使用微型模制电感器可节省空间、降低损耗并提高电源完整性和效率

投稿人:DigiKey 北美编辑

2024-08-15

电感器是电压转换器和稳压器设计中的关键元器件。由于具有能量储存和回收作用,因此几乎所有调节功率的电路中都有这些器件的身影。随着应用趋向于更小、更紧凑的设计,而且必须不断提高能效,设计人员在挑选电感器时需要更加审慎,才能顺应趋势并处理更大的电流。

降低功率损耗和提高效率在很大程度上依赖于电感器的设计和磁芯材料。例如,使用微型模制电感器可减少电感器体积,同时还能保留传统电感器的所有优点,并增强电磁干扰 (EMI) 屏蔽、提高功率密度、降低磁芯损耗。

本文先简要介绍电感器和电感。接着介绍 Abracon LLC 的微型模制电感器,并讨论其选型和应用。

电感器和电感

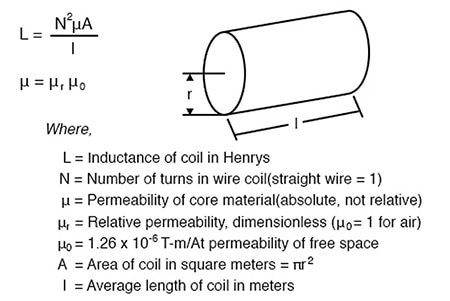

电感器是双端无源元器件,以磁场的形式储存和回收能量。其外形通常是缠绕在线圈上的绝缘导线。当向电感器施加电流时,线圈内会产生与该电流成正比的磁场。如果施加的电流发生变化,就会产生时变磁场,该磁场会在导体中产生电动势 (EMF)。感应电压的极性与产生该电压的电流变化相反。电感器的特性在于其电感值,即感应电压与电流变化速率的比值。电感的单位是亨利 (H),可以通过增加线圈匝数、加大横截面、缩短线圈长度或使用磁导率更高的磁芯来增加电感(图 1)。

图 1:决定线圈电感的因素。(图片来源:Abracon)

图 1:决定线圈电感的因素。(图片来源:Abracon)

磁导率是一种磁性特征,磁芯材料的磁导率越高,产生的磁通密度就越大,从而可以储存更多能量。因此,电感也与电感器磁芯材料的磁导率成正比。高磁导率磁芯可以在不降低电感值的情况下减小电感器的尺寸和重量,实现更小更轻的整体封装。

磁芯材料包括空气、铁、钢、铁粉、金属粉末、陶瓷和铁氧体。铁氧体是陶瓷材料,与氧化铁粉末和/或其他金属粉末结合在一起,形成一种高磁导率的磁芯材料。粉末磁芯使用磁性金属粉末与粘结剂和涂层混合而成。金属和粘结剂的选择,甚至混合物中的气泡含量,都会影响最终磁芯材料的磁导率。

电感器规格

功率应用中使用的电感器有几个关键规格,包括电感、直流电阻 (DCR)、饱和电流、温升电流、额定电流、自谐振频率 (SRF) 和品质因数 (Q)。

DCR 有时也称为线圈损耗,是直流电源电感器的实测电阻。由于导线的长度和横截面积不同,DCR 的变化与电感成正比。功率电感器的 DCR 通常为几十 mΩ,以确保较低的传导损耗。大多数情况下,DCR 会被指定为最大额定值。

随着通过电感器的电流增大,磁场也会成比例增强,直至达到饱和状态;此时,磁导率开始下降。电流增大超过此极限值时,会导致电感下降。饱和电流是指电阻导致标称电感值下降特定数值时的电流。功率电感器通常采用电感值下降 10% 至 30% 作为规格限值。

温升电流是指电感器外壳温度上升 40°C 时的直流电流。

额定电流规定为饱和电流或温升电流中的较低值,使电感器能在低于两限值中较低者的情况下工作。

SRF 是指电感器寄生电容的电抗等于感抗时的频率。此时,电感器作为并联谐振电路工作。净电抗为零,阻抗极高且完全是电阻阻抗。在功率应用中,电感器的工作频率通常低于其 SRF。

电感器的 Q 值是其效率的量度,是给定频率下其感抗与电阻的比值。Q 值越高,损耗越低,电感器的行为越接近理想电感器。

模制功率电感器

模制功率电感器是表面贴装器件 (SMD),利用模压技术将电感器线圈包裹封装起来。有别于传统绕线式电感器,模制电感器的磁粉材料被压入围绕导体的线圈外围的模具中。模压复合物,通常是金属粉末和粘结剂,确定电感器磁芯的磁导率。与铁氧体填料相比,金属粉末填料的饱和响应更柔和。其还能提供高效的磁屏蔽,从而减少磁通泄漏。模制电感器是适用于严苛环境的固体元器件,具有防潮、防尘、防冲击和防振动特性。因为没有层压磁芯,模制电感器不会发出噪声。简单的一体式结构具有出色的机械稳定性,而且结构紧凑、重量轻。

Abracon 的微型模制电感器采用 3 mm 以下的小型封装,提供模制电感器的所有优点。除了体型小巧外,微型模制电感器还具有高功率密度、低磁芯和传导损耗以及出色的 EMI 屏蔽等特性。

AOTA-B1412 和 AOTA-B2012 系列微型模制电感器的电感范围为 0.11 至 2.2 µH,封装尺寸为 1.4 x 1.2 mm(0.055 x 0.047 英寸)至 2.0 x 1.2 mm(0.079 x 0.047 英寸),最大高度低至 0.65 mm(0.026 英寸)。这些电感器可处理 1.9 至 6.4 A 的额定电流,额定工作温度范围为 -40°C 至 +125°C。

AOTA-B2012 系列中的一个范例是 Abracon AOTA-B201208SR11MT,这是一款 0.11 µH 的 SMD 微型模制电感器,额定电流为 5.6 A,饱和电流为 10 A(图 2)。其 DCR 为 13 mΩ,SRF 为 185 MHz。该器件采用 2.0 mm x 1.2 mm(0.079 英寸 x 0.047 英寸)封装,安装高度为 0.8 mm(0.031 英寸)。

图 2:AOTA-B201208SR11MT 是典型的 Abracon 微型模制电感器,采用 3 mm 以下 SMD 封装,可防止潮湿、灰尘、冲击和振动等环境因素的影响。(图片来源:Abracon)

图 2:AOTA-B201208SR11MT 是典型的 Abracon 微型模制电感器,采用 3 mm 以下 SMD 封装,可防止潮湿、灰尘、冲击和振动等环境因素的影响。(图片来源:Abracon)

AOTA-B201208S2R2MT 是 Abracon AOTA-B2012 系列中电感值较高的产品,电感值为 2.2 µH,额定电流为 1.8 A,DCR 为 130 mΩ,SRF 为 42 MHz。更高的电感需要更多的匝数,与 AOTA-B201208SR11MT 相比,增加了 DCR 并降低了额定电流和 SRF。封装尺寸与 AOTA-B201208SR11MT 相同,为 2.00 mm x 1.20 mm(0.079 英寸 x 0.047 英寸),高度为 0.8 mm(0.031 英寸)。

Abracon AOTA-B1412 系列的范例包括 AOTA-B141206SR33MT 和 AOTA-B141206SR47MT。这些微型模制电感器采用最小的封装,尺寸为 1.4 mm x 1.2 mm(0.055 英寸 x 0.047 英寸),封装高度仅为 0.65 mm(0.026 英寸)。AOTA-B141206SR33MT 的电感为 0.33 µH,额定电流为 3.5 A,DCR 为 32 mΩ,SRF 为 120 MHz。AOTA-B141206SR47MT 的电感为 0.47 µH,额定电流为 2.9 A,DCR 为 41 mΩ,SRF 为 115 MHz。

微型模制电感器的应用

尽管外形小巧,但 Abracon 微型模制电感器却能处理大功率,并具有较低的磁芯和传导损耗,同时提供出色的 EMI 屏蔽。当今世界对外形越来越小的电源转换器的需求空前,而这些特性使微型模制电感器成为满足这些需求的理想之选。

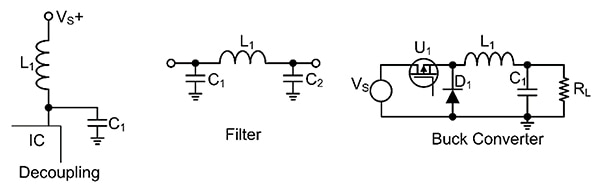

这些元器件的典型应用包括电源去耦、滤波和 DC/DC 转换器(图 3)。

图 3:Abracon 微型模制电感器的典型应用包括电源去耦、滤波和 DC/DC 转换器。(图片来源:Art Pini)

图 3:Abracon 微型模制电感器的典型应用包括电源去耦、滤波和 DC/DC 转换器。(图片来源:Art Pini)

电源总线中的去耦集成电路,利用电感器的频率可变阻抗结合电容器的互补阻抗特性,来衰减高频信号和噪声,从而使其与集成电路电源输入相隔离。低 DCR 和高 SRF 是重要的电感器特性。

滤波器控制信号路径的频率响应,并可配置为低通、高通、带通或带阻。电感器-电容器 (LC) 滤波器为无需有源器件的低功耗器件提供无源频率选择性响应。

电感器是 DC/DC 转换器中的主要储能元件。这些器件能在开关闭合时储存能量,在开关打开时释放能量。

结语

Abracon 微型模制电感器采用 3 mm 以下的紧凑型封装,具有模制电感器的优点。尽管外形小巧,但能应付较大功率等级,并具有较低的磁芯损耗和传导损耗,确保小型电子器件提供出色的电源完整性。

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。