Battery-Charging Controllers for Energy Harvesters

投稿人:电子产品

2013-05-01

Whether your energy harvesting application uses large solar panels with high voltages and currents or, more often the case, must make do with minute amounts of power derived from various other ambient energy sources, one thing is almost certain: some type of energy storage is on board, whether in the form of a small rechargeable lithium ion battery, a supercapacitor, or solid-state energy storage technology.

For the engineer this means that not only do we need to design circuits to harvest and convert ambient energy, but we also have to include an energy-harvesting interface (and protection circuitry) as well as a charge controller.

This article looks at single chip energy harvesting devices that also provide some form of charge control. It discusses the different conditions under which energy can be extracted as well as what to expect when trying to squeeze power out of the ambient environment. Finally, the article will present some typical integrated solutions for small-sized low-power energy-harvesting designs.

Sleep and startup

Low power memory and micros can sit idle and asleep for long periods of time, drawing only nanoamperes. During sleep cycles, the energy harvesting techniques employed should provide more power than the sleeping circuits require. When enough excess energy has been accumulated to do something useful, such as charging a capacitor or battery, the micro can wake up.

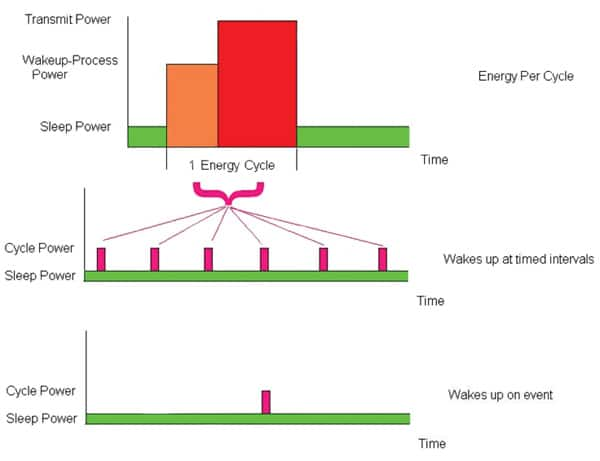

In some cases, the amount of energy needed for the task at hand is easily determined. For example, Figure 1 shows a sampling application in which a wireless low power sensor wakes up every so often, takes a reading, transmits it, and then goes back to sleep. It can be programmed to slowly draw microamperes from the environment to maintain a charge on a capacitor or battery.

Event driven designs are trickier. If an event needs to be responded to quickly, then the micro needs to be awakened more frequently to assure the necessary response time. The more it wakes up, the more energy it burns, and the more of a demand it creates on your harvesting system and storage cell.

In this case, to save energy, instead of the polling technique described above, an interrupt technique allows longer sleep time, saving more energy. Many micros today have threshold and event detection capability, letting the micro stay asleep until the event. With clever designs, the demands on the harvester can be lessened.

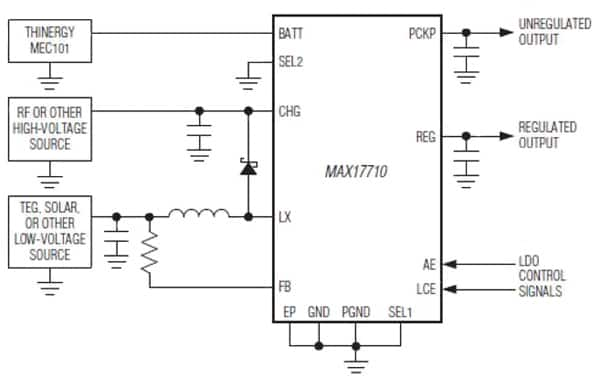

Overall, energy harvesters not only have the challenge of gathering energy, they also need to condition that energy and meter it out to batteries and the circuit at hand. One effective design comes from Maxim with its MAX17710 Energy Harvesting Manager IC (Figure 2).

Note the two inputs in Figure 2; one for high-voltage sources like piezoelectric or inductive RF based coupling inputs, and one for lower-voltage, higher-current sources like solar cells. Also internal to the IC is under-voltage protection for lithium batteries and a charger overvoltage shunt circuit. In either case, battery protection assures that it will not overcharge and shorten its operating life.

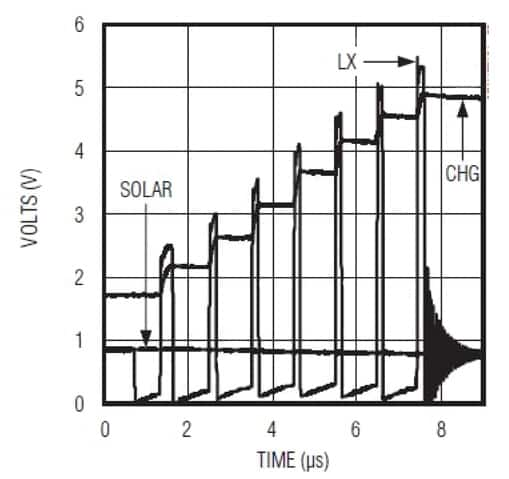

This part includes an internal boost regulator featuring a boost startup circuit that steps up voltages as low as 0.75 V (Figure 3). This allows extended harvesting of energy from, for instance, a solar panel that is shaded or exposed to dwindling light levels. The internal low-dropout regulators feature a selectable regulated output voltage of 3.3, 2.3, or 1.8 V. An unregulated output is also provided. For more information, take a look at the Reference Design for a solar-based thin film battery charger available from Infinite Power Solutions.

The Reference Design IC is designed to work very specifically with the THINERGY® MEC series of batteries, also from Infinite Power Solutions. These rechargeable lithium 4.1 V cells come from 130 µAh to 2.2 mAh ratings with heights of only 0.2 mm. When a single source partnership of this type is undertaken, you can expect a tightly coupled and well engineered solution. Further design assistance is offered in the form of Infinite Power Solutions’ two applications development kits and a wireless environmental sensor board that senses humidity, light level, and temperature.

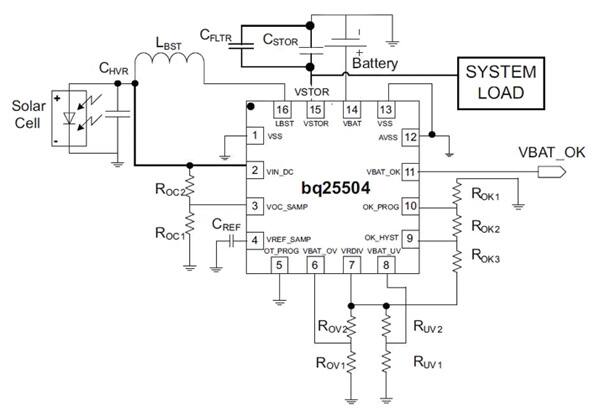

Another noteworthy part comes from Benchmarq; a division of Texas Instruments. The BQ25504 is an energy-harvesting interface chip that allows continuous energy harvesting from low-input sources (80 mV in this case). Instead of being pegged to one specific battery type it lets you program the undervoltage and overvoltage levels with external resistors to more easily adapt it a variety of battery types (Figure 4). Hysteresis levels can also be programmed allowing you to tailor the BQ25504’s output to charge and control a variety of batteries or supercaps.

Some nice features of this part are a battery-good output pin and a signal that lets an embedded micro know that power loss is imminent. This part can also be used as a switch to enable or disable system loads. Benchmarq/TI provides an Eval Board for testing and evaluating the device. It also provides a Power Management for Energy Harvesting Product Training Module as well as a Reference Design for a low-power boost charger.

Stepping up

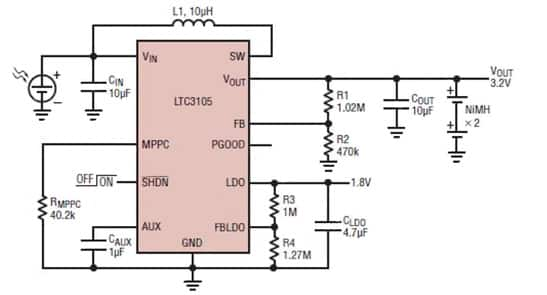

Some general-purpose switching power devices have enough flexibility to directly target energy-harvesting applications. A case in point is the Linear Technology’s LTC3105 DC/DC converter chip with metered outputs. As a featured member of Linear’s Energy Harvesting Power Products, it efficiently steps up from voltages as low as 225 mV and provides a 6 mA output from its internal LDO specifically for low-power embedded micros.

Some nice feature of the Linear Technology parts are the wide input voltage ranges (0.225 to 5 V) and the wide output charge voltage adjustable range (1.5 to 5.25 V). It also has a Power Good output signal and an adjustable LDO output from 1.4 to 5 V. What’s more, it has a shutdown pin to allow it to operate as a power switch and a sensor for temperature compensation.

Key is its ability to program the power point setting (using external resistive voltage dividers). Energy devices like solar cells and thermoelectric elements have optimum points of maximum power delivery. Peak current limits are automatically adjusted to maintain operations at the optimum voltage level and extract the most energy.

Several reference designs are illustrated in the LT3015’s documentation, including a single cell photovoltaic NiMH trickle charger (Figure 5).

Batteries and charge controllers under one roof

An interesting technology from Cymbet is its family of solid-state batteries and a family of Energy Harvesting and Charge Controlling chips to support them. For example, the CBC915 Energy Processor chip boasts the ability to use any type of energy-harvesting format to achieve high efficiency energy conversion and conditioning. CBC915 also offers built in temperature compensated charge control.

Cymbet provides a useful Product Training Module tutorial on its solid-state batteries and charge controllers as well as energy management and energy-harvesting demo and eval kits, so you can quickly and easily evaluate this technology at low cost and with low risk. The TechZone article “A Closer Look at Energy Harvesting: The Cymbet Energy Harvesting Development Kit” provides a review of the Cymbet dev kit.

In conclusion, energy harvesting is promising to make a new class of very-low-power and self- powered devices a reality. As energy storage devices continue to deliver faster charge, higher capacities, and longer lifecycles, more suppliers can be expected to contribute power management ICs to create a seamless energy-harvesting solution.

You’ll find all of the parts, datasheets, training materials, and development kits mentioned here on the DigiKey website.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国