Specialized ICs Facilitate Home Energy Management Systems Design

投稿人:电子产品

2012-10-10

For consumers, home energy centers offer the critical link in turning power utilization data into actionable information. Serving as the interface between the utility smart meter and individual energy-consuming products, these systems offer a means to monitor and control real-time energy usage. By collecting energy usage data from household products and combining these findings with utility rate data and other usage information from smart meters, these systems are able to provide consumers with specific information about their energy usage.

With this real-time energy usage information available, consumers can view overall energy consumption patterns and gain a better understanding about power usage by the residence as a whole, as well as by specific appliances. In turn, consumers can set these energy management systems to optimize household energy use – delaying appliances such as washers that consume large amounts of energy but whose operations can be deferred to take advantage of lower rates during off-peak hours.

This sort of ability to view actual energy usage easily is critical for energy conservation. In industry studies, direct feedback about energy usage through these kinds of systems resulted in energy savings ranging from 5 percent to 15 percent.¹ Although some consumers have expressed concerns about privacy issues, 97 percent of utility customers participating in a pilot program said they would continue using the devices in their homes and 71 percent said they had already changed their energy usage as a result of their ability to access data through the system.

For engineers, building cost-effective energy management systems has become simpler thanks to a broad range of ICs from manufacturers including Analog Devices, Cirrus Logic, Freescale Semiconductor, Maxim Integrated Products, Microchip Technology, NXP Semiconductors, STMicroelectronics, and Texas Instruments, among others.

Management subsystems

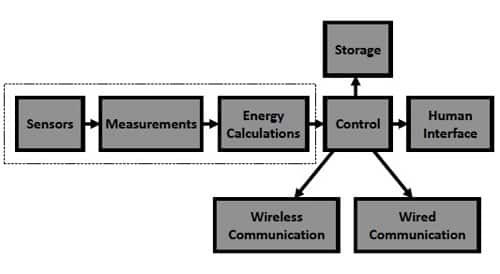

With the potential for widespread acceptance, energy management system developers face a challenge in building an appropriate level of functionality into these systems. The key elements of these systems typically include differing levels of capability for energy measurement, management, and communications (Figure 1).

In designing these systems, however, engineers face a broad set of requirements spanning energy measurement, communications, and host processing. In particular, because of the broad range of data communications capabilities they must support, home energy management systems rely on an embedded systems architecture that is based on an efficient CPU with diverse wireless and wired communications options necessary to communicate with energy-consuming products in the home.

Within the residence, energy-consuming products can report energy usage based on fixed values programmed into the appliance during factory characterization or based on real-time measurement and calculation of key energy parameters. In the latter case, engineers can take advantage of a broad range of specialized ICs that offer complete energy-measurement solutions.

Energy measurement

Energy measurement solutions typically need to address a few key energy-usage parameters, in particular active and apparent power.

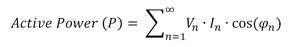

Instantaneous active power in a purely resistive load environment is simply V ∙ I. With the growth of reactive loads from compressors and motor-driven appliances, active power is ideally measured as the sum of Vrms ∙ Irms across all harmonics in the line frequency:

Where

Vn = Vrms at the nth harmonic in the line frequency,

In = Irms at the nth harmonic in the line frequency, and

φn = the phase difference between the voltage and the current at the nth harmonic.

Using the same factors, reactive power is then given by:

Apparent power is the power that can be delivered to the load, and is typically calculated as the arithmetic product of Vrms and Irms:

Finally, power factor PF is calculated by dividing active power by apparent power.

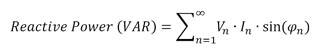

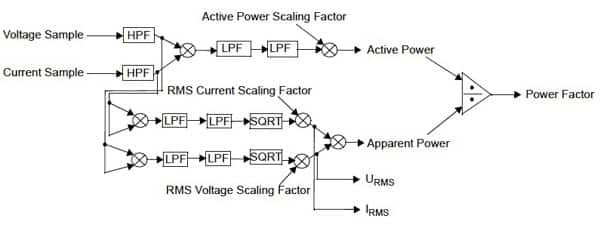

This method of measuring apparent power and deriving power factor is typically used in energy-measurement ICs such as the Microchip MCP3901 dual-channel analog front-end IC. The MCP3901 integrates two synchronous-sampling, delta-sigma ADCs and two PGAs, along with a complete signal chain for calculating active power and apparent power, among other energy parameters (Figure 2). Additional devices in this class include the Analog Devices ADE7763. Cirrus Logic CS5463 and STMicroelectronics STPM01 and STPM10 energy measurement ICs.

Figure 2: Specialized for energy measurement, available analog front-end (AFE) devices handle voltage and current measurement with on-chip ADCs and use built-in signal processing algorithms to calculate key energy parameters such as active and apparent power. This diagram illustrates the signal chain used in the Microchip MCP3901 to calculate these parameters. (Courtesy of Microchip Technology)

As the equations above illustrate, the accuracy of energy calculations depends on the accuracy of measurement of voltage and current. Consequently, engineers need to carefully consider the tradeoffs in commonly used approaches for current sensing including shunts, Hall-effect sensors, and current sense transformers. Shunts provide the lowest cost approach, but remain limited to relatively low currents. Higher-current sensors such as Hall-effect transducers and current sense transformers have faced concerns in the past about their effectiveness and stability, but more advanced devices and manufacturing methods offer improved accuracy and reliability for these devices - often combining the sensors themselves with compensating circuitry to ensure linear performance and reduced temperature dependency.

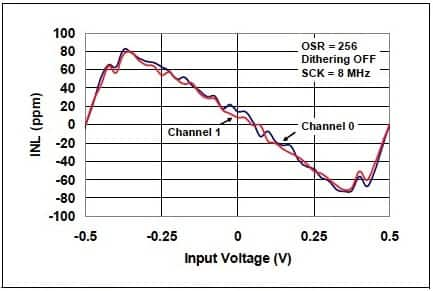

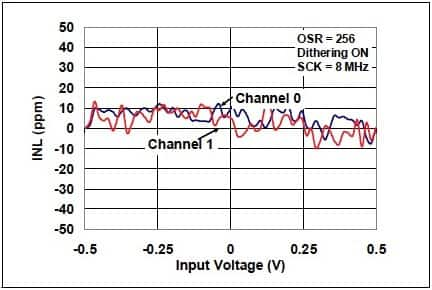

While sensor accuracy and stability continues to improve, another consideration is the accuracy of the data acquired from these sensors. One of the unique features of the MCP3901 is its use of a proprietary dithering algorithm to provide improvements in the signal-to-noise and distortion (SINAD) ratio. Dithering de-correlates idle tones on the input from the output, where they appear as white noise. As a result, this approach slightly increases the noise floor but offers the benefit of significantly improving total harmonic distortion (THD). Consequently, integral nonlinearity is improved (Figure 3), providing more accurate measurements needed in energy measurement applications.

Figure 3: Injected at the input to the single conversion chain, a dithering signal de-correlates idle tones, improving total harmonic distortion (THD) at a slight cost in elevated noise floor. The MCP3901 AFE IC uses this approach to improve integral nonlinearity shown here with dithering off (a) and dithering on (b). (Courtesy of Microchip Technology.)

Engineers can combine energy-measurement AFE ICs such as the Microchip MCP3901 with an MCU such as the PIC18F87J72 to provide a dedicated energy monitoring system designed for individual appliances such as clothes washing machines and dryers.

A number of devices combine AFE capabilities with an on-chip MCU and LCD drivers to support energy metering design requirements, including those for simple home management systems. For example, the Analog Devices ADE7569 is built around an 8052 core and includes energy measurement and LCD driving functionality, simplifying design of energy metering applications. Similarly, the Maxim Integrated Products 71M6541D combines an 8051 core with AFE functionality to support a full range of power measurements.

Communications capabilities

In selecting dedicated energy measurement AFEs or even MCU-based integrated energy measurement ICs, engineers must also address communications capabilities required for home energy management strategies. Indeed, centralized home systems require diverse, flexible communications capabilities to exchange data with smart appliances, lighting systems, and smart meters, among others. Of the wide range of options available to engineers, powerline communications and ZigBee have emerged as essential elements in a home energy management system.

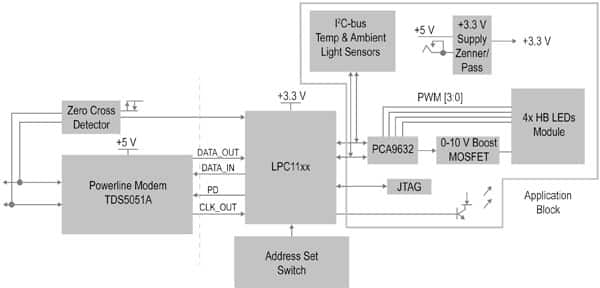

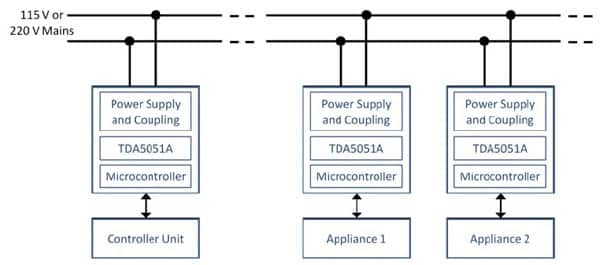

Engineers can use devices such as the NXP TDA5051A powerline modem IC, which transmits and receives digital signals on standard power lines. Designed to ensure reliable communications over noisy power lines, devices such as the TDA5051A work in tandem with a microcontroller such as the NXP LPC1114 MCU, a 50 MHz, 32-bit MCU based on the ARM Cortex-M0 processor. Using these types of devices, engineers can typically implement sophisticated control systems such as lighting control systems with only a few additional components (Figure 4, which also shows an NXP PCA9632 LED Driver).

Figure 4: Using an NXP TDA5051A powerline modem, LPC1114 MCU, and PCA9632 LED driver along with a few additional components, engineers can quickly implement home automation subsystems such as this lighting control system. (Courtesy of NXP Semiconductors.)

In a home environment, control systems comprising the MCU and powerline modem would be connected to power-consuming appliances and devices, exchanging energy usage and control management data with the central home energy management system. In operation, the MCU would collect energy usage data from an energy measurement AFE and write the data to the powerline modem. In turn, the modem would encode the data and transmit it over the power line. Conversely, the powerline modem would decode control commands from the central management system and pass them along to the MCU to complete operations directed by the central controller (Figure 5).

Figure 5: Powerline modems provide a convenient communications method for home automation systems. While measurement and control units within individual appliances report on energy usage via power lines, a central controller uses the same medium to issue commands to optimize energy utilization within the individual appliance or home product. (Courtesy of NXP Semiconductors)

ZigBee has emerged as a leading communications protocol in energy management, and engineers can select from a variety of available devices. Besides a broad array of standalone 2.4 GHz transceivers such as the Microchip MRF24J40, engineers can find highly integrated solutions such as the Freescale MC1322x family supporting the ZigBee stack and ZigBee Smart Energy Profile.

Designed to simplify ZigBee deployment, the MC1322x family of platform-in-package (PiP) solutions combines a low-power 2.4 GHz radio frequency transceiver, 26 MHz 32-bit ARM7TDMI-S core-based MCU, hardware acceleration for both the IEEE 802.15.4 MAC and AES security, and associated MCU peripherals into a 99-pin LGA PiP. Freescale includes 128 Kbytes of flash, mirrored into on-chip RAM for stack and application software. Along with its 80 Kbytes of ROM, the device's memory complement allows engineers to use the nonvolatile store for boot software, as well as standardized IEEE 802.15.4 MAC and communications stack software.

Host-based systems

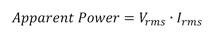

Although engineers can find highly integrated devices for energy measurement and communications, more sophisticated home energy systems need to support not only multiple communications methods, but also a variety of peripherals for storage and operator interface features including local keypad access, local network access, and wide-area network access through smartphones.

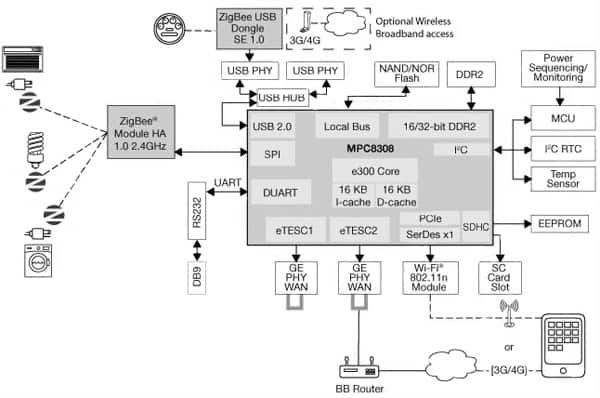

In this case, engineers can choose peripheral-rich MCUs such as the Freescale MPC8308. Supporting clock rates up to 400 MHz, this device combines an e300 core for handling more complex application requirements involving diverse peripherals. Indeed, the MPC8308 includes a PCI Express controller, two Ethernet controllers supporting data rates up to 1,000 Mbits/s, an SDRAM controller, DMA controller, two I²C controllers, dual UART, USB, SPI, and GPIOs (Figure 6).

Figure 6: More sophisticated home energy management systems combine communications and extensive peripheral support with a powerful CPU core to support display-rich applications for home users. (Courtesy of Freescale Semiconductor.)

In fact, engineers can choose from a variety of MCU-based design options to create home energy management systems targeted at specific price points. Beyond the simpler management systems possible with the MCU-based single-chip solutions mentioned previously, engineers can move to more advanced processors to support greater application functionality. For mid-level systems, engineers can combine more advanced MCUs such as the TI Stellaris Cortex M3, which is able to support a broader range of graphics processing requirements.

At the high end, these systems are no less than sophisticated host systems based on a full OS such as Linux, running on more powerful CPUs such as the TI AM1808 32-bit ARM9 RISC microprocessor. The AM1808 combines a high-performance pipelined core with data and program memory management units with table look-aside buffers and separate 16 Kbyte instruction and 16 Kbyte data caches.

Conclusions

Home energy management systems provide the critical feedback functionality needed to optimize energy utilization at the level of the individual consumer and even appliance. Using a broad range of specialized ICs for energy measurement, engineers can quickly and easily deploy energy-aware peripherals, able to communicate energy usage to centralized controllers using integrated communications ICs. For the central management system itself, the combination of integrated MCU-based ICs, midrange MCUs, and high-end processor cores offers engineers a rich set of options in tuning hardware capabilities to home management system functionality.

Reference:

- The Effectiveness of Feedback on Energy Consumption, University of Oxford, Environmental Change Institute, 2006

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。

中国

中国