Trends in LED Backlighting and Drivers for Mobile Devices and TVs

投稿人:DigiKey 欧洲编辑

2012-11-20

There is dramatic growth predicted for the use of LEDs over the next couple of years, and for the coming year at least, some of this growth can be attributed to backlighting, with applications in mobile devices such as smart phones, tablets and notebooks, as well as in TVs. In 2011, according to market research company Strategies Unlimited¹, LEDs for backlighting mobile devices made up the largest market segment at $3.4 billion. In the TV and monitor sector, LED revenue was estimated at $3 billion. Between them, backlighting accounted for half of the total LED market of $12.5 billion.

Figure 1: Sharp’s LC-LE640U series 60-inch edge-lit TV featuring LED backlighting.

Figure 2: Sony Ericsson Xperia pro MK16A Smartphone with LED-backlit Keyboard and Touchscreen, plus 8 MP Camera, Wi-Fi, and GPS.

However, the market is forecast to change its composition over the next few years, due to a number of concurrent trends that are already apparent. In the mobile phone market, for example, OLEDs are beginning to replace LED-backlit displays. In counterpoint, demand is predicted to continue to grow significantly for LED backlighting in tablets and associated mobile devices, such as high-resolution iPads and eBook readers which incorporate large numbers of LEDs.

LED backlighting for LCD TVs will continue to grow through 2012 and 2013, as the major manufacturers convert their designs. This has been slower than expected, according to market researchers, although some TV makers, such as Sharp, have already switched completely to LED backlighting. Governmental pressure and legislation in the US (Energy Star) and Europe (EuP) over power consumption of consumer electrical products, such as large TVs, is also influencing the move to LED backlighting. It has been reported that the power consumed by a large LCD screen, backlighting and associated circuitry, accounts for about two thirds of the total power consumed by a TV. Therefore, the power savings gained by shifting to LED backlighting are proving attractive. Fast switching and the ability to dim the lighting, when the picture itself is dark, for example, not only improve picture quality but save energy, too.

Flat screens, flat market

However, the TV sector of the LED backlighting industry is forecast to decline in unit terms in a couple of years’ time. Technology watchers anticipate that the number of LEDs per backlight will start to fall after 2012, as components become more efficient. Another influence on the market is the dramatic fall in prices of LED chips and modules as volumes continue to ramp up.

Looking at the overall picture of the LED market, as a result of these combined trends, Strategies Unlimited has slightly reduced its earlier growth predictions for the LED market. It is currently forecasting that the market for LEDs will remain flat at just over $13 billion through until 2014, with LED lighting then becoming the predominant application.

Market forecasts notwithstanding, the switch to LEDs in backlighting applications continues apace for now. Sharp, for example, is not only one of the many manufacturers of LCD TVs moving to LED backlit units. The company also supplies LEDs and modules for backlighting, and LED-backlit display units to OEMs. In various technical resources² including videos and white papers, Sharp explains that the move to LEDs is primarily due to customer demand, citing the advantages over CCFT (cold cathode fluorescent tube) methods of power savings, better low temperature operation, and environmental considerations (absence of mercury). In addition, Sharp claims LED-backlit displays have better shock and vibration tolerance and no RF output created by an inverter, which can induce interference.

Disadvantages now apparent in CCFT backlighting technology include reduced lifetimes, if operated at high temperatures, and the need for high ‘start-up’ voltage drivers. It is noted, however, that LED strings require a constant-current supply with current limiting to prevent thermal runaway. Integrated driver devices are making this challenge much simpler to solve. Improvements in LED technology, together with extended testing, are proving that LED-backlit LCDs are now better suited for higher temperature applications than they used to be, and better efficiency means they need to operate less at the upper end of the temperature range.

Edging back

Several manufacturers offer both edge-lit and direct-lit modules. Essentially, edge-lit modules are simpler, slimmer, and have been more cost effective for large units. Direct-lit modules, by contrast, use individual LED emitters which produce a number of benefits, including the ability to enhance the contrast dynamically and to produce a higher color gamut. The downside is that the module is larger due to heatsinking requirements, although it uses fewer, larger LEDs than edge-lit displays. Driver requirements for edge-lit and direct-lit backlighting units also vary. More will be explained further into the article regarding drivers.

Although there will always be a market for the high end, edge-lit displays, it has been reported that new designs are starting to incorporate the latest direct backlighting techniques, as they can be lower cost, thereby suiting developing markets.

Staying Sharp

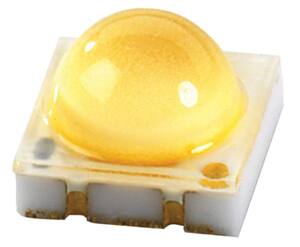

At the LED level for backlighting applications, Sharp Microelectronics offers the Pico Zenigata range of high intensity white LEDs. With a small footprint, these moderate-powered LEDs range from 0.2 to 0.5 W, delivering between 15 and 72.5 lumens. Available in one, two or three dice versions, the modules provide an operating life in excess of 40,000 hours at a normal operating temperature of 80°C.

Figure 3: An example of Sharp’s Pico Zenigata range of high-intensity LEDs.

The GM5BW97330A, for example, is a three dice ‘cool’ white LED module, operating at 20 mA per die to produce up to 17 lumens of light output. Warm and neutral white versions are also available. The company has recently introduced much higher luminous flux versions in the same family, with a three LED version radiating up to 72.5 lumens. Efficiency is quoted at 125 lm/W. All devices in the Pico Zenigata range offer high CRI (color rendering index) levels of better than 80 CRI.

For OEMs preferring a complete LED-backlit LCD module, Sharp offers a large family of units, ranging from 2.5 to 23.1 inches sizes, designed for a whole host of applications from small instrument displays, mobile and multimedia hand-held applications, up to larger tablet-size displays. The modules can include touch panel operation, LVDS interface, anti-glare filter, and a PWM-compatible driver for the LED backlight.

The LQ050A5DR01, for example, is a 5 inch landscape format, TFT liquid crystal color display with parallel interface. The LQ150X1LG91, meanwhile, is a 15 inch LED-backlit unit with LVDS interface. Many of the devices are same-size replacements of Sharp’s earlier CCFL displays.

OSRAM dedication

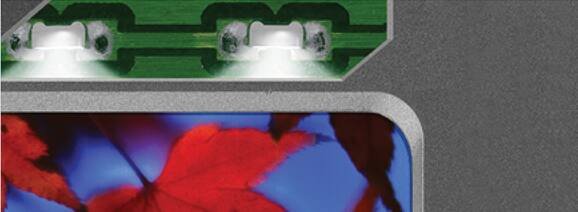

There is a wide range of choices in the OSRAM Opto Semiconductor LED portfolio for LCD backlighting applications. For small size mobile devices up to 5 inch diagonal, for example, the company recommends its Micro SideLED range of single LEDs, or for higher color gamut, its 3-pack modules with devices at specific wavelengths for incoupling into backlights. The SideLED range is available in a range of colors, including a high intensity (8300 K) white.

Figure 4: OSRAM’s latest Micro SideLED technology is ideal for backlighting displays and keypads for mobile phones, digital cameras and notebooks.

These ultra-slim, compact designs are also proving popular for notebook and tablet-sized displays, from 10 to 18 inch diagonal screens. Individual devices and modules come with profiles of 1 mm, 0.8 mm and even 0.6 mm.

For 5 to 10 inch instrument panel displays for industrial or automotive applications, it is worth considering OSRAM’s Ceramos multi-LED range. These compact modules are specified with a maximum current of 250 mA and a high color gamut. The devices have recently been used to backlight a 42 inch professional display, and have been reported to deliver accurate and true color reproduction, increased dynamic range and deep black levels as well as superior greyscale tracking.

For very low thermal resistance, the tried and tested Advanced Power TOPLED range may provide a good solution. This neutral white Advanced Power TOPLED model, for example, or the cool white version, with slightly higher luminous flux, are claimed to be ideal for light guide-based LCDs, and offer high ESD protection.

Finally, for the high end LCD TV market, OSRAM offers the OSLON LX range, with almost 100% outcoupling of light, and available in ultra-white or high color gamut versions. The devices are optimized for highest incoupling efficiency for edge-lit designs. Another option is the Golden Dragon Plus range, in warm, neutral or cool white versions. With high optical efficiency and permitted currents up to 1 A, these silicon-based devices have a long lifetime. Typical parts include the cool white 1 version, with a luminous flux of 123.5 lumens, and the neutral white version at 91.5 lumens.

Look out for new, more compact and higher efficiency models in OSRAM’s TOPLED range, designed for ultra-slim flat displays. Higher brightness at lower operating currents, and high current pulse mode will bring sharper images. Both ultra-white and multi-white versions have been developed. OSRAM is also claiming that TVs backlit by LEDs can deliver more brilliant colors, higher contrast, and color stability and consistency over a longer lifetime than CCFL techniques.

Seeing the light

Interestingly, OSRAM has also moved ahead in new backlighting applications, such as the large-scale advertising light box market. Although slow to take off initially, installations are now finding that by replacing old tube based systems with LED back-lit versions, maintenance costs can be reduced by as much as 90%. The figures demonstrate that the initial investment can soon be recouped by savings in maintenance, with a return on in investment of 1 to 2 years, depending on the scale of the application.

In addition, the switch to LEDs is delivering energy savings. In installations such as airports and shopping centers, this can be significant. OSRAM’s Golden Dragon Plus LEDs have been shown to deliver quality, reliability, and high performance over a number of years. Longer lifetimes of LED light sources contribute to reduce maintenance costs too.

The retail digital signage market is now beginning to grow rapidly as low energy, low maintenance solutions provided by LEDs have been shown to provide a cost effective, long-term light source.

Very Vishay

Recently announced by Vishay Semiconductors, among its broad range of LED and related optoelectronic products, is a series of super slim, ultra-bright LEDs contained in small 0603 surface mount packages. The VLMx1300 series incorporates its own CHIP-LED devices, and are offered in a range of colors as well as white. The white LED has a maximum luminous intensity of 180 mcd at a forward current of 5 mA and a maximum forward voltage of 3.15 V.

Applications for these devices include keypads of portable products such as navigation systems and displays for mobile phones, industrial control systems, and traffic displays. The white version is said to be particularly effective for backlighting displays for communications, audio/video and office equipment, as well as indoor and outdoor message boards. It is small enough to provide flat backlighting for LCDs, switchtops and keypad symbols.

Drive time

Any discussion of LED technologies should include some mention of LED drivers. According to the informative TechZone article³ from leading market research company Strategies Unlimited, the marriage of the driver electronics and the LEDs is the product. To take full advantage of the latest advances in LED technology, such as high brightness, color quality, greater efficiency, long life, small size and low cost, the choice of LED driver is critical.

There is a misperception among some designers that when it comes to LED drivers ‘one size fits all’, and that many drivers offer much the same features and performance. In fact, different applications require a different approach and the choice is huge. The LED vendors themselves are well aware of this, and most offer technical guidance, full or partial solutions, and work with dedicated driver partners where necessary. Driver design is evolving rapidly, not only to keep up with new applications and improved LED technologies, but also to improve features such as power factor correction, sophisticated dimming, uniformity and reliability.

At the root of driver misunderstanding is confusion about the terminology surrounding LED drivers. In simple terms, ‘the driver’ is all the circuitry surrounding the operation of the LED. A ’driver IC’ is one or more circuits dedicated to controlling the current and voltage in the driver circuit. While virtually every LED light application has a driver, not every driver has a driver IC. An ‘LED controller’, meanwhile, describes the circuit within the driver that controls the LED current. A ‘microcontroller’ however, when used in relation to LED applications, refers to the designer- or user-programmable element, added to manage the system or application, such as a timer or dimmer function.

Drivers are not always simple and are not ‘standard’. LEDs require constant, high current sources. When driving multiple, parallel strings (such as in large monitors or TVs), current and forward voltages need to be matched. Edge-lit displays require a high voltage boost topology, so high efficiency is essential. For direct-lit larger screens direct voltage is lower, but the screen is often zoned to allow local dimming. This requires more drivers.

An LED driver may be as simple as a resistor to limit the current, but such a design will not provide the control and uniformity required for backlighting applications. LED backlighting may be designed with strings of 10 or more LEDs in series, with a total string voltage of 60 V or more. Linear regulators and voltage (DC/DC) conversion circuits can be combined.

A new trend in portable devices today is that multiple LEDs are being installed for different applications, not only for backlighting a keyboard or display, but also to provide a camera flash or projection function, for example. Driver requirements can become more complex in such cases. In mobile devices with increasing functionality and higher integration, a power management IC (PMIC) may take over additional tasks such as battery charging, as well as LED driving. Such devices may not be listed under ‘LED drivers’, but may perform the task just as well.

Driver supply chain

There are dozens of manufacturers offering LED driver ICs. Some of these have a strong background in power conversion, linear regulators and associated circuitry. Some are LED manufacturers that have developed their own driver circuits. Many of these same manufacturers offer LED driver modules; effectively subsystems that are pre-engineered for specific applications, offering a choice of mounting styles, interface options and output configurations.

An example of a recently introduced LED driver IC that has hit the headlines, ideal for backlit displays in portable products, is the STLA02 from STMicroelectronics. The device can operate from battery supply voltages, including single lithium cells, ranging from 2.5 to 18 V, and deliver 20 mA to a six LED string. The driver uses a step-up boost DC/DC converter topology to support a 27 V supply to the LED stack. The switching design operates at 2.3 MHz. An integrated pulse-width-modulation dimming capability supports a 300:1 dimming range. An evaluation board is also available for trying out the device in potential applications such as smartphones, portable game players and GPS receivers.

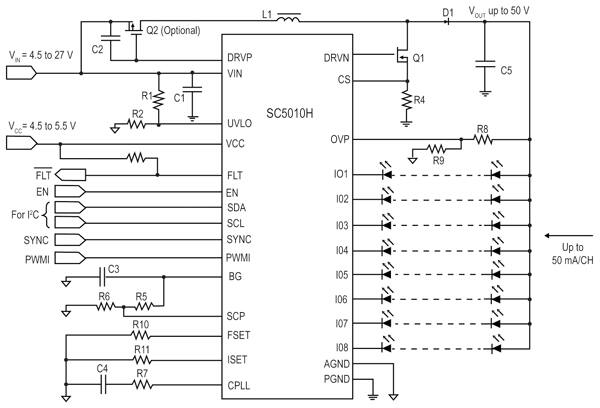

Another recent introduction, destined for notebook and tablet LED-backlit display applications, is the SC5010 phase-shifted LED backlight driver IC from Semtech Corporation. Operating from an input voltage of 4.5 to 27 V, the driver can drive eight strings of LEDs, each up to 30 mA. The key aspect of this device is that it employs a boost-based driver technology with a sophisticated loop architecture to enable it to be used with smaller 1 mm high inductors, instead of larger devices normally used in this type of application. As a result, thinner displays can be designed, down to just 4 mm.

Figure 5: Block diagram of the Semtech 5010 LED driver IC.

The phase-shift approach means that not all channels are powered on at any given time. According to the manufacturer, this results in reduced input and output capacitance and lower noise and EMI. The driver also supports a wide PWM-based dimming range, and includes over/under voltage and over temperature protection.

For the future, technology advances by some driver IC manufacturers are resulting in devices that can help improve thermal issues and energy wastage by sensing the mismatch in varying forward voltages of different LED strings. This is going to be particularly attractive for larger backlit screens in monitors and TVs.

Summary

Although LED lighting will be the dominant sector in the LED market within two years, LED backlighting will hold its own until then. This article has focused on the features and benefits of LED backlit displays for products varying in size from smartphones to TVs, along with highlighting the potential for growth in new multifunction applications including flash devices for integrated cameras, lighting for integrated miniature projectors, and retail advertising lightboxes.

A brief review of LED driver technology and emerging trends in this important sector complements the technical discussion. To illustrate the points made, some information on a number of recently introduced LEDs and drivers for backlighting applications has been included.

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国