权衡外壳材料的利弊

2024-10-03

外壳有多种样式、尺寸和形状,但外壳材料往往才是采购新产品时的首要考虑因素,也可以说外壳材料是影响外壳性能的最大因素。常用材料的相关知识对于规划、采购和维护电气和电子组件至关重要。

一般来说,外壳材料可分为金属材料和非金属材料两类。

非金属材料

大部分非金属外壳由塑料制成,通常为 ABS 或聚碳酸酯,但非金属材料也包括玻璃纤维。

非金属材料可透射频 (RF) 波,是需要轻松收发信号的无线通信设备的理想之选。但这也是把双刃剑,如果设备需要隔离电磁干扰 (EMI) 和射频干扰 (RFI),这一特性就会带来不利影响。

ABS

丙烯腈-丁二烯-苯乙烯 (ABS) 是一种低成本热塑性塑料,易于加工和成型。ABS 是室内用途的优选塑料,虽然相对经济,但却具有优异的抗冲击性、耐热性和多功能性。通用 ABS (GPABS) 是最经济的类型,另外还有阻燃 ABS (FRABS),其阻燃性能达到中高水平 (UL 94V-0)。

ABS 外壳通常为黑色、灰色或白色,但黄色、红色和蓝色等彩色外壳也不少见。ABS 易于加工和改造。遗憾的是,这种材料并不适合高强度用途,而且很难使 ABS 透明。

图 1:Hammond 的 1551MINI 系列 ABS 塑料外壳。由于 ABS 不可能完全透明,因此半透明或“磨砂”ABS 很常见。(图片来源:Hammond Manufacturing)

图 1:Hammond 的 1551MINI 系列 ABS 塑料外壳。由于 ABS 不可能完全透明,因此半透明或“磨砂”ABS 很常见。(图片来源:Hammond Manufacturing)

聚碳酸酯

聚碳酸酯是塑料世界的明星。这种材料具有出色的抗冲击性、较宽的工作温度范围和优异的抗紫外线破坏能力,是许多室外、高冲击和海洋应用的优选塑料。抗紫外线聚碳酸酯可防止因日晒而褪色和变脆,而且天然透明。因此,聚碳酸酯经常用于眼镜片、赛车挡风玻璃以及高质量外壳等产品。聚碳酸酯具有高阻燃等级。不出所料,聚碳酸酯的经济性不如 ABS,尤其是在项目初期,但从长远来看,聚碳酸酯即使在恶劣的条件下也经久耐用,这样反而能够节省成本。

图 2:Hammond 的 1591T 系列透明聚碳酸酯塑料外壳。(图片来源:Hammond Manufacturing)

图 2:Hammond 的 1591T 系列透明聚碳酸酯塑料外壳。(图片来源:Hammond Manufacturing)

玻璃纤维

玻璃纤维增强聚酯简称 FRP 或 GRP,由玻璃纤维增强聚酯塑料组成。与聚碳酸酯一样,FRP 也适合室外使用,具有优异的抗冲击性和较宽的工作温度范围,甚至比聚碳酸酯还要宽。不过,FRP 可能会因紫外线照射而褪色。由于 FRP 的构成,其在切割时会使玻璃微粒分散,因此改造时需要专门的 PPE(个人防护用品)和工具。

聚碳酸酯和 FRP 都具有优异的耐化学性,都非常适合在含盐环境中使用。FRP 耐溶剂、稀酸和稀碱。聚碳酸酯对酸、某些溶剂和碱的耐受性也较好。选择材料之前,务必要对具体的危害进行研究。

图 3:玻璃纤维增强聚酯外壳,Hammond 零件编号 1590ZGRP084。(图片来源:Hammond Manufacturing)

图 3:玻璃纤维增强聚酯外壳,Hammond 零件编号 1590ZGRP084。(图片来源:Hammond Manufacturing)

金属材料

与非金属材料相反,由金属制成的外壳对 RFI 和 EMI 具有更好的屏蔽性。金属与金属之间的接触对于完全屏蔽和接地至关重要,这是在外壳内处理电气设备时确保安全的必要过程。金属材料一般可用于室外用途,并且具有优异的抗冲击性。

对于金属而言,注意电化学腐蚀(也称异种金属腐蚀)非常重要。如果两种不同的金属相互接触,“碱性”更强或更容易放弃电子的金属将开始加速腐蚀,从而造成结构和外观损伤。例如,用户应注意不要在不锈钢外壳上使用镀锌螺丝或镀锌钢连接件。

铝

铝是一种有色金属,虽然重量相对较轻,但却很坚固。除了有铝板、挤压铝和压铸铝等各种形式外,铝的特性也因使用的合金不同而不同。合金由基材(铝)和其他金属或元素组成。有些合金比其他合金更坚固,或更抗拉,或更能接受某些表面处理方式,等等。

铝易于加工和成型,是成本最低的金属外壳材料。

压铸铝

压铸铝外壳通过将熔融金属倒入成型模具(也称为型腔)来生产。压铸件最适合用于中小型外壳,而大型产品往往采用金属板,而非铸造金属。这种工艺生产速度快,而且生产出的产品始终如一。压铸外壳以及注塑成型塑料外壳都有一个称为脱模角的特性。盒壁必须略微向外倾斜,以便外壳能够从铸件上正确脱离。因此,压铸铝外壳的壁会有几度的倾斜。

图 4:厚壁压铸铝外壳,Hammond 零件编号 1590Z110。(图片来源:Hammond Manufacturing)

图 4:厚壁压铸铝外壳,Hammond 零件编号 1590Z110。(图片来源:Hammond Manufacturing)

挤压铝

挤压也涉及熔融铝和模具,但挤压铝不是填充型腔,而是强制穿过模具形成特定形状,从而得到很长的挤压件,然后再切割成不同尺寸。挤压铝外壳通常由挤压管和金属或塑料端盖组成。挤压可切割的大件管材对制造商有利,因为制造商可以保持管材库存,并根据需要提供各种长度的外壳。

Hammond 提供的挤压铝外壳均经过阳极氧化处理。阳极氧化是一种增加外壳氧化层厚度的工艺,可使表面更加耐用。阳极氧化可呈现各种颜色。有些铝合金可以进行阳极氧化处理,有些则不行;而 Hammond 的挤压外壳可以进行阳极氧化处理,压铸铝外壳则不行,只能进行粉末喷涂。

图 5:经过蓝色阳极氧化处理的挤压铝外壳(已组装)。Hammond 零件编号 1455L1201BU。(图片来源:Hammond Manufacturing)

图 5:经过蓝色阳极氧化处理的挤压铝外壳(已组装)。Hammond 零件编号 1455L1201BU。(图片来源:Hammond Manufacturing)

图 6:图 5 中经过蓝色阳极氧化处理的挤压铝外壳的拆卸状态。(图片来源:Hammond Manufacturing)

图 6:图 5 中经过蓝色阳极氧化处理的挤压铝外壳的拆卸状态。(图片来源:Hammond Manufacturing)

铝板

铝板可以切割和折叠,以制作外壳和面板。挤压件和模具受到工具特性和尺寸的限制,而折叠金属板则与它们不同,可以制作出无数种外壳设计。铝板,尤其是较薄的铝板,不能承受特别大的重量,如果超重,铝板可能会弯曲或翘曲。

图 7:Hammond 的 1444 系列折叠铝外壳内部。(图片来源:Hammond Manufacturing)

图 7:Hammond 的 1444 系列折叠铝外壳内部。(图片来源:Hammond Manufacturing)

钢

钢是许多行业广泛使用的可靠材料。钢是一种铁合金(由铁与碳结合而成)。钢板用于制造外壳和面板,根据不同的应用,有多种钢材可供选择。钢比铝重,其成本更高,尤其是不锈钢。

软钢

软钢也称为“低碳钢”,其碳含量低于标准钢,更易于成型和焊接。低碳钢成本低,用途广泛,但除非经过表面处理,否则会因天气影响而氧化。这就是软钢外壳采用粉末涂层表面处理而不锈钢或铝外壳则采用本色表面处理或较少表面处理的原因。天然软钢可用于内部面板,因为它们不会暴露在自然环境中。

图 8:经过浅灰色粉末涂层表面处理的软钢外壳,Hammond 零件编号 ST12126LG。(图片来源:Hammond Manufacturing)

图 8:经过浅灰色粉末涂层表面处理的软钢外壳,Hammond 零件编号 ST12126LG。(图片来源:Hammond Manufacturing)

镀锌钢

镀锌钢通过将钢浸在锌涂料中制成。这样可以保护钢的富铁表面不被迅速腐蚀。镀锌钢对于具有超强腐蚀性的化学品或海洋环境耐受性不佳。镀锌钢是内部面板和通用室内商用外壳的常用材料。经过粉末喷涂后,镀锌钢可在室外光照条件下使用。

不锈钢

不锈钢是一种含铬的铁合金,具有耐腐蚀性。通过添加其他元素,可以制造出不同牌号的不锈钢。不锈钢不易生锈,无需进行表面处理。不锈钢具有很强的耐酸性、耐碱性和耐溶剂性,在室外也有很好的表现,而且易于清洁,因此非常适合需要经常冲洗外壳的卫生环境,例如医疗或食品饮料应用场合。

最常见的两种不锈钢牌号为:

- 304 - 这是最常见的不锈钢牌号。

- 316 - 这是更专业的牌号,具有所有上述不锈钢优点,并且额外添加钼元素,因此具有更强的耐腐蚀性。316 不锈钢在海洋环境中表现出色。

图 9:独立式不锈钢外壳,Hammond 零件编号 HN4FS726036SS。(图片来源:Hammond Manufacturing)

图 9:独立式不锈钢外壳,Hammond 零件编号 HN4FS726036SS。(图片来源:Hammond Manufacturing)

评级和材料

外壳的评级和材料密切相关,因为 NEMA、UL 和 IP 等评级系统根据外壳在各种条件下的性能来评估外壳。

NEMA - NEMA 是工业和电气外壳最常用的评级系统,NEMA 类型描述外壳是用于室内还是室外、是否耐腐蚀以及如何抵御水和灰尘等危害。一些常见的 NEMA 类型包括:

- 12 和 13 - 室内使用,有一定的防尘和防滴水能力

- 3R - 室内或室外使用,防尘、防潮湿天气(雨、雨夹雪、雪)

- 4 - 室内或室外使用,具有优异的防尘、防潮湿天气、防溅水或防水管引水能力

- 4X - 与 4 类似,但耐腐蚀性增强

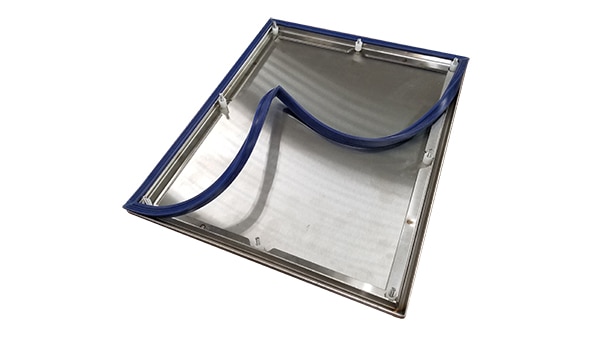

图 10:Hammond 的 HYW 系列不锈钢外壳的门上有一个蓝色卫生硅胶垫圈。(图片来源:Hammond Manufacturing)

图 10:Hammond 的 HYW 系列不锈钢外壳的门上有一个蓝色卫生硅胶垫圈。(图片来源:Hammond Manufacturing)

侵入防护 (IP) - IP 等级由国际电工委员会 (IEC) 确定。IP 是电子器件外壳领域的典型术语,但 IP 等级和 NEMA 等级之间存在交叉。IP 等级的第一位数字与防尘性有关,第二位数字与防水性有关。一些常见的 IP 等级包括:

- IP54 - 防尘,防溅水

- IP65 - 最低防水等级,室外使用的最低建议等级,防尘,防喷水

- IP66 - 防尘,防强力喷水

- IP67 - 防尘,防暂时浸泡

- IP68 – 防尘,防长时间浸泡

UL 认证 - 通过 UL 认证的产品由独立实验室进行测试。认证外壳符合 UL 508A 所列标准。两次测试之间不得进水;否则,产品将无法通过 UL 认证。诸如材料一致性、工厂工艺、抗紫外线性以及可燃性等级之类的其他因素也在考虑之列。UL 认证是性能、质量和安全性的重要指标。

图 11:UL 认证聚碳酸酯外壳内部的 UL 标签,Hammond 零件编号 1554C2GYCL。(图片来源:Hammond Manufacturing)

图 11:UL 认证聚碳酸酯外壳内部的 UL 标签,Hammond 零件编号 1554C2GYCL。(图片来源:Hammond Manufacturing)

结语

设计电气或电子组件需要考虑很多因素,但希望这篇关于外壳材料和等级的概述文章能帮助您简化外壳的选择过程。

无论应用需要的是用于手持式开关的简易塑料盒,还是必须在码头上抵御咸湿空气的坚固不锈钢柜,外壳无疑都是任何组件的重要组成部分。

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。