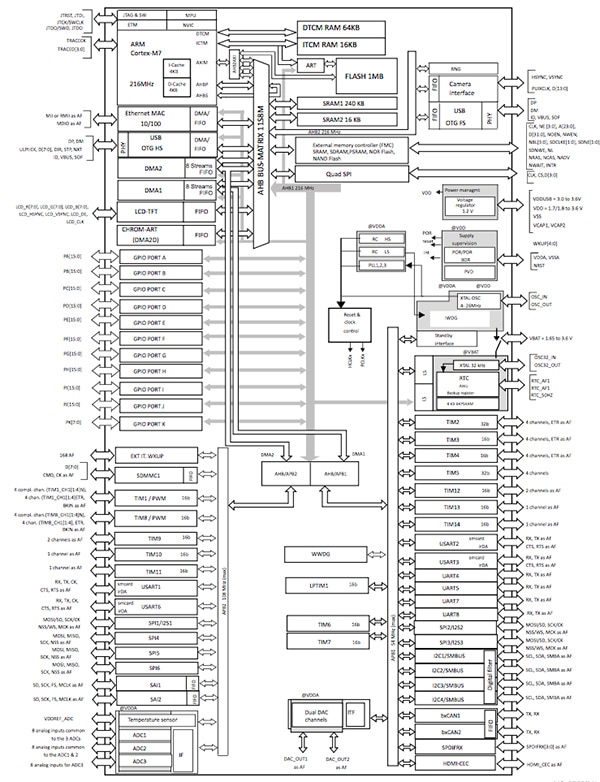

All of this points to more powerful MCUs, something that ARM has been cultivating in the form of its Cortex-M technology. The most recent addition to the Cortex-M family is the Cortex-M7 core, and the first device to market, is the STM32F7 family from STMicroelectronics. The core represents a significant development in the Cortex family; it offers a six-stage dual-issue pipeline with dynamic branch prediction and supports a set of DSP instructions that offer more efficient signal processing and complex algorithm execution. A single-precision floating-point unit is also included, yet the core remains binary-compatible with the Cortex-M4 family. Figure 4 shows a block diagram of the STM32F745xx and STM32F746xx family.

Figure 4: Block diagram of ST’s STM32F745xx and STM32F746xx Family.

In addition to the core, ST has integrated an LCD-TFT display controller for directly interfacing to a range of LCD and TFT panels up to XGA (1024x768) resolution. To complement the core’s functionality, ST has also added its own Chrom-ART Accelerator; a graphic accelerator that offers advanced bit, blitting, row data copy, and pixel format conversion. A digital camera interface is also included, which is capable of connecting with CMOS sensors and camera modules though an 8-bit to 14-bit parallel interface, to receive video data. The interface can sustain a data transfer rate of up to 54 Mbyte/s at 54 MHz.

Conclusion

The concept of Building Automation has been around for many years, and as such it typifies the synergy between technology and an end-market. As technology has evolved, so too has the concept and now, along with the IoT, the potential for smart buildings is really gaining pace. As nodes, enabled by MCUs become more ‘intelligent’, consumers will benefit from a more secure and rewarding level of automation and this in turn will generate even greater demand.

Perhaps atypically, however, it is still a sector that can make use of more established MCUs; 8-bit devices still have a place in the BAS node, while the very latest devices based on cutting-edge cores will undoubtedly become a popular solution for nodes that will offer a greater user experience.

One thing seems certain, the MCU will, once again, be a critical element in the further evolution of Building Automation Systems.

References

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国