Using the PMbus to Watch for Power Problems

投稿人:DigiKey 欧洲编辑

2016-05-31

The shift to Industry 4.0 and the Industrial Internet of Things (IIoT) sees individual elements of manufacturing control systems adopt greater levels of local autonomy to allow real-time adaptation to market needs. Maintaining throughput in this environment will depend on those local controllers exhibiting a high degree of reliability. The ability to recognize fault conditions is key to maintaining high availability and continuous production and this extends down to the power supply, particularly as power converters tend to suffer a higher failure rate in the field because of the high stresses on the components. Advanced diagnostics and the ability to hot swap power converters over on running systems are both important to maintaining uptime.

The PMbus not only provides a means to monitor failures and the signs of problems in power converters and related circuitry but also to provide a standard interface for hot-swap control. First published as a standard in March 2005, the PMbus is derived from the System Management Bus (SMbus) that was developed to control processor boards in data-center servers.

Both SMbus and PMbus are based on the same the two-wire I2C bus but PMbus adds an alert line that allows any node on the bus to interrupt the system master. The use of the alert line reduces the need for that master to continuously poll slaves for updates. This is an important characteristic as it helps reduce the software overhead on the microcontrollers used in high-reliability systems.

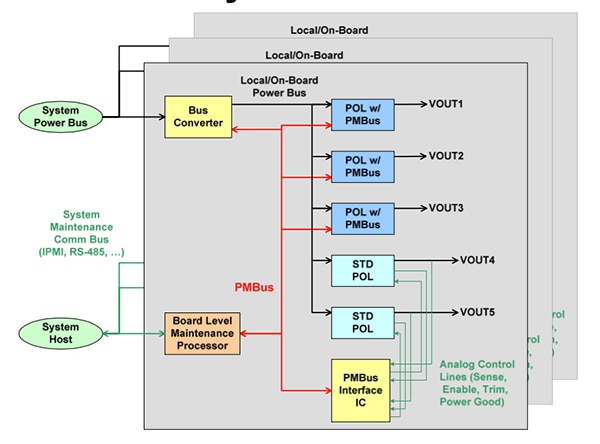

Figure 1: Use of PMbus within a system-level environment. [Source: PMbus/SMIF]

Using the serial bus, the PMbus can manage a number of power converters on a board, providing finer-grained control than is possible using conventional design approaches. The level of management that PMbus provides makes it possible to activate each of the converters in a sequence. The controlled startup avoids disruption to the main power bus such as excessive voltage sags. In a similar fashion, PMbus provides commands to shut down power converters automatically ready for a hot-swap event. To help indicate to technicians and maintenance staff when a plug-in power supply should be exchanged for a replacement, the PMbus relays vital monitoring and control data to a system-management controller.

The PMbus packet structure is simple but is capable of handling more than 100 different power-management commands, with room for expansion into the current 1-byte command space and even further through a 2-byte extended-command structure. Two commands are used to control the startup sequence of power converters managed by a PMbus controller. TON_DELAY programs a time for the converter to wait after receiving the control signal before starting to provide power to downstream devices. Similarly, TOFF_DELAY is used to control how long the converter waits before disabling power to its downstream components.

Further, PMbus controllers can provide fine-tuned control over output voltage. The TON_RISE and TON_FALL commands determine how quickly voltage is increased and reduced, respectively, once a TON_DELAY or TOFF_DELAY command is received.

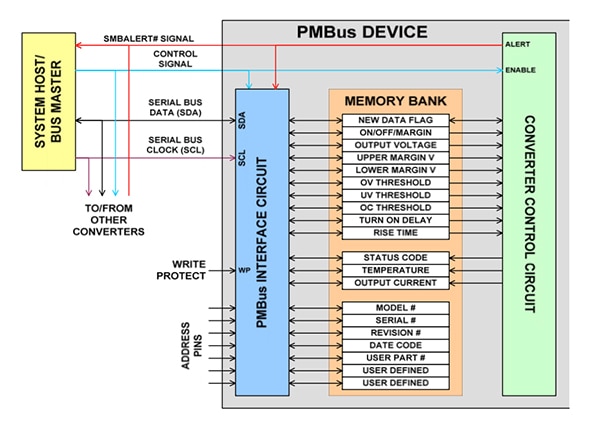

A number of command and message codes provide information that is vital for fault management. Messages include IOUT_ OC_FAULT_LIMIT, IOUT_OC_FAULT_ RESPONSE, IOUT_OC_WARN_LIMIT, OT_WARN_ LIMIT, OT_FAULT_LIMIT and OT_FAULT_ RESPONSE. The messages allow converters to report overcurrent, overvoltage and overpower on the input and output as well as temperature limits being exceeded. The system controller in a high-reliability system should be programmed to interpret and handle these fault indications. The response may be to record the fault in a log and, in an IoT-type environment, relay the fault to a server that is responsible for coordinating equipment.

Alternatively, the controller can take direct action. It can shut down the affected converter and allow a hot spare to provide power until a replacement is installed. Or the controller may power-cycle or attempt to restart the converter. The Commands IOUT_OC_ FAULT_LIMIT and IOUT_OC_FAULT_RESPONSE let the user program the overcurrent trip threshold and determine how the converter should respond when the overcurrent limit has been exceeded. Converters may also have hardwired responses.

Figure 2: Typical implementation of PMbus status and control registers in a compliant device to support commands and status codes. [Source: PMbus/SMIF]

In the case of the LTC3882 polyphase DC/DC regulator controller made by Linear Technology, an overcorrect condition is detected by a supervisor comparator on each of its pulse-width modulation (PWM) outputs. If the instantaneous current for a particular channel exceeds the limit set by the IOUT_OC_ FAULT_LIMIT command, the controller immediately disables the top FET and the bottom FET is kept on for the remainder of the cycle.

Further changes in operation are programmed using IOUT_OC_ FAULT_RESPONSE. The hardware response may be to attempt to continue normal operation, to restart the channel and to keep restarting for up to the interval specified by the MFR_RETRY_DELAY command or to shut the channel down. If the system controller determines that the fault is likely temporary, it can reset using a command such as CLEAR_FAULTS. If the fault immediately reappears, the system controller may choose to take further action or reprogram the fault response such that the channel attempts to restart and then shut down if the fault does not clear.

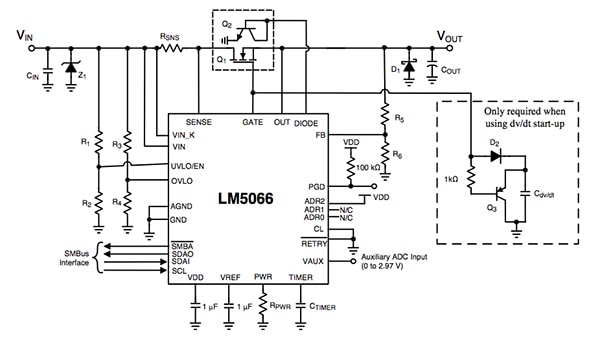

Through its command structure and in conjunction with compliant controllers, PMbus enables the safe swapping of boards in a running system. A hot-swap controller such as the Texas Instruments LM5066 manages power delivery to the rest of the board, ensuring that devices do not experience a high inrush current when the connectors mate or suffer sudden, potentially damaging shifts in voltage at high current when a board is removed.

Even with hot-swap logic control, care needs to be taken in selecting and integrating the power-switch FET that controls power delivery to the rest of the board. The circuit design needs to ensure the circuit behaves correctly when the output is suddenly shorted to ground when the hot swap is on – a hot-short – and during the power-up of a board when the output and ground are shorted, which is known as a start-into-short.

A key characteristic of the hot-swap circuit is the size of the output capacitor used to help smooth power delivery to the rest of the board. When charging this capacitance, the FET’s total energy dissipation is the energy it can store. So input voltage and capacitance determine the stress experienced by the FET. Further considerations are the maximum load current and thermal properties of the board itself, as this determines the level of on-resistance that the MOSFET should exhibit. It will need to be low enough to maintain a steady-state temperature below the FET’s maximum thermal rating.

The FET needs to be able to handle the maximum system voltage plus transients. For a 48 V system, a 100 V FET should be adequate. Further the safe operating area needs to be able to handle the hotswap conditions of startup, hot-short and start-into-short. Programmable SOA protection provided by the LM5066 sets the maximum power the FET is allowed to dissipate under any condition. A programmable fault timer is present that can be set to avoid nuisance trips and limit the duration of load events. A cycling mode is supported to help ensure startup after a power supply has been plugged in.

Figure 3: Circuit diagram of the TI LM5066 and its associated hot-swap FET.

In addition to circuit protection, the LM5066 supplies real-time power, voltage, current, temperature, and fault data to the system management host using the PMbus. Integrated telemetry enables intelligent power management functions such as efficiency optimization and, in addition to fault detection, provides features such as current, voltage and power averaging and peak power measurement to improve system diagnostics.

A further important feature supported by PMbus for high-reliability systems is its support for voltage margining, which can be used on devices such as the LTC3882. Voltage margining is typically employed to determine whether IC performance will suffer excessively due to minor variations in supply voltage. Devices that are operating close to their limits and at risk of failure can be detected during this process and replaced before leaving the production facility. Automated margining makes it possible to perform in-field tests to detect problems caused by ageing.

Margin testing using traditional power supplies is difficult to perform. It can demand the temporary fitting of resistors to DC/DC converters to force their output voltage to vary outside the nominal range. PMbus voltage margining commands – VOUT_MARGIN_HIGH and VOUT_MARGIN_LOW – allow the tests to be performed automatically, through a pair of commands that can force the voltage either higher or lower than normal settings.

Taken together the rich set of commands supported by PMbus for power converter testing, control and fault monitoring will allow industrial systems to improve their reliability and resilience and help support the transition to an IIoT infrastructure.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。