Electrolytic and Ceramic Capacitors

2023-11-28 | By Antonio Velasco

Let's talk about capacitors: the tube-like components that you'll find on almost every board.

We'll mainly talk about the two types of capacitors (or caps, as the "new gen" calls it), but we first need to establish what they are. Think of them as tiny electronic reservoirs that store and release electrical energy. They consist of two conductive plates separated by an insulating material, called a dielectric.

When voltage is applied across the plates, they accumulate an electric charge, similar to filling a bucket with water. When the voltage is removed, or the circuit requires a burst of energy, capacitors release their stored charge, supplying it to the circuit like a water bucket emptied.

Now that we've established what they are, let's talk about the two most popular types: electrolytic and ceramic.

Electrolytic Capacitors

Electrolytic capacitors typically have very high capacitance values, which means they can store large amounts of electrical energy. They're often used when you need a substantial reservoir of charge, such as in power supply circuits or audio systems.

They also tend to have a large range, going from microfarads (µF) to farads (F). These values are on the larger end of the capacitance spectrum.

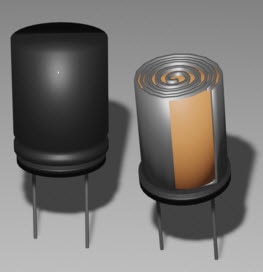

These are the capacitors that have a cylindrical shape resembling a tube. You might notice that one side is shorter than the other--this indicates polarity, something unique to electrolytic capacitors. Reversing them or mixing them up can lead to the capacitors failing to work, or in some cases, exploding. Ensure that you pay attention to the markings on your cap.

You can see inside that the plates are essentially just rolled up in a nice little coil. This is much unlike the next capacitor we'll talk about, which is the ceramic capacitor.

Ceramic Capacitors

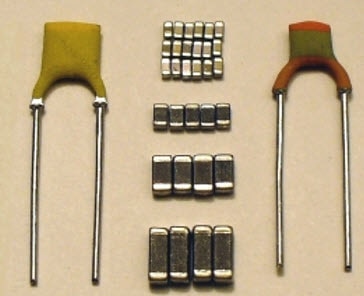

Ceramic capacitors are much smaller and compact, looking like a little plate at the end of a pair of leads:

Their small size makes them optimal for several applications, and additionally, they are non-polarized, allowing you to connect them either way.

Looking inside the caps, you'll find numerous plates next to each other as opposed to a rolled-up plate like the electrolytic capacitor. This smaller size (and thus surface area) means that they typically won't have as high of a capacitance value, ranging instead from picofarads (pF) to microfarads (µF).

Choosing Between the Two

- The most obvious difference will come in how much capacitance your project requires. If you require a substantial reservoir of energy, electrolytic capacitors are the way to go. For smaller tasks or high-frequency applications, ceramic capacitors are often more suitable.

- It is also important to consider your environment. It's no secret that electrolytic capacitors tend to be larger--so that's something to consider, but another aspect that you might need to think about is the temperature. Ceramic capacitors tend to be more temperature resilient as it is just a few plates. The rolled-up electrolytic capacitor, however, is more susceptible to certain temperatures and will break down.

- Another aspect might be frequency, where ceramic capacitors have a faster frequency response time. Anything that involves radio comms or data transfer might benefit from a ceramic capacitor. They are also useful in filtering noise and maintaining voltage levels near integrated circuits.

To summarize, electrolytic capacitors are great for large capacitance values across a wide range, which tend to be in a stable environment. Ceramic capacitors are great for smaller capacitance values that can be in a variable environment or a much smaller space. Ensure that you evaluate your needs to select the right one!

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.