Sensors Play a Key Role in Monitoring Active Volcanoes

投稿人:电子产品

2015-09-25

Volcanoes and volcanic activity fascinates us. With greater regularity, sensors are being used to gather and analyze data so that accurate volcanic activity forecasts can be created. Consider, for example, some recent newspaper headlines: “NASA Armstrong leads team to test effects of volcanic ash on aircraft engine,” and “Seafloor sensors record possible eruption of underwater volcano,” as well as “Monitoring volcanic eruptions with a wireless sensor network.” Sensors are sufficiently capable, reliable, accurate and, based on data provided by sensor fusion—powerful enough to tackle such a mountain of data.

Estimates are that there are approximately 1,500 potentially active volcanoes worldwide—and they are able to cause a lot of damage, even where it might not be obvious. Over the past 15 years more than 80 commercial aircraft have encountered volcanic ash in flight and at airports, according to the United States Geological Survey (USGS). Seven of these encounters caused in-flight loss of jet engine power, nearly resulting in a crash.

To further investigate the causes behind these incidents, since 2011 NASA has partnered with the 412th Air Force Test Wing, the Air Force Research Laboratory, the Federal Aviation Administration (FAA), Boeing Research & Technology, Pratt and Whitney, General Electric Aviation, and Rolls-Royce Liberty Works to test and evaluate new engine health-management technologies through the implementation of the Vehicle Integrated Propulsion Research (VIPR) project.

Sensors are now being used to test the amount of volcanic ash that aircraft can handle. With the use of a C-17 and two F117 engines provided by the Air Force Research Laboratory, the current stage of testing will introduce increased amounts of Mount Mazama volcanic ash into one of the engines to assess how the health monitoring sensors and their associated software can detect and report a problem. According to a principle investigator of the VIPR project working on the challenge, “We’re looking at technologies that will be able to identify aircraft entry faults at the beginning stages and we want to be able to identify and diagnose them, and also how they will change over time,” said John Lekki of NASA’s Glenn Research Center and a VIPR principle investigator. Lekki indicates that the investigation team will use the data from multiple sensors including vibration, emissions, and fiber-optic temperature sensors throughout the engine to identify and diagnose the issues.

In addition to airborne dangers, seafloor sensors are recording the eruptions and potential eruptions of underwater volcanoes. Take, for example, the University of Washington’s deep-sea observatory and the eruption of a volcano off of the coast of Oregon1. The students are working around the clock to help a specialized deep-sea robot2 swap out sensors and platforms for annual maintenance and help scientists and engineers check in on other instruments, which include a high-definition video camera and deep-sea water and DNA sampler.

As part of the study, seismic activity was recorded by eight seismometers that measure shaking up to 200 times per second around the caldera and at the base of the 3,000-foot sea mount. Measurements included the height of the caldera, pressure of the water overhead, and the removal of the effect of tides and waves so as to calculate position accurately.

Not only can seismic changes be measured in advance of a volcano quake, they can also be used to measure changes in the undersea landscape post-quake. Now, wireless sensor networks are being used to detect earthquakes as well, as shown in Figure 1.

Figure 1: A wireless-sensor network can be used to monitor seismic data on an active volcano. (Courtesy of Harvard University, illustration by Matt Welsh and others)

Sensors at work

Sensors used for such scientific purposes run the gamut from motion tracking to pressure sensors, from inertial measurement units to those created specifically for seismic monitoring. Following are just a few sensors that are representative of those used to measure and even predict when a powerful volcano will erupt.

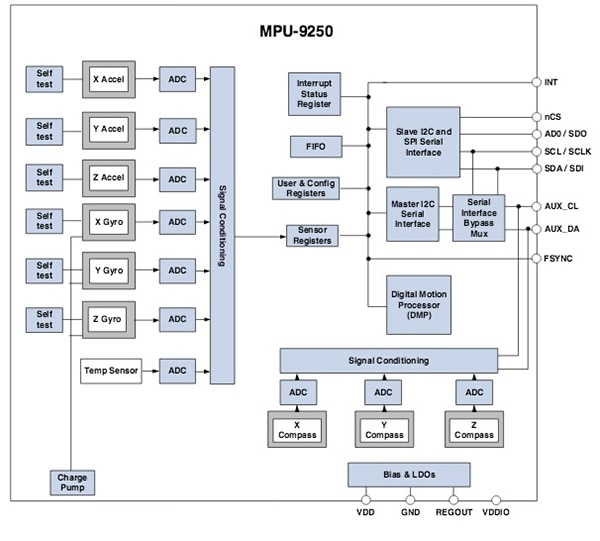

Motion tracking plays an important role in volcano as well as earthquake measuring applications. The InvenSense MPU-9250, for example, is a multi-chip module consisting of two dies integrated into a single QFN package. One die houses a 3-Axis gyroscope and a 3-Axis accelerometer. The other die houses a AK8963 3-Axis magnetometer from Asahi Kasei Microdevices (AKM) Corporation. All told, the MPU-9250 (Figure 2) is a 9-axis device that includes a Digital Motion Processor (DMP) engine supporting advanced motion processing; the DMP offloads computation of motion-processing algorithms from the host processor. The DMP acquires data from accelerometers, gyroscopes, magnetometers and additional third-party sensors, and processes the data. The resulting data can be read from the DMP’s registers, or can be buffered in a FIFO. The DMP has access to one of the MPU’s external pins, which can be used for generating interrupts.

Figure 2: The MPU-9250 block diagram. (Courtesy of InvenSense)

Typically, InvenSense reports, motion-processing algorithms should be run at a high rate, often around 200 Hz, in order to provide accurate results with low latency. This is required even if the application updates at a much lower rate; for example, a low-power user interface may update as slowly as 5 Hz, but the motion processing should still run at 200 Hz. The DMP can be used as a tool in order to minimize power, simplify timing, simplify the software architecture, and save valuable MIPS on the host processor for other uses in the application.

The MPU directly provides complete 9-axis MotionFusion output. It is designed to interface with multiple non-inertial digital sensors, such as pressure sensors, on its auxiliary I2C port and it features three 16-bit analog-to-digital converters (ADCs) for digitizing the gyroscope outputs, three 16-bit ADCs for digitizing the accelerometer outputs, and three 16-bit ADCs for digitizing the magnetometer outputs. For precision tracking of both fast and slow motion, the part features a user-programmable gyroscope with a full-scale range of ±250, ±500, ±1000, and ±2000°/sec (dps), a user-programmable accelerometer with a full-scale range of ±2g, ±4g, ±8g, and ±16g, and a magnetometer with a full-scale range of ±4800 μT.

The Honeywell 6-D Motion Variant 6DF-1N6-C2-HWL Inertial Measurement Unit’s (IMU) sensors (Figure3) are designed to provide motion, position, and navigational sensing from a durable single device. Using MEMS technology, it can sense translational movement in three perpendicular axes (surge, heave, sway) and rotational movement about three perpendicular axes (roll, pitch, yaw).

Figure 3: The Honeywell 6DF IMU provides motion, position, and navigational sensing from a single device. (Courtesy of Honeywell)

The 6 DF (six degrees of freedom) Series IMU measures the motion of the target onto which it is attached and delivers the data to the equipment’s control module using the industry-standard CAN SAEJ1939 communications protocol. Available in two versions, the 6DF-1N6-C2-HWL is tolerant of vibration and rugged environments, allowing for optimum performance in harsh environments, with a small reduction in accuracy. Its aluminum housing protects the device from damage due to stones, dust, dirt, and humidity, allowing for use in harsh and outdoor environments. It is also corrosion-resistant to minimize susceptibility to deterioration, which is often experienced in saltwater environments.

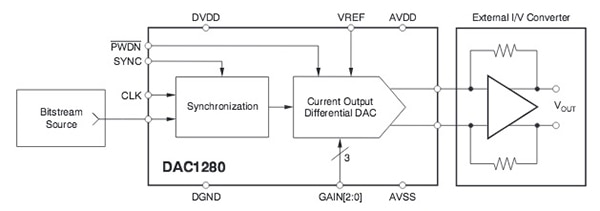

The Texas Instruments DAC1280IPW (Figure 4) is a low-distortion digital-to-analog converter well-suited for seismic monitoring. It provides a high-accuracy output signal from a bitstream input. The device achieves very high linearity in a small package while dissipating only 18 mW. Together with the company’s ADS1281 and ADS1282 ADCs, the devices create a test and measurement system that meets the exacting demands of seismic monitoring equipment.

Figure 4: The DAC1280 Block Diagram. (Courtesy of Texas Instruments)

In seismic monitoring systems three gain control pins in the DAC1280IPW set the output range in 6 dB steps from 0 dB to –36 db (± 2.5 V to ± 0.039 V differential). The attenuation ranges match the gains of the ADS1282 for testing at all gains. The DAC uses a reference voltage and bias resistor to set the full-scale output. The resistor can be adjusted to fine trim the DAC full-scale. The SYNC pin aligns the input data sampling to the CLK phase. A power-down pin shuts down the device when not in use. The DAC1280 is available in a small, 16-pin TSSOP package and is fully specified for operation over –40°C to +85°C temperature range with a maximum operating temperature of +125°C.

Motion and thermal observation are among the many on-the-ground techniques used for volcano surveillance and for the monitoring of ongoing volcanic activity. For example, each node of the Mount St. Helens in-situ sensor network is equipped with a seismometer to detect earthquakes, a GPS receiver to pinpoint location and measure small ground deformations and an infrasonic sensor to detect volcanic explosions. This article has examined some of the sensors that are well suited for use in volcano monitoring and discussed how these sensors are being put to work.

For more information about the parts discussed here, use the links provided to access product pages on the DigiKey website.

References

- “Students, researchers at sea working on recently erupted deep-sea volcano” University of Washington Today

- Ropos (Remotely Operated Platform for Ocean Sciences) Deep Seas Robot

免责声明:各个作者和/或论坛参与者在本网站发表的观点、看法和意见不代表 DigiKey 的观点、看法和意见,也不代表 DigiKey 官方政策。